ZSCNC Industry Solutions

Delivering high-accuracy CNC machining and custom components designed to optimize productivity and reduce downtime. Trust ZSCNC for scalable, innovative manufacturing solutions.

Why Industries Choose ZSCNC

ZSCNC provides unparalleled precision, efficiency, and customization services to various industries, accelerating your manufacturing success.

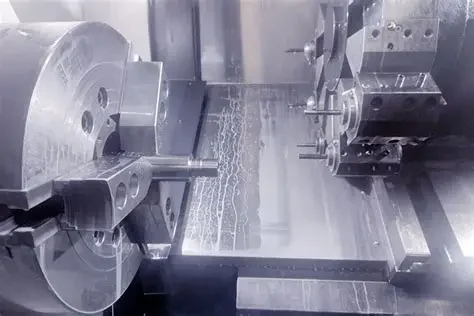

Precision Engineering at Scale

ZSCNC utilizes cutting-edge CNC technology to ensure consistently high tolerance manufacturing, minimizing defects and waste.

Customized Solutions for Diverse Industries

Our modular processes adapt to automotive, aerospace, medical, and more, providing tailored parts that match industry specifications.

Reliable Supply Chain Integration

ZSCNC integrates seamlessly into your supply chain with on-time delivery, real-time communication, and scalable capacity.

Advanced Technology

Leveraging the latest CNC machinery ensures precise cuts and superior surface finishes for demanding applications.

Expertise & Support

Our engineering team collaborates closely with clients, providing guidance from design to production.

Sustainable Manufacturing

Committed to eco-friendly processes, ZSCNC reduces material waste and invests in energy-efficient operations.

Core Service Industry Matrix Overview

Energy

Durability and operating condition adaptation oriented. Typical needs: components that can withstand complex conditions such as high temperatures, high pressures, and corrosion. We focus on: material processing experience adapted to operating conditions and precision machining of critical areas.

Our Advantages

- Industry-leading precision with consistent quality guarantee.

- Advanced CNC technology and a skilled workforce.

- Flexible production capacity customized to your needs.

- Comprehensive quality control from prototyping to delivery.

Multi-Industry Engineering Collaboration Process

Cross-Industry Expertise

Our engineers integrate knowledge across automotive, aerospace, and manufacturing sectors for superior design innovation.

Integrated Design & Manufacture

From prototype to production, we synchronize engineering and manufacturing teams reducing time to market.

Collaborative Innovation Process

ZSCNC enables seamless communication through expert teams to deliver tailored engineered solutions efficiently.

Industry Grade Quality Compliance Capabilities

At ZSCNC, we deliver uncompromising industry-standard quality and compliance. Our advanced processes ensure precise, certified manufacturing.

Certified Quality Processes

Our multi-tier quality assurance adheres to industry-leading standards like ISO 9001 and AS9100. Every component undergoes rigorous testing for dimensional accuracy and durability.

Compliance and Traceability

Full material traceability and documentation support regulatory and client requirements. We maintain detailed records to ensure compliance across every batch.

-

Precision Engineering

State-of-the-art machinery delivering consistent accuracy within tight tolerances.

-

Robust Documentation

Complete reporting and certification for each manufacturing run.

-

Experienced Quality Team

Dedicated professionals ensuring compliance throughout production.

-

Advanced Inspection

In-house metrology lab equipped for detailed component verification.

Typical Application Scenarios

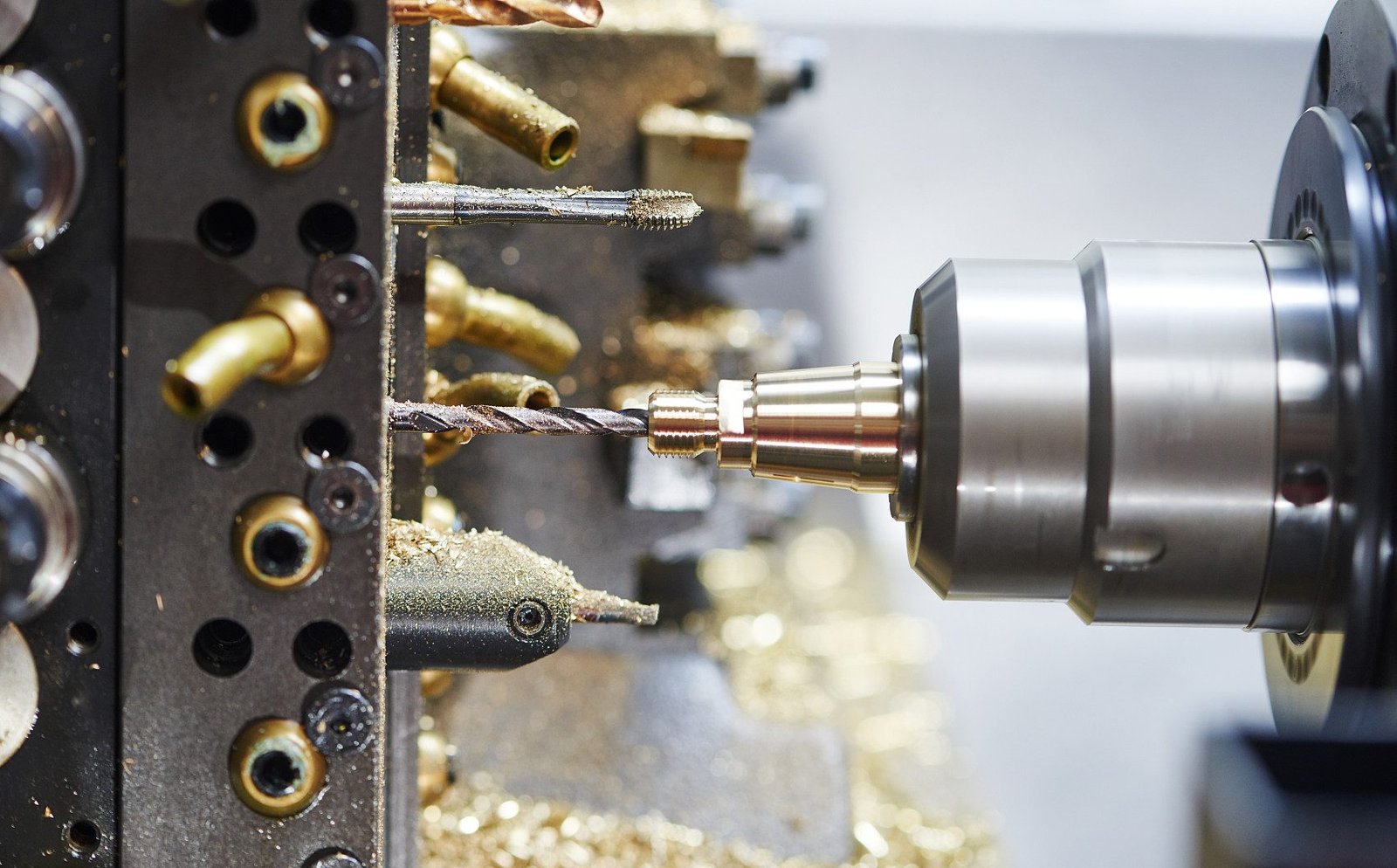

Precision CNC Machining

Deliver highly accurate CNC parts tailored for aerospace, automotive, and industrial equipment.

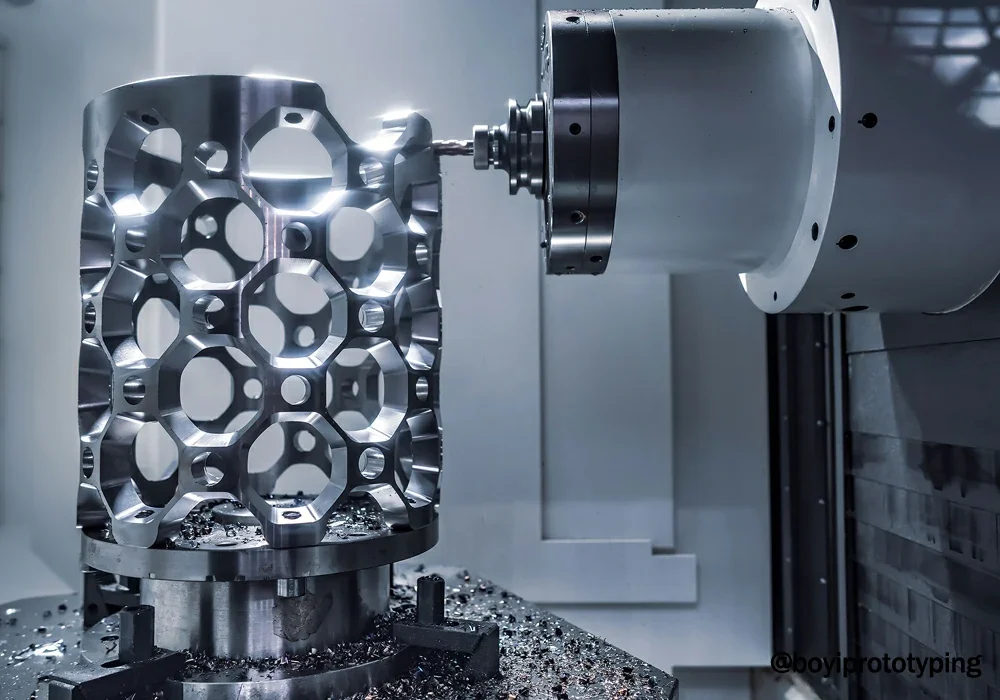

High Precision Industrial Components

Manufacture complex, high-tolerance parts for medical devices and defense industries.

Custom CNC Machining Solutions

Provide tailored machining services for prototyping and production runs across industries.

Metal CNC Machined Parts

Produce durable metal components suited for heavy machinery and construction applications.

Precision CNC Milling

Expert CNC milling for complex profiles used in electronics and consumer product manufacturing.

Skilled CNC Machining Workforce

Employ experienced machinists to ensure quality and efficiency in all CNC projects.

Future Oriented Industry Collaboration Directions

Innovative Partnerships

Leverage cross-industry expertise to accelerate technology adoption and drive sustainable growth.

Advanced Manufacturing Integration

Implement precision machining combined with digital workflows for streamlined operations.

Data-Driven Decision Making

Utilize analytics and IoT data for predictive maintenance and enhanced product quality.