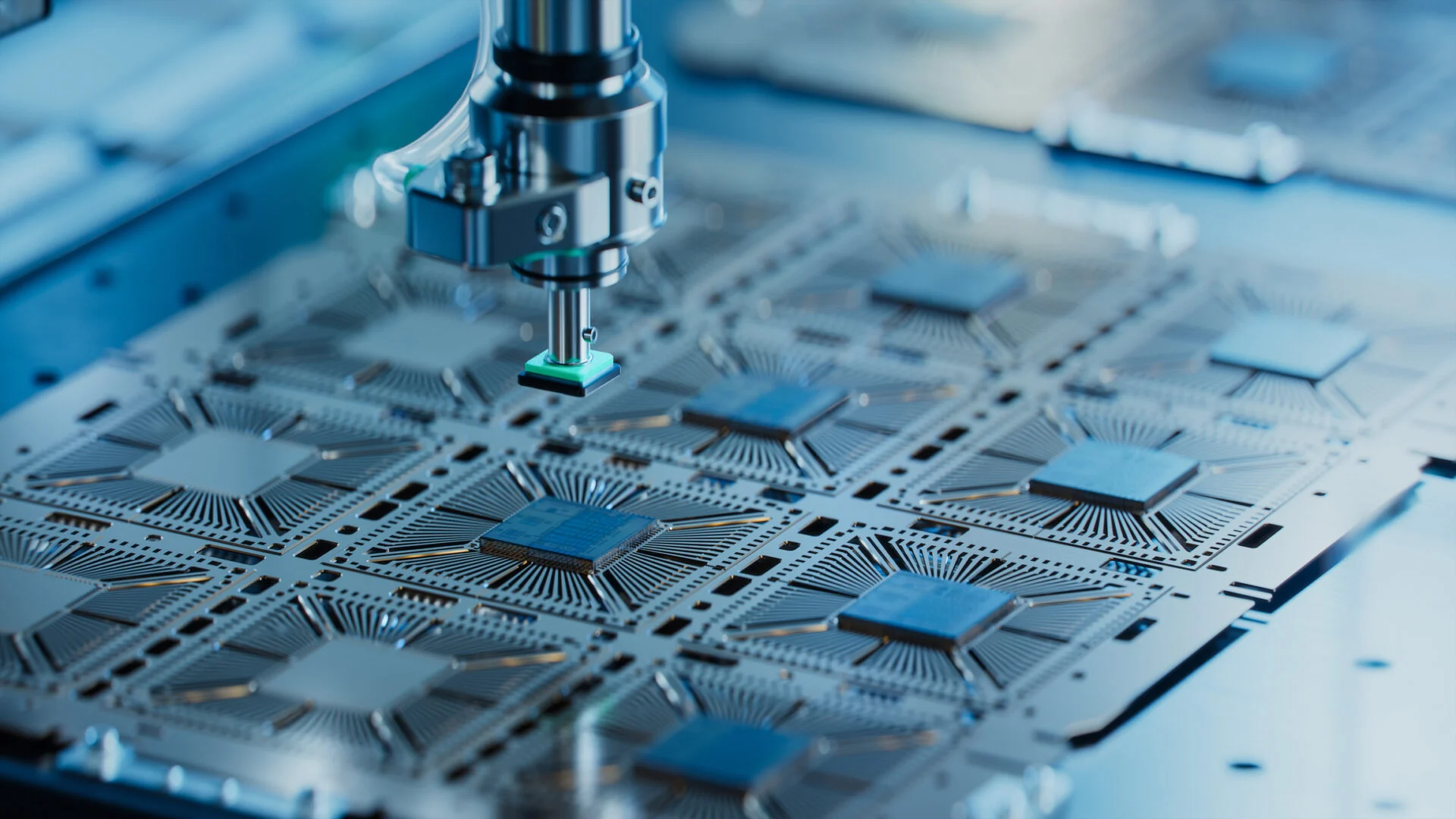

Precision CNC Machining for the Electronics Industry

ZSCNC delivers unrivaled accuracy and reliability in CNC machining for electronic components. Our cutting-edge processes meet strict tolerances to ensure seamless integration and optimal performance.

Trusted partner for high-volume production, prototype development, and complex designs with industry-leading turnaround times.

Precision Electronic Component Housings & Structural Parts

ZSCNC delivers high-quality housings and structural parts engineered for reliability and exact fit. Our advanced manufacturing capabilities ensure components meet stringent industry standards.

- Custom CNC machining for complex geometries with tight tolerances

- Durable materials optimized for electronic protection and structural stability

- Scalable production with rapid prototyping and short lead times

- Surface treatments to enhance corrosion resistance and appearance

Engineering Excellence

Tailored designs optimized through simulation and material selection for maximum durability.

Advanced Manufacturing

State-of-the-art CNC machining and finishing processes to achieve precise dimensions and finishes.

Quality Assurance

Rigorous inspection protocols ensure every component meets or exceeds client specifications.

Precision Connectors & Interface Component Machining

Deliver mission-critical electronics with ZSCNC's ultra-precise CNC machining solutions.

Engineered for Precision, Built for Reliability

ZSCNC specializes in high-tolerance machining of connectors, interfaces, and electronic components.

Our advanced CNC systems maintain tolerances within microns, ensuring seamless integration across industries.

- Sub-micron precision for critical interfaces

- High-volume production with zero deviation

- Materials: aluminum, brass, steel, composites

- Full traceability and quality documentation

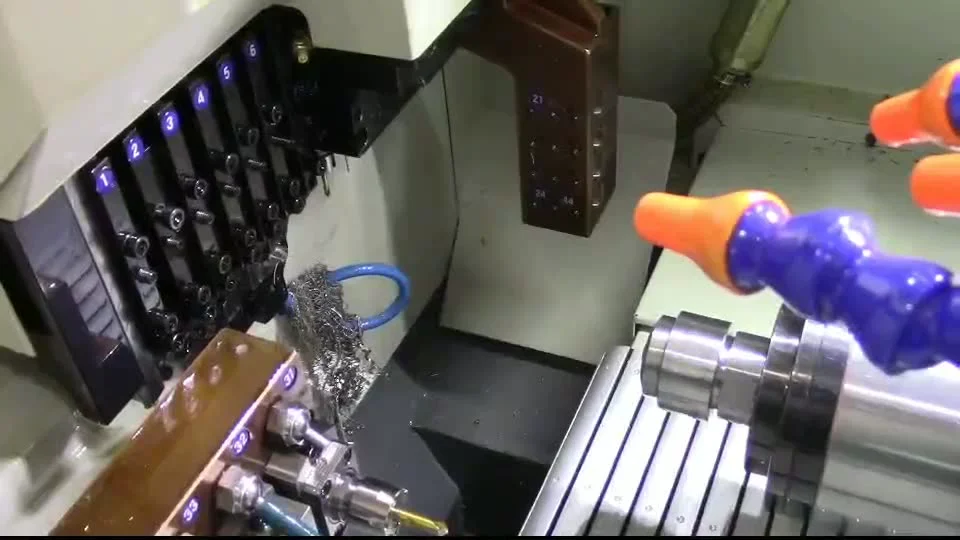

Core Machining Capabilities

Multi-Axis Machining

5-axis simultaneous processing for complex geometries and reduced setup time.

Connector Interface Design

Custom contact pins, housings, and specialized interfaces for electronics integration.

Quality Assurance

Automated inspection, CMM verification, and statistical process control.

Why ZSCNC for Precision Connectors

Advanced CNC Equipment

Our facility operates state-of-the-art multi-axis CNC machining machines with real-time monitoring systems.

Automated tool changers, spindle speeds up to 24,000 RPM, and AI-assisted error detection.

Material Versatility

From soft non-ferrous metals to hard composites, we machine diverse materials.

Expert handling of aluminum, brass, stainless steel, titanium, and advanced polymers.

Rapid Prototyping to Production

Design review, prototype iterations, and seamless transition to full production runs.

Quick-turnaround samples within 48 hours for qualified engineering reviews.

Functional Structural Optimization for Electronic Devices

At ZSCNC, we specialize in optimizing structural designs to enhance the performance and durability of your electronic devices. Our advanced CNC machining processes ensure precision and reliability in every component.

Structural optimization reduces weight, improves thermal management, and maximizes space efficiency without compromising device integrity. This delivers tangible benefits in electronics manufacturing and end-user performance.

Leveraging cutting-edge technology and tailored engineering, ZSCNC’s solutions accelerate product development while minimizing material costs and assembly complexity. Learn more about our about page to understand our expertise.

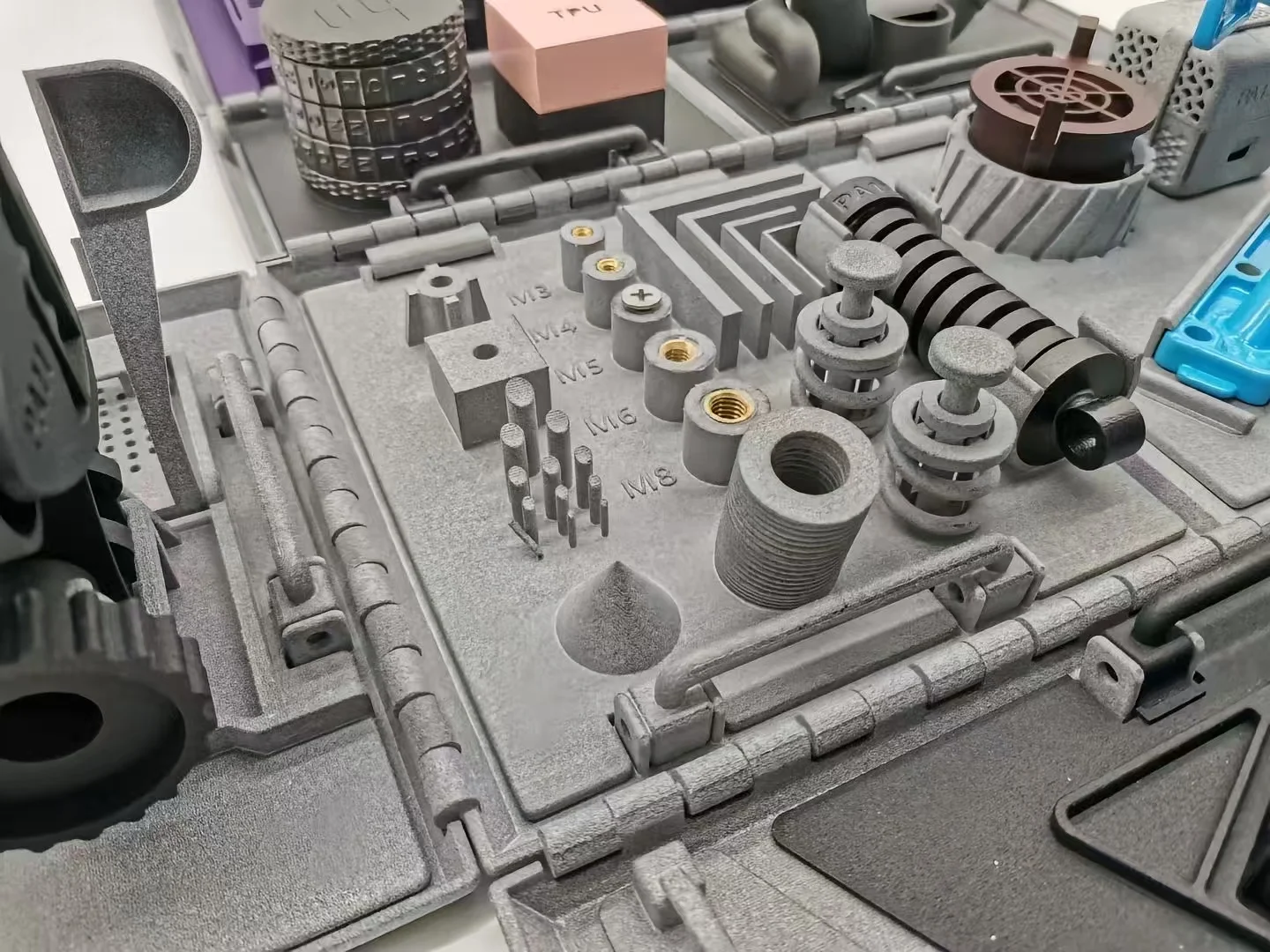

Materials & Process Routes Tailored for Electronic Components

Precision Materials for Optimal Performance

We select advanced materials engineered to meet high durability and conductivity standards for electronic components.

Our expertise in specialized alloys and composites ensures enhanced thermal management and electronic stability.

Tailored Process Routes for Quality Manufacturing

Utilizing state-of-the-art CNC machining and precision molding, our processes are customized to each component's specifications.

Rigorous quality assurance at every stage guarantees consistent, reliable outputs optimized for your applications.

Material Selection

Customized materials such as alloys and composites selected for conductivity, thermal resistance, and mechanical strength.

Process Optimization

Advanced CNC and molding processes tailored to component complexity and production volume.

Quality Assurance

Multi-stage inspection protocols ensure product reliability and compliance with industry standards.

Quality Control & Inspection for Electronic Parts

At ZSCNC, we guarantee uncompromising precision in every electronic component through rigorous quality control processes.

Our advanced inspection technology ensures compliance with industry standards, reducing defects and boosting reliability.

Benefit from improved yield rates, traceability, and timely detection of faults during production.

Visual Inspection

Detect surface defects, solder joint integrity, and component placement with high-resolution imaging tools.

Electrical Testing

Verify functionality and electrical parameters with automated test equipment for consistent performance.

Dimensional Measurement

Precision measurement tools ensure mechanical dimensions meet strict tolerances to guarantee fit and reliability.

Streamlined Electronics Project Collaboration

At ZSCNC, our service model integrates precise CNC machining with a seamless project workflow. We ensure fast delivery, quality control, and clear communication at each step.

1. Project Consultation & Planning

Understand your specifications and timeline to tailor our processes effectively.

2. Precision CNC Manufacturing

Utilizing state-of-the-art machinery for complex electronic components and enclosures, including advanced milling techniques.

3. Dedicated Quality Assurance

Rigorous inspection to ensure every part meets industry standards.

4. Timely Delivery & Support

Efficient logistics combined with ongoing project updates to keep you informed.