Real-Time Inspection

Continuous monitoring of laser cutting to detect deviations immediately. Minimizes defects and ensures consistent quality throughout production.

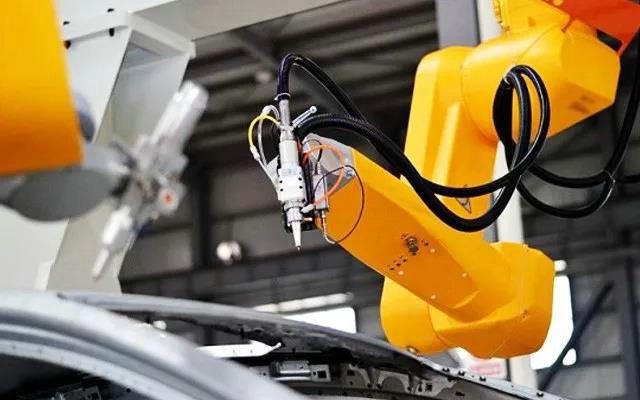

ZSCNC delivers industry-leading laser cutting with unmatched accuracy and speed. Our advanced technology ensures clean edges and minimal material waste for all your fabrication needs.

Optimize your production with precise cuts on a wide range of metals and materials. Experience expert craftsmanship combined with scalable automation.

Precision laser cutting technology drives superior efficiency in integrated manufacturing systems, supported by professional services.

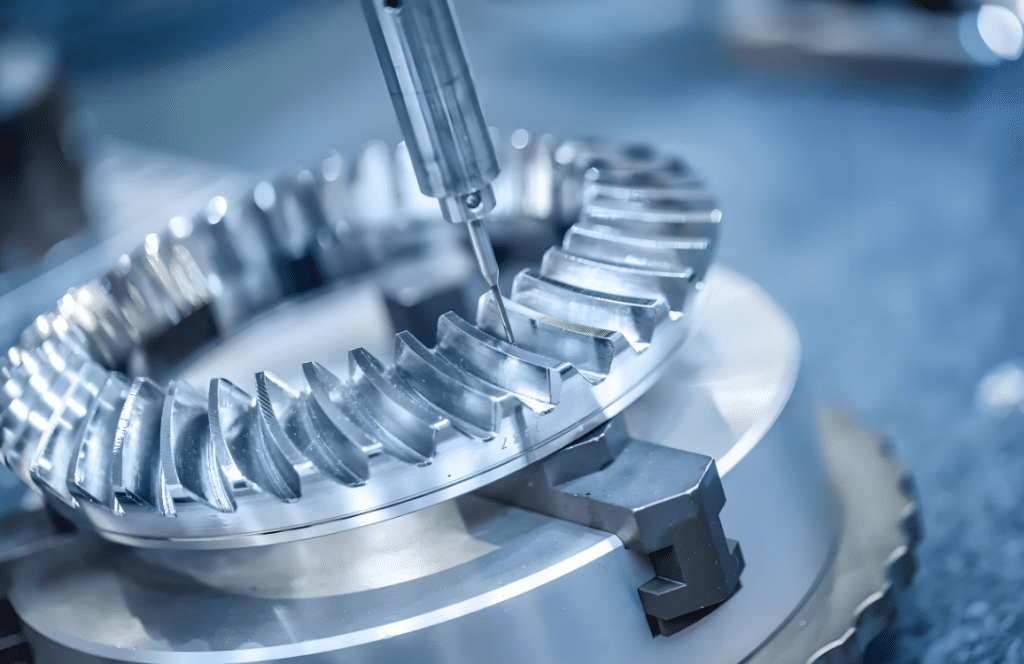

Achieve micron-level tolerances consistently across complex geometries and materials.

Process metals, alloys, and composites without mechanical stress or tool wear.

Reduce cycle times and waste while maximizing throughput in manufacturing workflows with expert CNC machining services.

Precision CNC machining services for EU automotive components and motorsport parts with tight tolerances ISO certification and fast delivery.

Precision CNC aluminum machining for high performance parts in Europe with ISO certified quality 5 axis capability fast delivery and tight tolerances

High precision CNC machining for packaging machinery parts with food grade materials and fast delivery to Netherlands and Belgium

Aluminum CNC milling service for German machinery parts with tight tolerances certified alloys fast delivery and custom prototypes

Advanced technology for precision manufacturing across industries and applications.

Our comprehensive five-axis machining services ensure smooth integration within complex manufacturing workflows.

At ZSCNC, our precision laser cutting process is optimized using finely tuned parameters to ensure the highest levels of accuracy, repeatability, and material quality. For related advanced cutting technologies, see our waterjet cutting services.

Compatible with stainless steel, aluminum, titanium, and more—delivering consistent precision across materials.

Achieve smooth, burr-free edges with optimized laser parameters, reducing post-processing time and cost.

Equipped with CNC-controlled laser cutters for precision and consistent production on all part sizes.

Metals offer unmatched strength, durability, and thermal resistance. For detailed insights on metal properties and fabrication, visit our metals & sheet metal fabrication services page. Ideal for applications demanding structural integrity and longevity.

Plastics excel in lightweight applications with good chemical resistance and electrical insulation properties.

ZSCNC guides you in choosing metals or plastics tailored to performance and budget requirements.

Advanced laser cutting ensures consistent part quality and tight tolerances for both metals and plastics.

Tailored designs and material combinations maximize functionality across applications.

Continuous monitoring of laser cutting to detect deviations immediately. Minimizes defects and ensures consistent quality throughout production.

Establishes export-ready workflows adhering to international standards. Guarantees repeatability and compliance across all batches.

Full documentation and traceability of inspection results. Enables swift identification of issues and supports quality audits and certifications.

Advanced imaging detects surface defects and dimensional errors instantly. Reduces manual inspection effort and boosts production efficiency.

Leveraging quality data trends to refine cutting parameters continuously. Enhances yield and reduces material waste across export processes.

Integrated dashboards provide oversight of all export standard process steps. Ensures adherence to quality checkpoints from start to finish.

Understanding each industry‘s unique requirements ensures optimized laser cutting solutions.

High-precision laser cutting ensures flawless components for sensitive electronics.

Durable, accurate metal parts manufactured to strict tolerances for vehicle assembly.

Lightweight, complex components optimized for high performance and safety standards.

Custom decorative panels and structural elements with precise, clean edges.

Reliable stainless steel parts tailored for heavy-duty applications and durability.

Precise, clean laser cuts optimize performance and reliability in critical medical parts.