Precision CNC Machining Solutions by ZSCNC

Streamline your manufacturing process with our expert CNC milling and custom metal fabrication services. Reliable, efficient, and tailored for your business.

ZSCNC Core Service Framework

Precision CNC machining services and fabrication services designed to meet complex manufacturing needs with unmatched quality and efficiency.

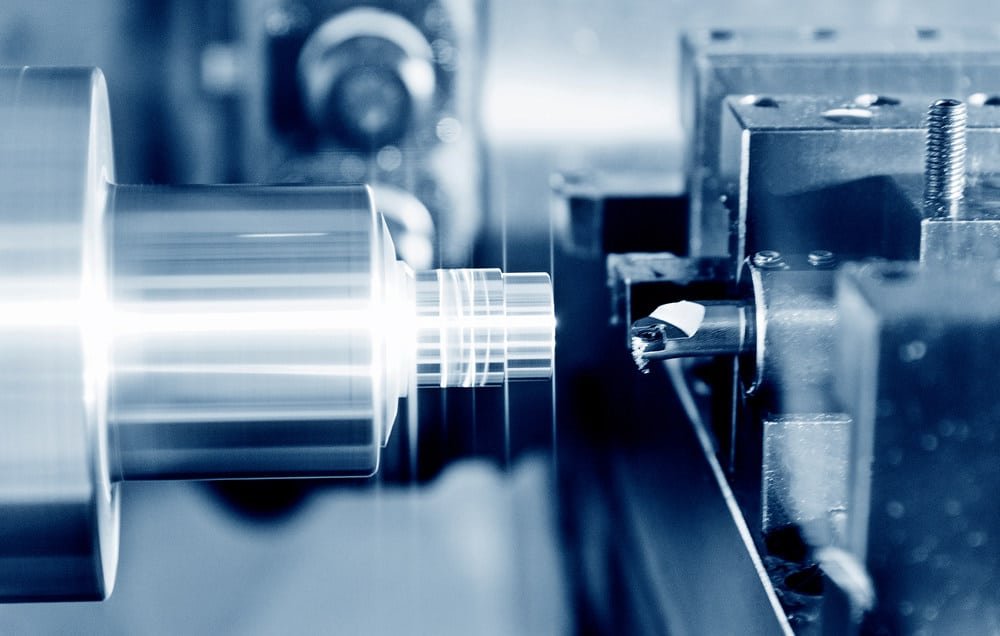

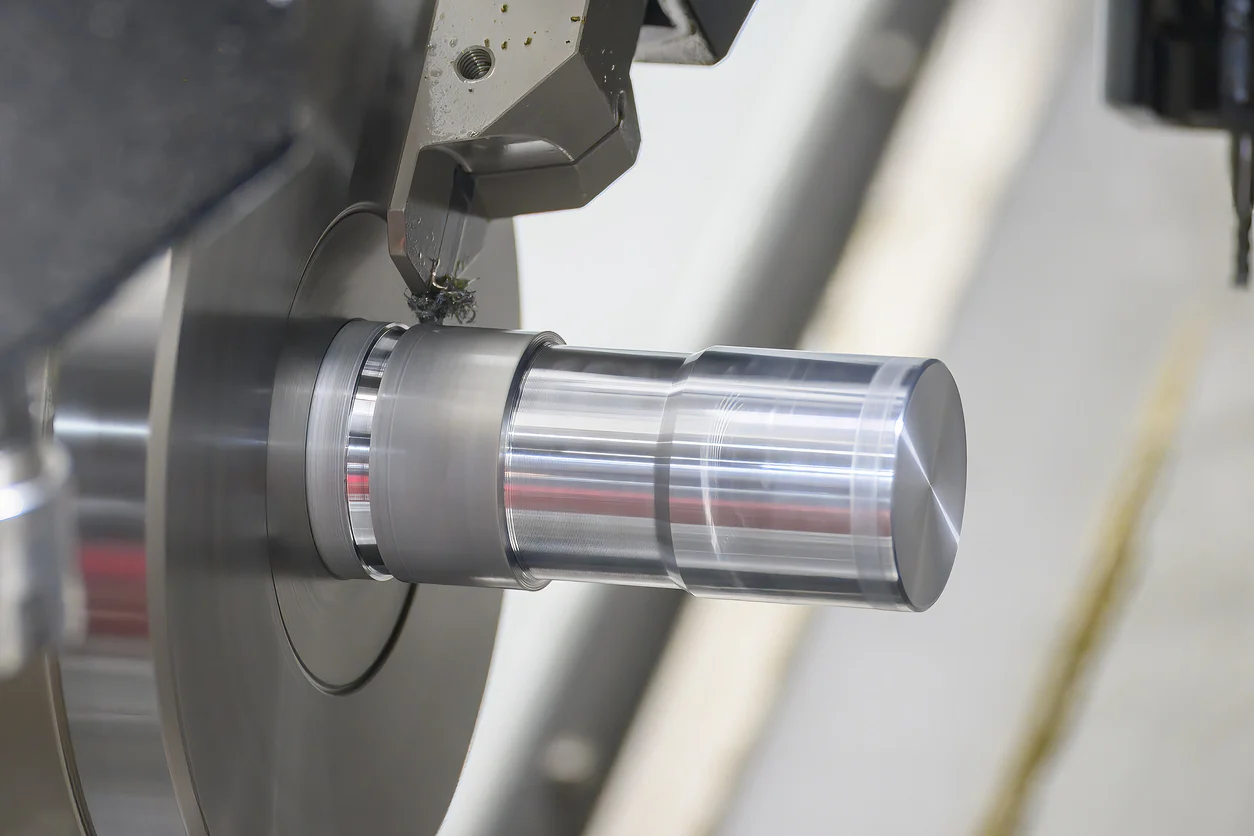

Precision CNC Machining

Delivering micron-level accuracy on a wide range of metals and plastics using advanced CNC milling, turning, and drilling including milling and turning.

Custom Metal Fabrication

Comprehensive fabrication services including cutting, bending, and assembling stainless steel, aluminum, and other alloys.

Welding and Assembly

High-quality welding techniques—MIG, TIG, and spot welding—delivering durable assemblies meeting tight tolerances.

Surface Finishing

Advanced finishing processes including anodizing, polishing, and coating to enhance part performance and aesthetics.

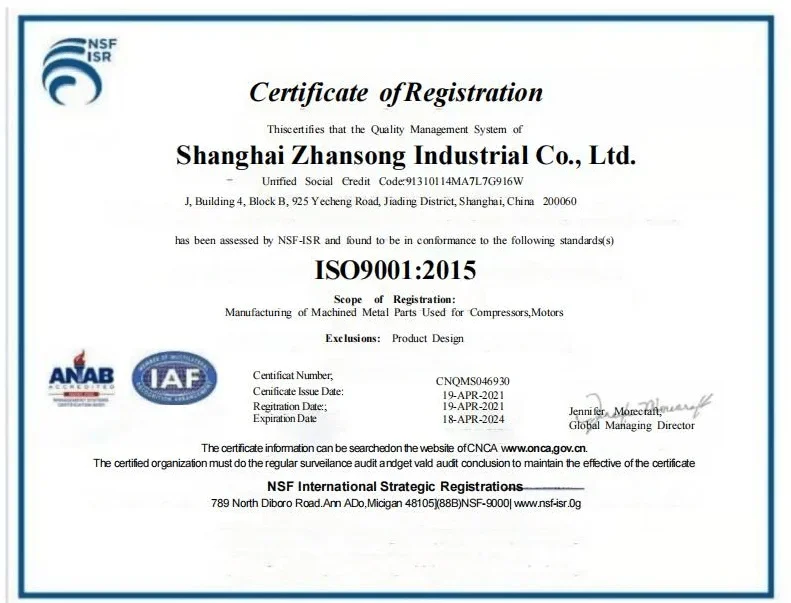

Quality Assurance

Stringent inspection protocols ensuring every part meets ISO standards and customer specifications with 100% traceability.

Structural Fabrication

Robust steel fabrication tailored to heavy-duty applications, including structural supports, frames, and customized assemblies.

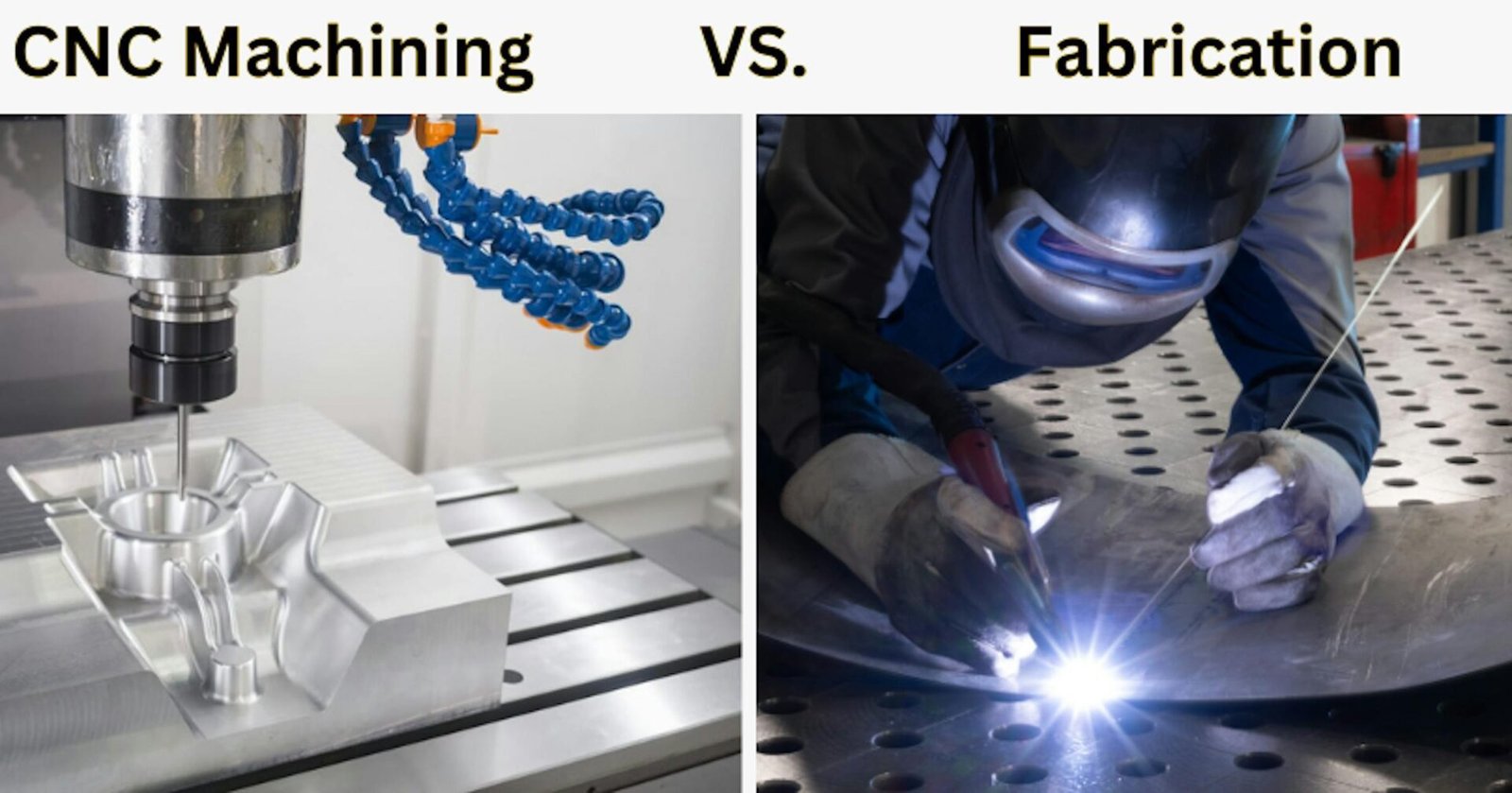

CNC Machining VS Fabrication

Explore the key differences between CNC machining and fabrication to determine the best manufacturing process for your project.

CNC Machining

CNC machining is a subtractive manufacturing process that uses computer-controlled machine tools to precisely remove material from a solid block.

Fabrication

Fabrication involves various processes like cutting, bending, welding, and assembling to create structures or products from raw materials.

Key Differences

The primary differences lie in precision, material usage, and complexity. CNC machining offers high precision, while fabrication is suited for larger structures.

Precision CNC Machining Services by ZSCNC

At ZSCNC, we deliver high-precision CNC machining solutions tailored for industries demanding exceptional quality. Our advanced equipment and skilled operators ensure exact tolerances on every part.

- High accuracy machining with tolerance as tight as ±0.005 mm

- Rapid prototyping and short lead times to accelerate your production

- Wide material compatibility including steel, aluminum, and specialty alloys

- Comprehensive quality inspection for every order ensuring full compliance

Fabrication and Forming Services Overview

ZSCNC delivers expert fabrication and forming solutions tailored to your manufacturing needs. Our precision processes maximize quality and efficiency.

Custom Metal Fabrication

From prototyping to high-volume production, our advanced equipment ensures consistent, precise metal parts for diverse industries.

CNC Machining & Forming

We use state-of-the-art CNC machining services to create complex geometries with tight tolerances, optimizing both form and function.

Welding & Assembly

Our certified welders deliver strong, reliable joins with meticulous attention to detail, supporting robust final assemblies.

Streamlined Processing Workflow & Project Collaboration

Optimized Workflow for Maximum Efficiency

At ZSCNC, our processing workflow ensures precision and speed, reducing bottlenecks at every stage while maintaining rigorous quality control.

Seamless Project Collaboration

Collaborate effortlessly with our integrated platform, enabling transparent communication, status tracking, and real-time updates on your projects.

Precision Meets Reliability

Our skilled team uses advanced CNC machining technologies to deliver consistent results that meet your specifications and timelines.

Quality Control and Equipment Strength

At ZSCNC, we prioritize rigorous quality control to ensure every component meets precise integrity standards. Our state-of-the-art equipment guarantees exceptional strength and durability.

- • Comprehensive inspections integrated throughout production phases.

- • Advanced machinery engineered for maximum structural strength.

- • Real-time monitoring ensures consistent quality and reduces defects.

- • Comprehensive documentation supporting compliance and traceability.

Typical Applications and Project Types

Precision CNC Machining

High-tolerance components produced for aerospace, automotive, and medical devices using state-of-the-art CNC technology. Learn more on our about page.

Custom Steel Fabrication

Tailored steel structures and assemblies for construction, industrial, and commercial projects with precise craftsmanship. For inquiries, visit our contact page.

Expert Welding Solutions

Advanced welding techniques delivering strong, durable joints for transportation, energy, and heavy equipment industries.

Diverse Industry Applications

Serving aerospace, defense, medical, automotive, and energy sectors with customized manufacturing and metalwork.

Large-Scale Production Runs

Efficient and cost-effective manufacturing for bulk orders, ensuring consistency and stringent quality control.

Welding and Fabrication Projects

Specialized welding and fabrication tailored for complex constructs and repair work across multiple industries.

Delivery Capability and Cooperation Models

Reliable Delivery Capabilities

ZSCNC ensures timely delivery through advanced precision machining and a scalable production process. Our cutting-edge facilities and dedicated logistics team minimize lead times while maintaining quality and compliance.

Flexible Cooperation Models

Partner with us through tailored models: on-demand production, long-term contracts, or joint development projects. We adapt to your supply chain needs ensuring transparent communication and shared growth. Explore our solutions designed to fit diverse industries.

State-of-the-Art Equipment

Utilize industry-leading CNC machines for consistent precision and efficiency in every order.

Collaborative Project Management

Transparent workflows and dedicated points of contact ensure smooth cooperation with clients.

Scalable Solutions

From prototyping to mass production, ZSCNC scales with your business needs without sacrificing quality.