Comprehensive Inspection Procedures

Our quality control process ensures every machined part meets strict tolerances through multiple inspection stages.

ZSCNC delivers comprehensive CNC milling machining solutions tailored to

exacting standards. Our matrix integrates multi-axis precision, rapid

prototyping, and volume production, streamlining your manufacturing

process.

Utilizing advanced technology, we guarantee exceptional tolerance control

and consistent quality across metals, plastics, and composites.

Experience unmatched accuracy and reliability for your critical

components.

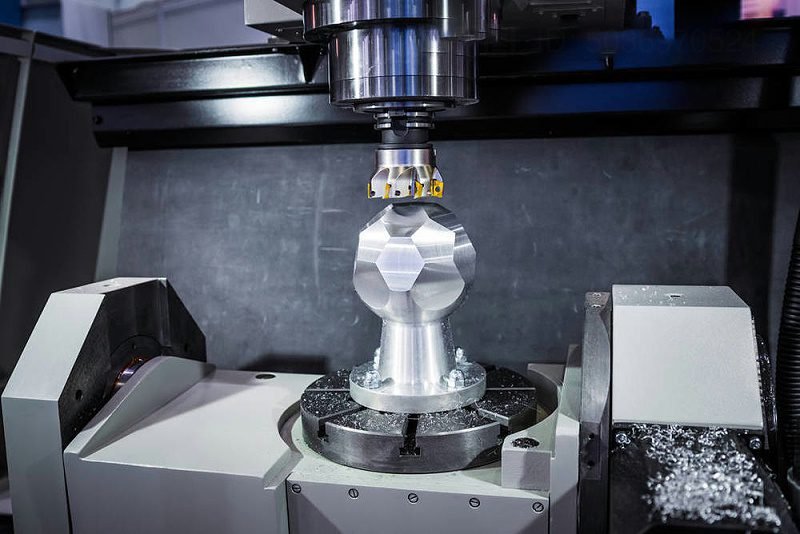

Complex geometries with 3, 4, and 5-axis CNC setups increase precision and reduce cycle times.

Achieve ±0.005mm accuracy ensuring parts fit and function perfectly in every assembly.

Expertise in machining metals, plastics, and composites tailored to your design needs.

Fast turnaround on prototypes accelerates product development timelines without compromising quality.

Custom CNC machining of plastic parts for automation medical and packaging with ISO 9001 precision fast turnaround and engineering plastics

Precision CNC machining services for EU industrial machinery and equipment manufacturers with ISO 9001 quality tight tolerances and DDP shipping

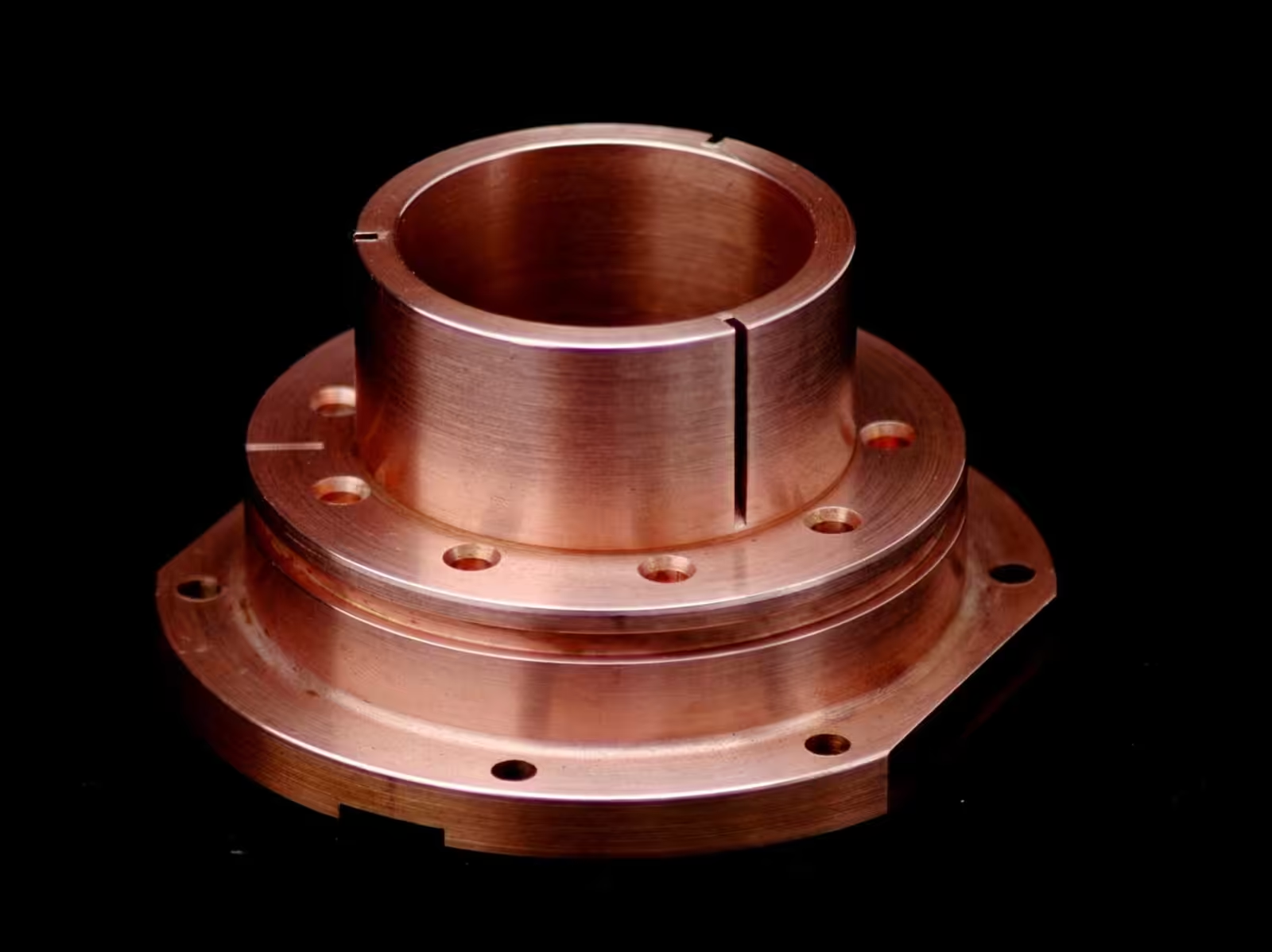

Factory direct custom CNC machining of brass copper and conductive components with tight tolerances plating and rapid prototyping

Precision CNC machining services for EU automotive components and motorsport parts with tight tolerances ISO certification and fast delivery.

ZSCNC offers a full range of CNC machining services including milling, turning, drilling, and grinding. Our capabilities cover prototype to high-volume production.

We achieve tight tolerances down to ±0.001 inches with advanced quality controls. Critical dimension inspections ensure unmatched reliability for complex parts.

ZSCNC delivers aerospace parts with tight tolerances and superior surface finishes to meet critical safety standards.

Our CNC machining efficiently produces automotive components with complex geometries and consistent repeatability.

High-tolerance metal and plastic parts for medical instruments, ensuring biocompatibility and regulatory compliance.

Durable parts engineered for industrial machinery with optimal precision and wear resistance.

Advanced 5-axis machining enables production of parts with intricate shapes and tight dimensional control.

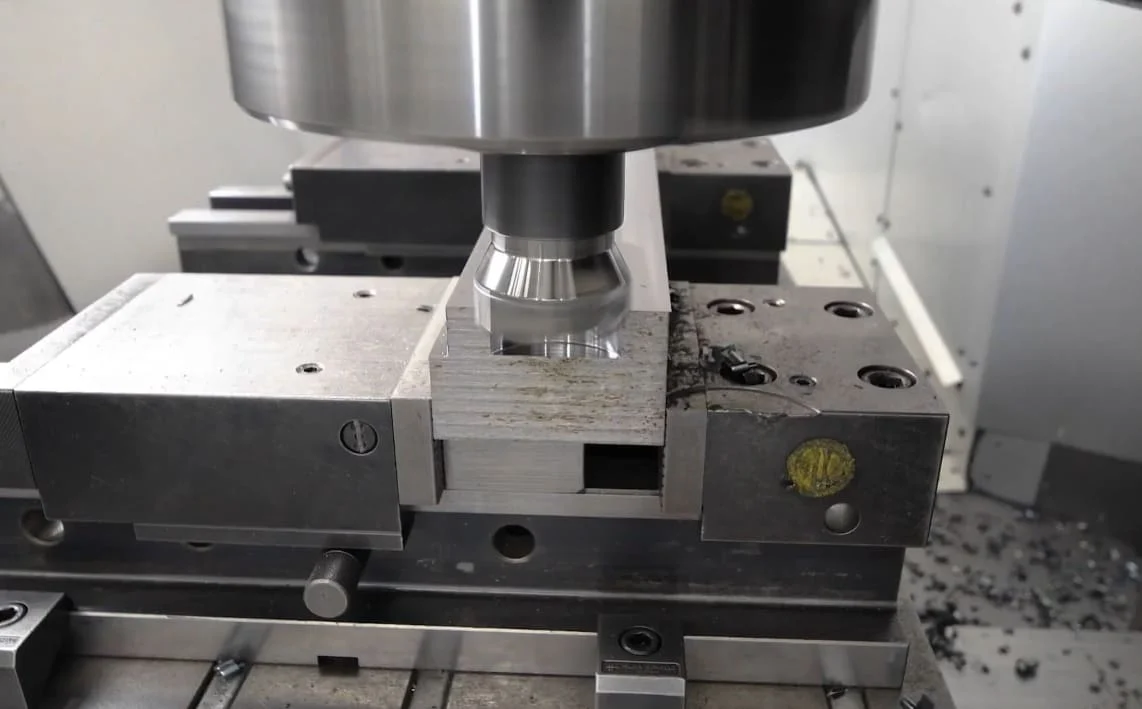

Expert milling on metal and plastic parts achieves smooth finishes and exact dimension control.

Our quality control process ensures every machined part meets strict tolerances through multiple inspection stages.

We utilize state-of-the-art CNC measuring machines and optical inspection systems for precise dimensional accuracy.

Material properties are verified before production to guarantee full compliance with client specifications.

Every inspection step is fully documented, providing traceability and confidence in our manufacturing process and product quality for our clients.

ZSCNC utilizes cutting-edge

products with CNC machining technology, ensuring consistent high precision and tight tolerances. Our production line adapts to diverse project requirements efficiently.

From prototype runs to large-scale manufacturing, ZSCNC scales operations seamlessly while maintaining quality. Our streamlined workflows reduce downtime and enhance throughput.

We prioritize on-time delivery using an integrated logistics system. Transparency in order tracking and inventory control ensures customers receive products on schedule without compromise.

Our experts work closely with you to understand your unique engineering needs and specifications accurately.

We create tailored designs and rapid prototypes ensuring feasibility and precision before moving to production.

Utilizing state-of-the-art CNC milling service, we guarantee high tolerance and consistent quality throughout production.

Comprehensive after-sales support and timely delivery ensure your project meets deadlines and performance expectations.

ZSCNC delivers precision CNC machining services to diverse industries across the United States. Our expertise powers automotive, aerospace, medical, and industrial clients with unmatched reliability and quality. Learn more about our company on the about page or contact us for inquiries.

Delivering high-tolerance parts that optimize vehicle performance and safety.

Precision machining for critical aerospace components with stringent quality standards.

High-precision parts supporting innovative and reliable medical solutions.

Durable and precise components tailored to rigorous industrial requirements.

State-of-the-art 5-axis CNC machining delivering complex geometry parts efficiently.

Tailored manufacturing to meet unique client specifications with precision and speed.