Metal Materials Spectrum & Applications

Metal Categories Matrix

- Lightweight Structural Metals: Aluminum alloys

- High-Strength Corrosion-Resistant Metals: Stainless steel, titanium alloys

- Functional Metals: Brass, copper

- Structural and Tool Metals: Carbon steel, tool steels

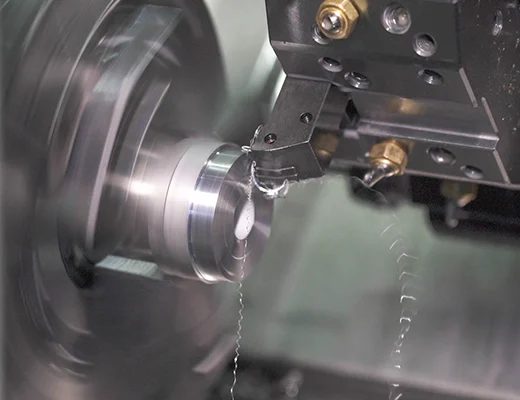

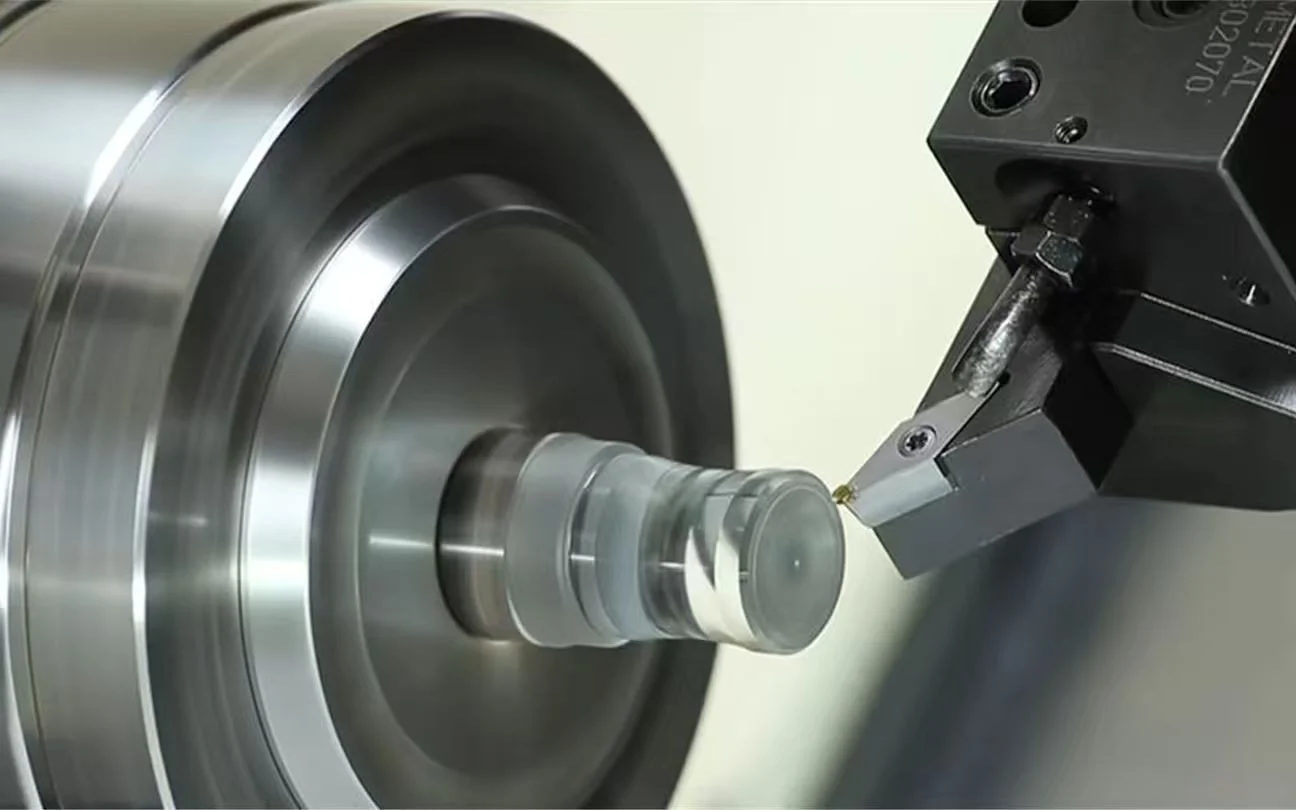

Machining Processes

Explore various machining techniques essential for metalworking.

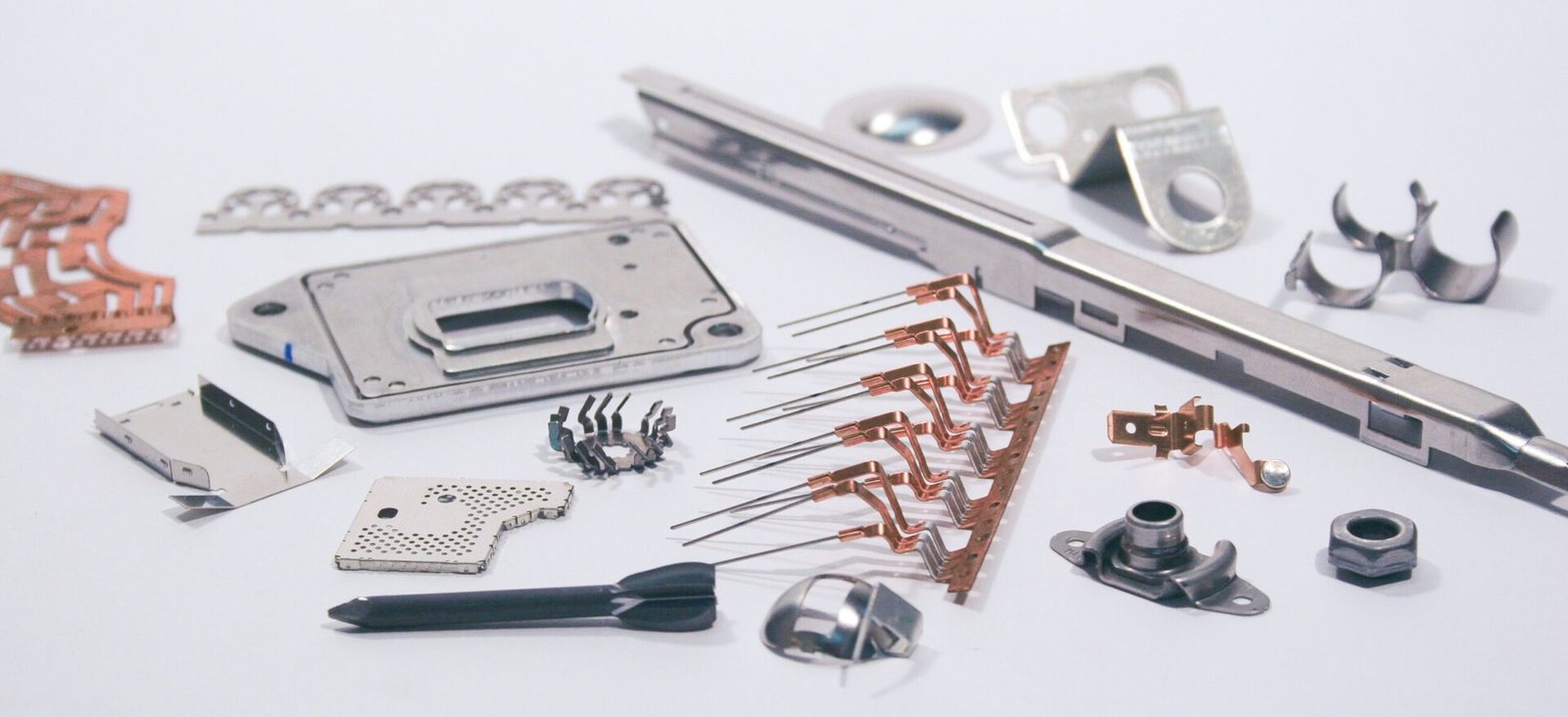

Project Application Types

- Individual Metal Components

- Multi-Metal Structural Assemblies

- Prototype Development

- Ongoing Mass Production

Metal Material Application and Selection Logic

Structural and Weight Balance Needs

For applications requiring weight reduction, dynamic response, and transportation cost efficiency, choose aluminum alloys and lightweight steels. These metals deliver strength while minimizing load.

- Aluminum alloys for lightweight durability

- Lightweight steels optimized for strength and weight balance

High Strength and Long-Term Reliability

For load-bearing, stress-critical, or shock-exposed components in motion, select high-strength stainless steel, structural steel, or specialized tool steels to ensure durability and longevity.

- High-strength stainless and structural steels

- Specialized tool steels for shock resistance

Corrosion Resistance & Environmental Adaptability

Outdoor, chemical, and humid environments demand corrosion-resistant materials to maintain aesthetic stability and functional integrity. Select corrosion-resistant stainless steel and corrosion-proof alloys.

- Corrosion-resistant stainless steel

- Corrosion-proof alloy solutions

Conductivity and Functional Requirements

For electrical connectors, heat dissipation, and sensor interfaces, copper and brass provide reliable conductivity and thermal responsiveness critical to system performance.

- High conductivity copper

- Brass for electrical and thermal function

High-End Precision and Specialty Industry Use

Medical, aerospace, and precision mechanisms need premium alloy metals for exceptional safety and performance in demanding safety-critical scenarios.

- Premium alloy metals for highest precision

- Tailored metals engineered for aerospace and medical standards

Metal Machining Capabilities & Dimensional Accuracy

Machinable Size Range

At ZSCNC, we expertly machine components from micro precision parts to mid-sized structural elements, including shafts, plates, and housings. Our advanced equipment offers versatility and reliable size capability. We offer various milling machining services for diverse needs.

- Micro precision components with micron-level accuracy

- Mid-sized structural parts and shaft-like profiles

- Thin plates, complex housings, and detailed geometries

Surface Finish & Post-Processing Compatibility

Achieve superior surface finishes with precise control on roughness and quality classes. We support heat treatment, coating, and plating processes, ensuring optimal interfaces for durability and performance. Additionally, our turning machining capabilities optimize surface quality.

- Surface roughness optimized for functional and aesthetic needs

- Support for heat treatment, coating, and plating applications

- Compatible with diverse post-processing treatments

Batch Consistency & Production Scalability

ZSCNC ensures prototype batches and medium-volume production maintain consistent quality through rigorous process monitoring and equipment maintenance programs. Our expertise in five-axis machining supports complex scalable production.

- Prototype to medium-scale runs with repeatable precision

- Advanced process control minimizing thermal deformation

- Equipment maintenance for consistent output and uptime

ZSCNC combines dimensional accuracy, surface excellence, and scalable production capabilities to meet your highest metal machining standards.

Quality Control and Inspection Standards for Metal Materials

At ZSCNC, we ensure rigorous raw material control, including sourcing certification, batch traceability, and international compliance. Our processes adhere to Japanese, American, and European client standards.

Chemical composition and mechanical properties are continuously monitored. Dimensional sampling and first-piece inspections guarantee consistent quality for turning, milling, drilling, and other machining operations.

We actively control metal distortion, burr formation, and surface defects through process monitoring. Final inspection includes full key dimension verification and functional validation such as fit, function, and assembly of moving parts.

Comprehensive inspection reports document compliance with international quality standards, providing transparency and trust in every batch we deliver.

Typical Industries and Metal Parts Application Examples

Industrial Equipment & Automation

Mechanical brackets, transmission components, mounting bases, and motion system elements designed for robust industrial automation.

Electronics & Electrical Devices

Precision metal terminals, connector housings, electrical brackets, and heat dissipation supports optimized for electrical performance and durability.

Transportation & Structural Components

High-strength fasteners, connectors, structural blocks, and precise positioning assemblies engineered for transportation industry demands.

Custom Machinery and Prototype Fixtures

Functional brackets, test jig parts, specialized tooling, and custom metal stamping components tailored for prototyping and bespoke machinery.

Global Collaboration Workflow for Metal Machining

Requirements & Drawing Confirmation

Receive 2D/3D files and material specs. Clarify technical tolerance and advise on material substitutions for cost efficiency in CNC machining.

Prototyping & Evaluation

Assess sample cycle timing per metal complexity. Confirm dimension, fit, and finish before mass production with advanced milling machining.

Mass Production & Progress Tracking

Schedule orders and batches. Manage turning machining, inspection, inventory, and supply with real-time progress tracking.

Packaging & International Logistics

Utilize rust prevention and shock-resistant packaging. Ensure secure shipping to Japan, USA, and Europe.

Technical Expertise & Cost Impact Advisory

Expert evaluation of machining complexity and material substitutions minimizes cost impact without compromising quality.

ZSCNC's integrated global workflow streamlines your metal machining production from initial specs to final delivery.

Custom Metal Services & Engineering Support

At ZSCNC, we provide expert engineering review and manufacturability feedback to optimize your metal projects. Our design assessment identifies risks, offers improvement suggestions, and structural amendments for ease of machining while reducing cost and maintaining function.

We recommend material grades and specifications tailored to your environment and strength requirements. Our focus on procurable, easier-to-machine materials ensures efficient production without compromise using advanced CNC machining services.

Benefit from long-term project assistance including process documentation, inspection criteria, and ongoing production support. Our data-driven design and material optimizations enhance quality and reduce downtime by integrating precise milling services.