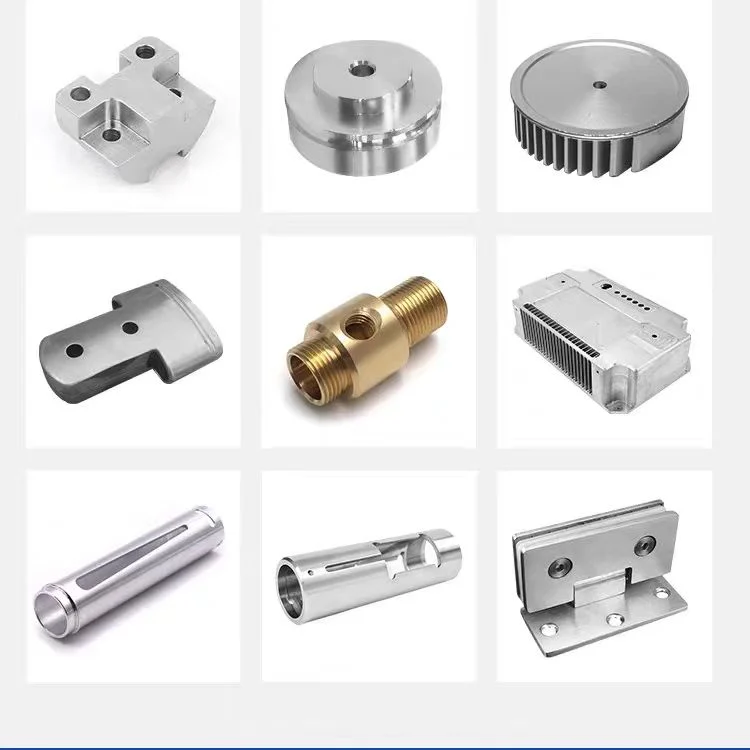

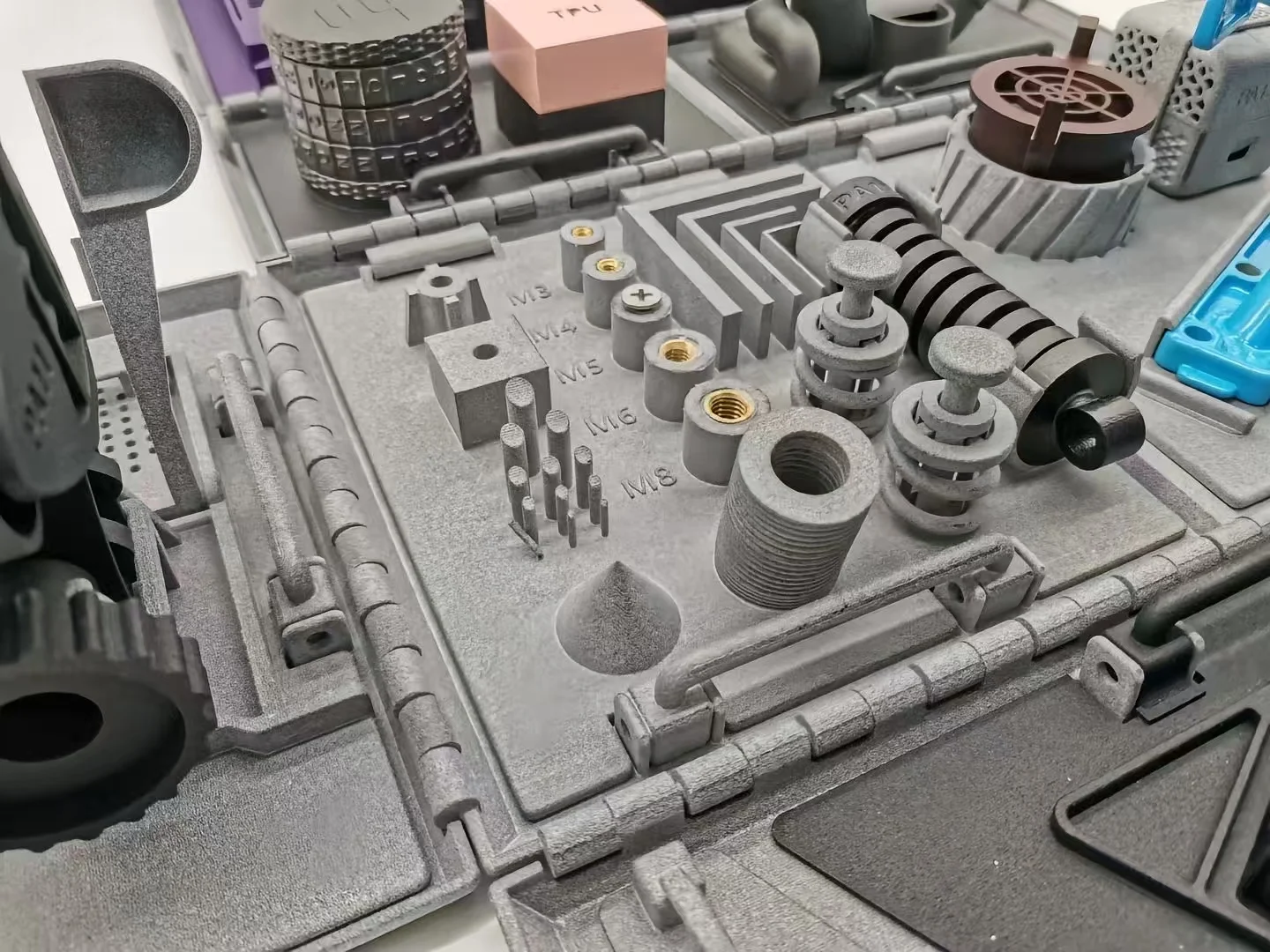

From Prototype to Consistent Supply

Develop and refine prototypes precisely, setting the foundation for

stable, scalable production. Ensure alignment on specifications and

quality targets to transition smoothly into consistent supply.