Precision CNC Machining for Aerospace Excellence

At ZSCNC, we deliver aerospace-grade precision CNC machining with unmatched accuracy and reliability. Our advanced processes reduce production time and cost while optimizing part performance.

Types of Aerospace Components and Typical Applications

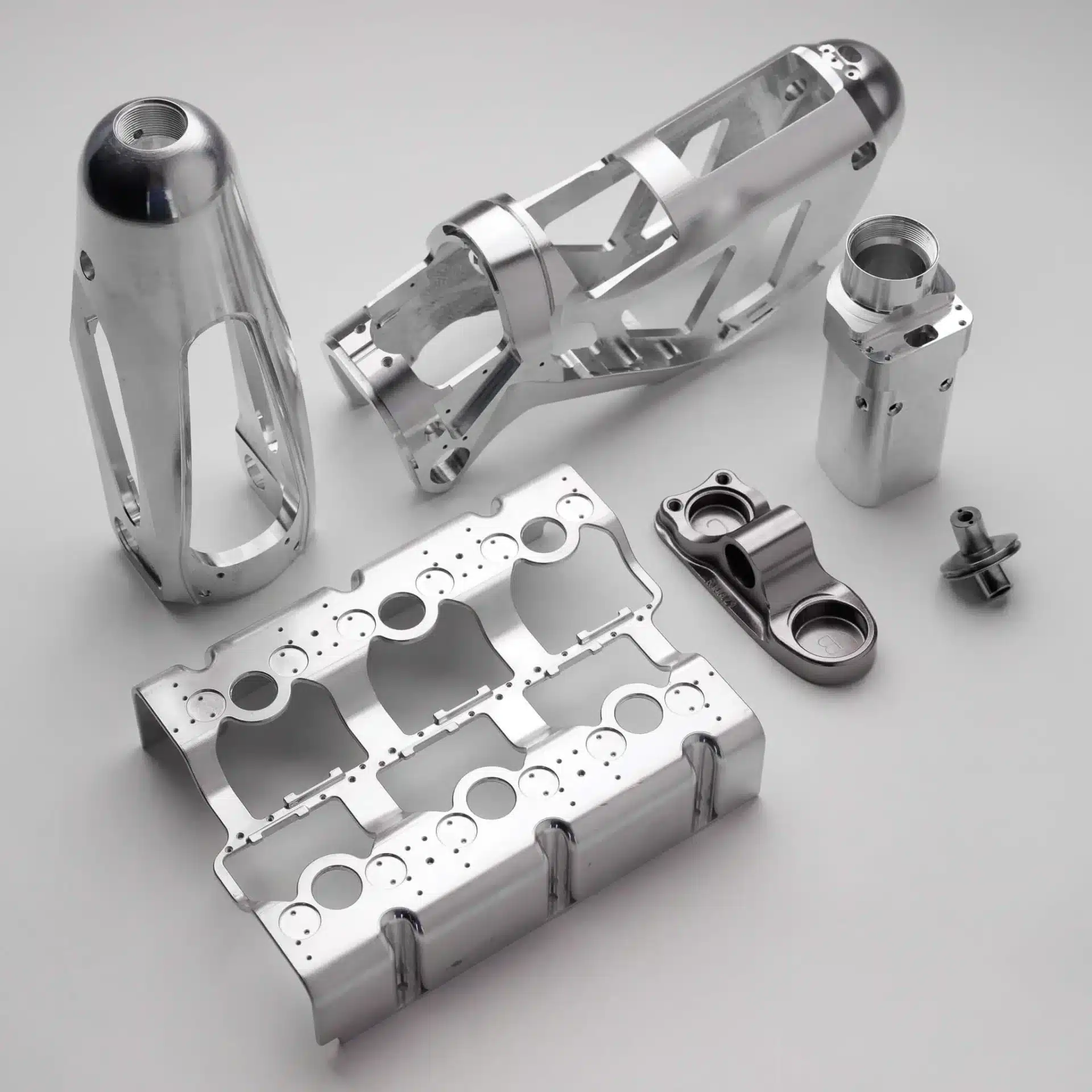

Structural Components

Critical framework parts ensuring aircraft integrity and durability.

Commonly used in fuselage, wings, and tail assemblies to provide strength under load.

Drive and Motion Parts

Precision components enabling controlled motion and power transmission.

Includes gears, shafts, and actuators vital for engine and control systems.

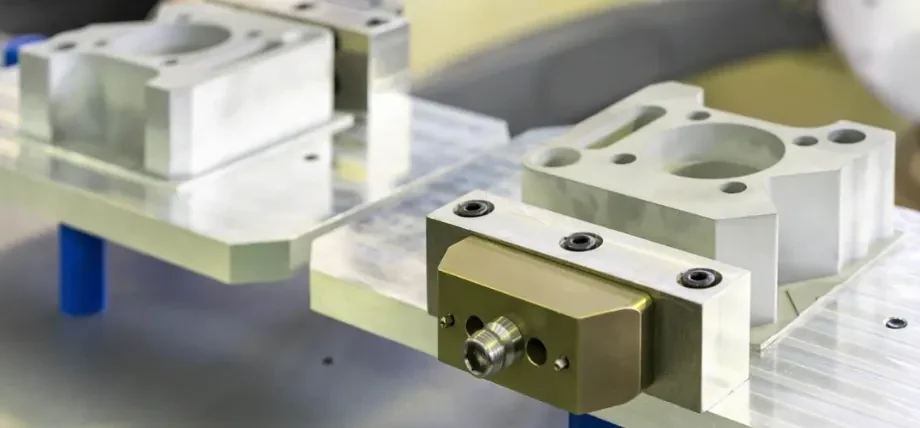

Fastening and Connection Elements

High-strength bolts, rivets, and fasteners for reliable assembly.

Ensure structural integrity while allowing maintenance and component interchangeability.

Functional and Cabin Accessories

Interior components enhancing passenger comfort and system functionality.

Includes panels, controls, and environmental accessories tailored for safety and usability. For inquiries, please visit our contact page.

Material Processing Scope for Aerospace Applications

-

Aerospace-grade Aluminum Alloys

Precision material processing for aluminum with heat treatment ensuring optimal strength-to-weight ratios.

-

Stainless Steel and Corrosion-resistant Alloys

Advanced finishing and corrosion protection processes tailored for aerospace standards.

-

Carbon Steel and Alloy Steel

Custom fabrication to meet high durability and fatigue resistance requirements.

-

Specialty Materials and Collaborative Processing

Integrated workflows combining expert machining, welding, and surface treatments.

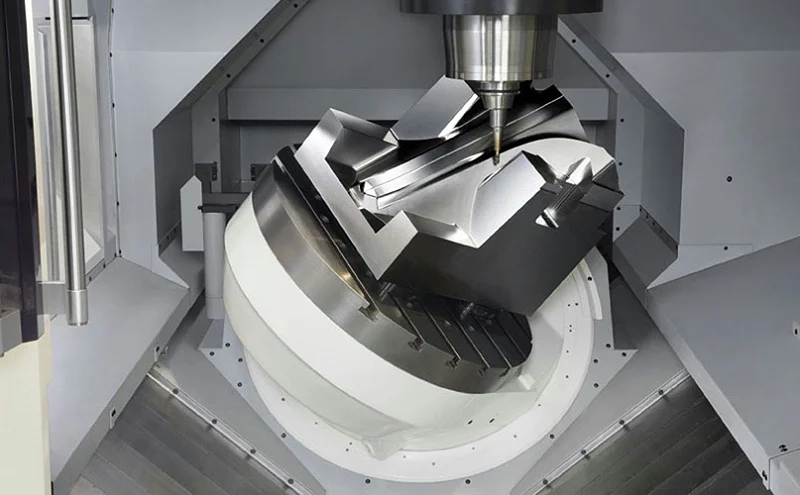

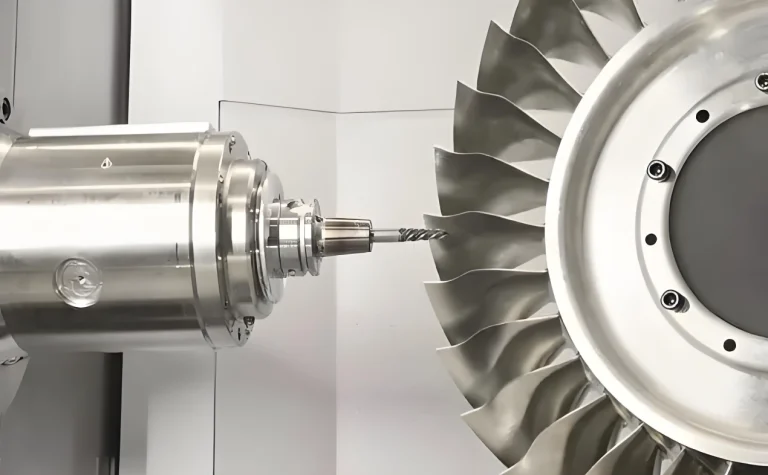

Aerospace-Dedicated CNC Process Capabilities

At ZSCNC, our multi-axis precision CNC machining delivers stable dimensional control critical for aerospace parts. We specialize in fine hole and thread processing, ensuring optimal surface quality and precise post-processing allowance for your components.

- Multi-axis CNC machining tailored for aerospace tolerances

- Stable dimensional control for consistent quality and performance

- Fine hole and thread processing with exacting precision

- Enhanced surface finish with post-processing allowance management

Quality Control and Traceability System for Aerospace Projects

Comprehensive Quality Control Checkpoints

ZSCNC implements rigorous quality control checkpoints throughout aerospace project lifecycles, ensuring each component meets exacting standards. Our systematic approach reduces defects and guarantees consistency.

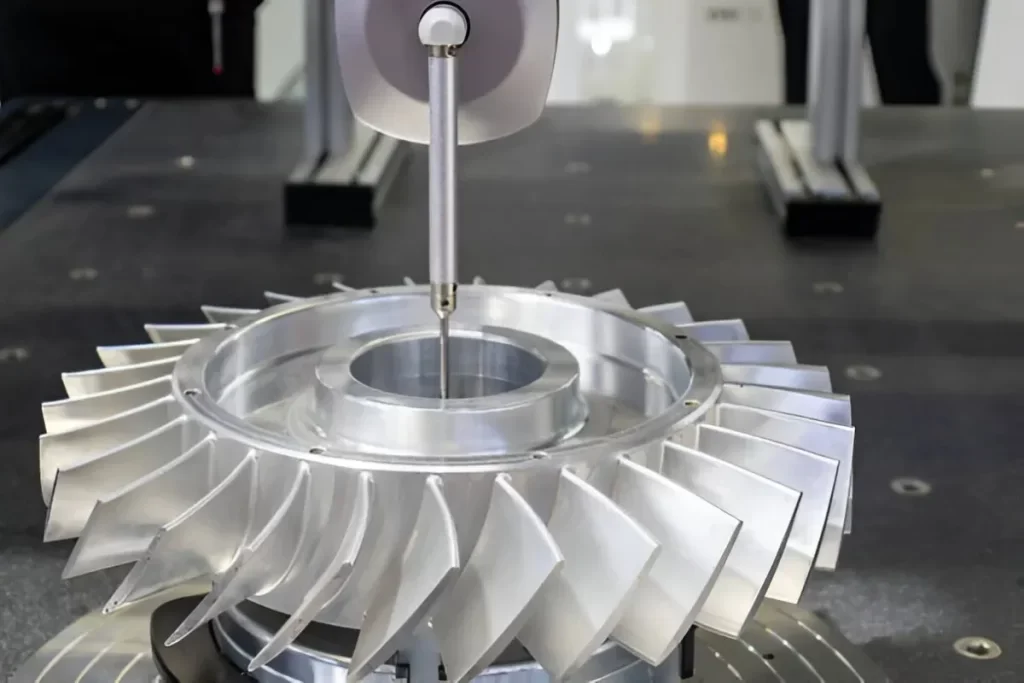

Advanced Measurement Equipment and Methods

Utilizing state-of-the-art measurement technologies, we deliver precise inspections and dimensional verifications for aerospace components. Our methods adhere to industry-leading accuracy requirements.

Documentation and Record Keeping

Every quality checkpoint is documented rigorously with secure record keeping to ensure traceability. This facilitates audits and supports regulatory compliance in aerospace manufacturing.

Customer Feedback Loop

We integrate customer feedback to continuously improve quality protocols. Our feedback loop drives innovation and aligns production quality with client expectations. Learn more about our company profile and manufacturing process to understand our commitment.

Collaborative Project Management Services for Aerospace

ZSCNC delivers seamless coordination to accelerate aerospace prototyping and production using advanced CNC machining services. We emphasize clear communication and technical precision to ensure project success.

- Technical Drawing & Requirement Review: Thorough analysis to align concepts and specifications.

- Rapid Prototyping & Validation: Fast development and testing to reduce time to market.

- Small Batch Multi-variant Production: Flexible manufacturing tailored to diverse aerospace components.

- Ongoing Optimization & Cost Management: Continuous improvements focused on efficiency and budget control.