Metals & Plastics Classification Matrix

Metals Classification Framework

Our metals classification system organizes alloys by core properties, enabling precise material selection for high-performance applications. For specialized needs, explore our sheet metal fabrication services and detailed metal materials catalog.

- Structural metals: Steel, aluminum, titanium variants

- Corrosion-resistant alloys for harsh environments

- Thermal & electrical conductivity ratings

- Manufacturing process compatibility

Plastics Classification Matrix

The plastics classification matrix groups polymers by mechanical and thermal properties to match application-specific needs efficiently.

- Engineering plastics: PEEK, Nylon, POM with enhanced durability

- Thermoplastics vs thermosets application direction

- CNC machinability and surface finish considerations

- Environmental resistance and chemical compatibility

Core Selection Dimensions & Application Directions

Mechanical Properties

Strength, hardness, and elasticity requirements tailored to your project.

Thermal Performance

Heat resistance and conductivity metrics for reliable operation.

Manufacturability

Compatibility with CNC and other advanced fabrication methods, including metal stamping.

Application Environment

Chemical exposure and environmental durability factors considered.

Metal Material CNC Machining Services

Metal Material Service Positioning

At ZSCNC, we specialize in precision metal machining services tailored to diverse industrial needs. Our expert processes ensure high-quality components that meet strict standards in strength and durability.

Typical Metal Material Categories

- Carbon Steel – versatile and cost-effective with excellent machinability

- Stainless Steel – corrosion-resistant for demanding environments

- Aluminum Alloys – lightweight with good strength-to-weight ratio

- Brass and Copper – excellent electrical conductivity and corrosion resistance

- Titanium – high strength and corrosion resistance for aerospace applications

Applicable Scenarios

Our metal materials serve applications across automotive, aerospace, medical devices, electronics, and industrial machinery. We deliver parts optimized for performance, reliability, and extended service life.

Processing Traits

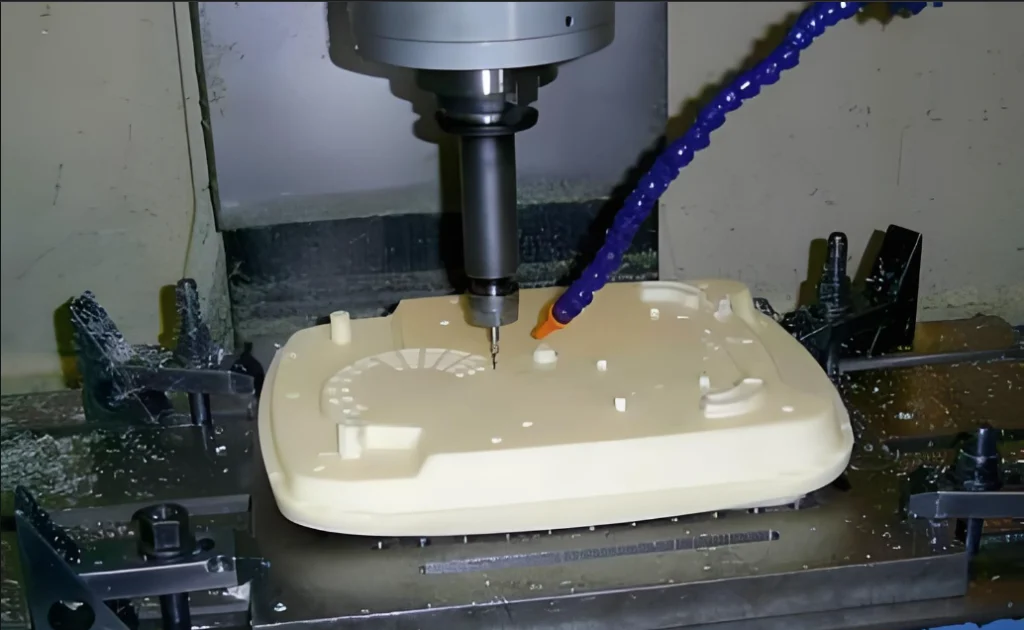

ZSCNC leverages CNC machining services including milling, turning, and grinding to achieve precise tolerances. Our processes minimize residual stress and ensure consistent surface finish quality for each metal type.

Plastic Material CNC Machining Services

Service Positioning

ZSCNC offers precision plastic manufacturing services tailored for high-performance applications. Our expertise ensures consistent quality, rapid prototyping, and scalable production that meet your exact specifications.

Typical Plastic Material Categories

- ABS: Durable, impact-resistant, ideal for housings.

- Polycarbonate (PC): High toughness and clarity.

- Polyethylene (PE): Chemical resistant and flexible.

- Polypropylene (PP): Excellent fatigue resistance.

- Acetal (POM): High stiffness and low friction surface.

- Nylon (PA): Strong and resilient under stress.

Plastic Processing & Assembly Highlights

Utilizing advanced CNC machining services, injection molding, and precision assembly, ZSCNC delivers complex plastic components with tight tolerances. Our integrated processes optimize durability and performance for critical applications.

- High-precision CNC machining with tight dimensional control

- Custom secondary operations including bonding, ultrasonic welding, and insert molding

- In-house quality inspection ensures superior surface finish and structural integrity

- Flexible batch sizes supporting prototypes through volume production

Material Performance Selection Reference

Understanding key performance parameters ensures optimal material choices for your projects. Focus on measurable industry criteria to improve product quality and communication.

Key Performance Parameters

- Strength and durability under operational conditions

- Thermal and chemical resistance

- Surface finish quality requirements

- Dimensional stability and tolerances

Typical Industry Focus Points

- Aerospace: Weight reduction and fatigue strength

- Automotive: Cost-effective durability and heat resistance

- Medical: Biocompatibility and precision

- Electronics: Electrical insulation and thermal management

Selection Communication Tips

- Use clear parameter definitions with measurable units

- Highlight trade-offs between performance and cost

- Provide examples or case studies

- Ask for vendor clarifications on unknowns

ZSCNC: Precision Material Performance Expertise

At ZSCNC, we assist you in selecting materials based on verified performance metrics. Our experience across industries ensures the best balance of function, cost, and manufacturability.

Utilize our detailed parameters and communication strategies to align suppliers, engineers, and stakeholders for seamless project success.

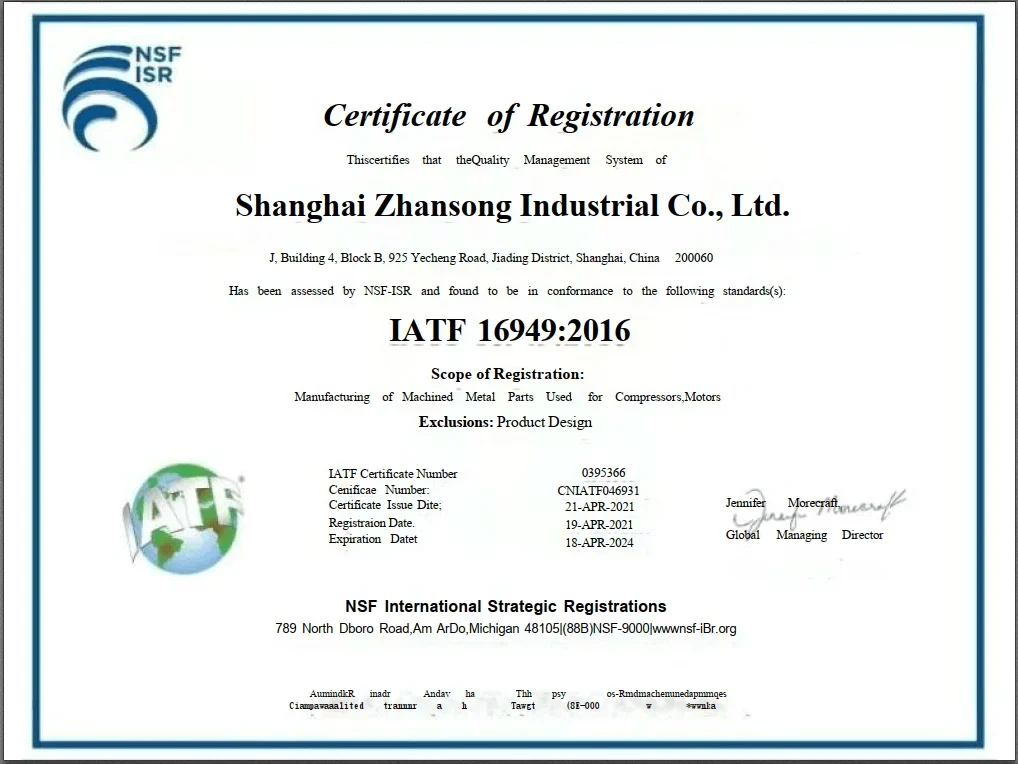

International Standards & Quality Traceability

ZSCNC ensures strict adherence to global material standards and specifications. Our comprehensive material quality inspection and validation processes guarantee compliance with overseas market regulations.

- Detailed material standards specification systems

- Robust quality inspection at every production stage

- Accurate material validation to meet international stainless-steel norms

- Seamless alignment with overseas compliance requirements

Project Level Material Collaboration & Customization

Collaboration Workflow Customization

Tailor collaboration workflows at the project level for seamless communication and coordination. Improve efficiency by aligning team processes with material-specific needs.

Special Material Treatments

Enable advanced customization options for special treatments including surface finishing, coatings, and enhanced durability features. Ensure every component meets specific project demands.

Risk Feasibility Pre-Evaluation

Conduct thorough risk and feasibility analysis before material approval to mitigate project delays and cost overruns. Support informed decisions with data-driven insights.