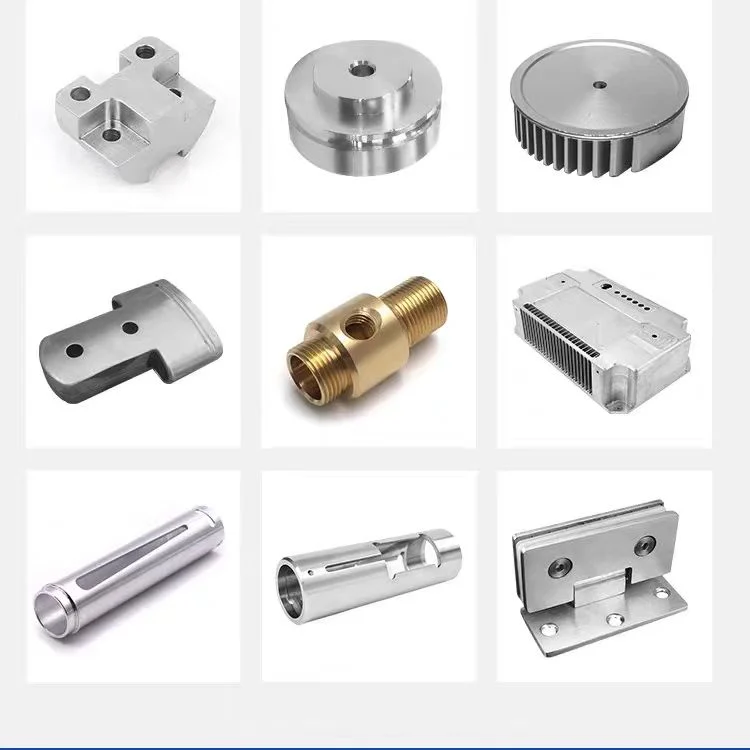

Precision CNC Turned Parts

High-accuracy CNC turned components optimized for automotive, aerospace, and industrial machinery.

ZSCNC delivers high-quality precision CNC turning solutions tailored to your manufacturing needs. Experience superior accuracy, fast turnaround, and competitive pricing. Discover our full range of CNC machining services designed to meet diverse industrial requirements.

High-accuracy CNC turned components optimized for automotive, aerospace, and industrial machinery.

Intricate milled parts designed for electronics, medical devices, and precision instruments.

Durable stainless steel shafts for home appliance motors and miniature mechanical applications.

At ZSCNC, we specialize in delivering a wide range of precision CNC components matched to your industry needs. Our parts support applications from heavy industrial machinery to delicate electronics, ensuring reliability and exact fit. To learn more about our company, visit our About Us page. Trust our expertise for tailored manufacturing solutions that drive efficiency and product excellence.

Custom CNC machining of plastic parts for automation medical and packaging with ISO 9001 precision fast turnaround and engineering plastics

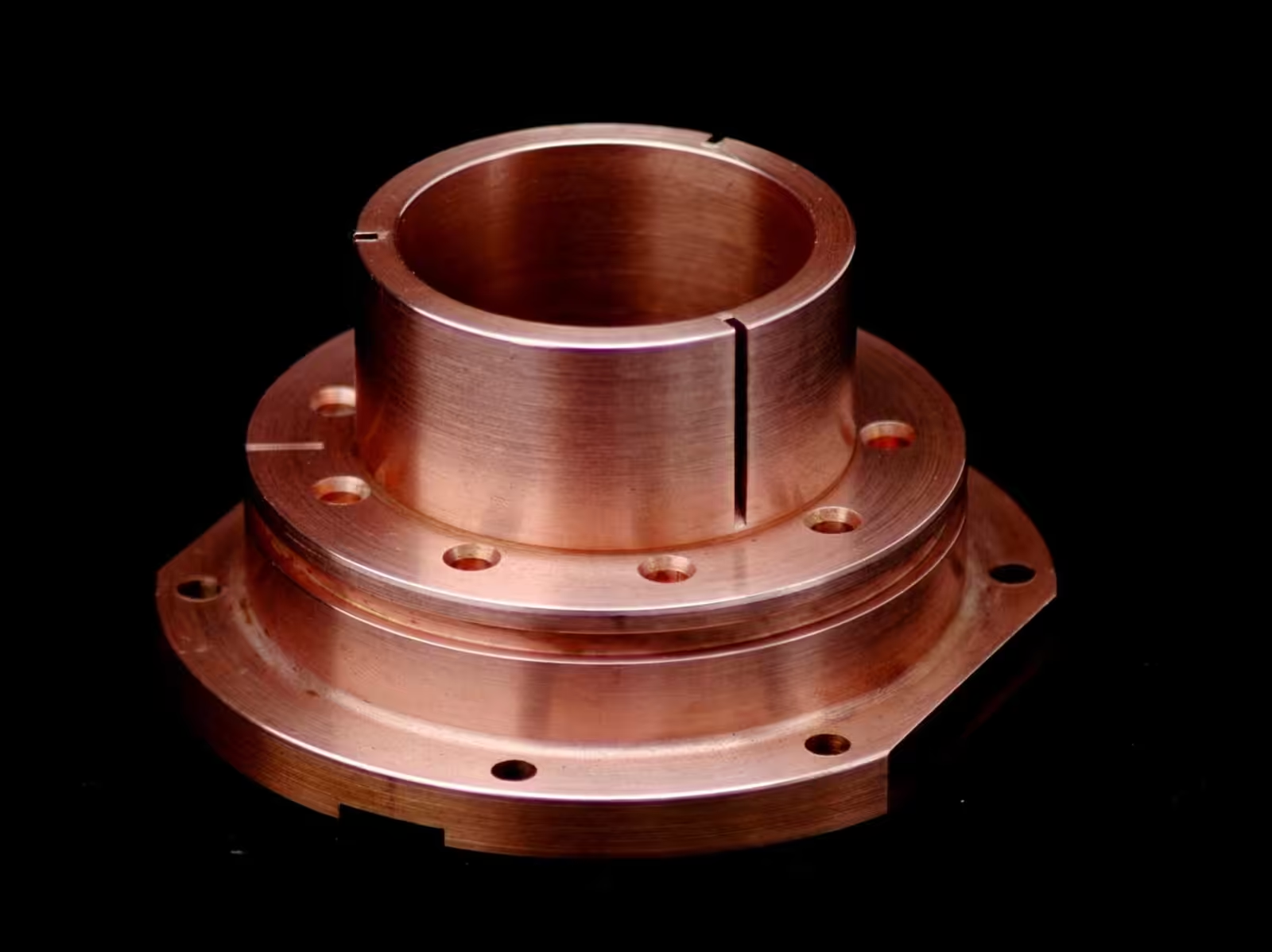

Factory direct custom CNC machining of brass copper and conductive components with tight tolerances plating and rapid prototyping

Precision CNC machining services for EU automotive components and motorsport parts with tight tolerances ISO certification and fast delivery.

Precision CNC machining services for food and packaging equipment with FDA-compliant materials rapid delivery and sanitary finishes

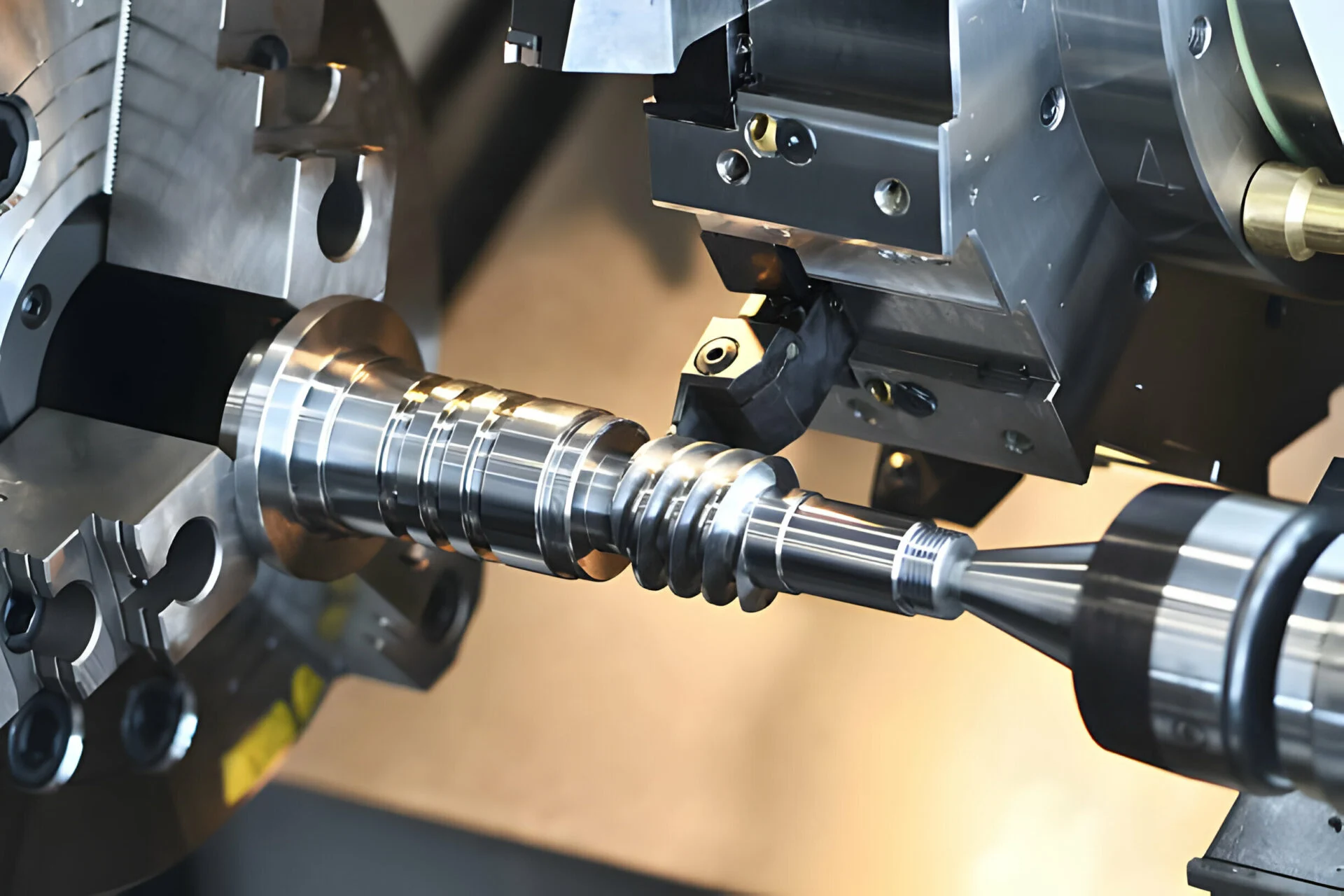

ZSCNC delivers precision CNC turning with tight tolerances and extensive dimensional ranges. Our expert machining optimizes efficiency while ensuring consistent quality.

ZSCNC expertly processes a wide range of materials including steel, stainless steel, aluminum, and specialty alloys. This ensures parts meet stringent mechanical and durability requirements.

Our advanced surface inspection and finishing technology tightly controls roughness, texture, and tolerance to guarantee optimal performance and longevity.

Using state-of-the-art CNC turning and inspection tools, we deliver consistent surface finishes and dimensional accuracy across high volume production runs.

ZSCNC specializes in machining intricate geometries with precision and repeatability. Our multi-axis turning systems deliver complex components that meet exacting standards.

Our multi stage turning solutions enhance efficiency while maintaining superior dimensional accuracy across multiple operations without repositioning.

Utilizing precision tooling and advanced CNC controls, we achieve fine surface finishes, reducing downstream processing and improving product lifespan.

We apply advanced measuring equipment to verify component dimensions, ensuring adherence to strict tolerances.

Using visual and microscopic assessments, ZSCNC confirms surface integrity to prevent defects and improve durability.

Real-time monitoring during turning operations helps identify anomalies early, maintaining consistent product quality.

Finished components undergo performance testing simulating real-world conditions to guarantee reliability.

At ZSCNC, we ensure seamless order coordination through real-time tracking and transparent communication. Our process aligns client requirements with production capabilities, minimizing delays. Learn more about our company.

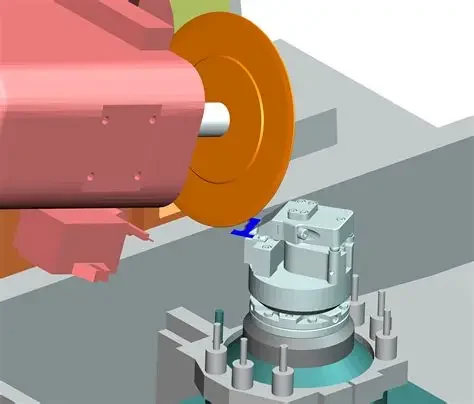

Our advanced CNC turning technologies deliver precise prototype samples. We emphasize tight tolerances and thorough inspections to guarantee quality before mass production.

From order initiation to prototype approval, our well-defined workflow ensures each step aligns with customer expectations, driving efficiency and reducing rework.