Brass Precision Machining Materials Overview

ZSCNC delivers unmatched brass CNC machining services with superior precision and quality. We specialize in complex brass components designed for optimal durability and performance.

Material Properties of Brass material

Mechanical Performance Highlights

Brass offers excellent machinability, tensile strength, and wear resistance for durable applications.

Electrical and Thermal Performance

High electrical conductivity and thermal stability make brass ideal for connectors and switches.

Dimensional and Surface Stability

Brass maintains dimensional accuracy with low surface oxidation for long-term reliability.

Application

Widely used in electrical, plumbing, and decorative industries due to its versatile performance.

Brass Grades and Size Capabilities for Machining

Typical Brass Grade Categories

- Free-machining alloys: high machinability for complex parts

- High-strength alloys: optimized for mechanical performance

- Wear-resistant grades: durable for harsh environments

- Corrosion-resistant brass for electrical applications

- Lead-free and environmentally compliant options

Available Stock Forms

ZSCNC offers brass in various stock forms to meet machining needs:

- Rounds, rods, and bars in multiple diameters

- Sheets and plates with consistent thickness

- Tube and pipe options for specialty fittings

- Custom cut-to-size lengths for streamlined production

Size and Tolerance Capabilities Overview

Diameter Range

From 0.1 inches to 6 inches diameter stock available

Tolerance Levels

Standard ±0.005", precision down to ±0.0005" on request

Surface Finish

Up to 16 micro-inches Ra achievable for critical parts

Engineering Communication Tips

Clear specification on grade, size, tolerance, and finish reduces rework. Include detailed drawings and reference standards.

Early collaboration with ZSCNC engineers helps optimize designs and machining strategies for cost-effective manufacturing.

Brass Precision CNC Machining Capabilities

Turning and Milling Proficiency

At ZSCNC, we specialize in precision turning and milling of brass components, ensuring tight tolerances and superior surface finishes for complex geometries.

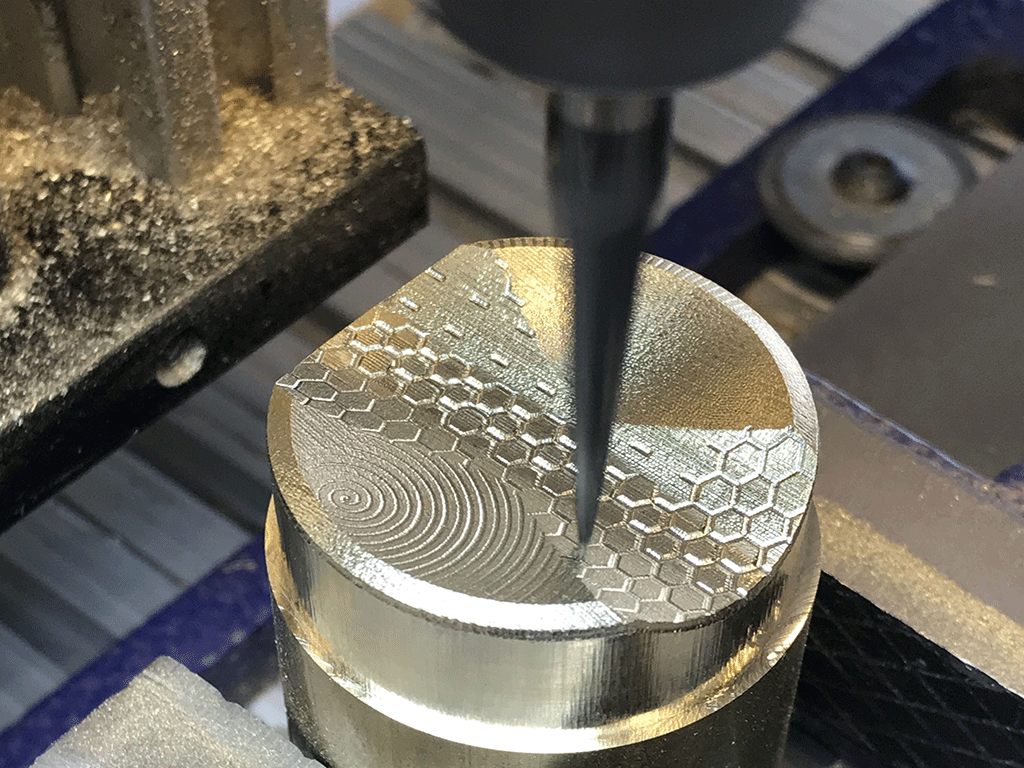

Fine Detail Machining

Our advanced CNC machines achieve exceptional detail on brass parts, ideal for intricate designs and components where precision is critical.

Process Control and Efficiency

We maintain rigorous process controls to streamline production while maximizing efficiency, reducing lead times and ensuring consistent quality.

Typical Process Combinations for Brass

Turning + Milling

Combined multi-axis operations for complex shapes and fine surfaces.

CNC Drilling + Tapping

Precision hole-making and threading for assembly ready parts.

Micro-Machining

High-accuracy, small-feature machining for detailed components.

Surface Finishing

Polishing and deburring processes for functional and aesthetic quality.

Multi-Stage Machining

Sequential operations to optimize precision and process flow.

Inspection & Quality Control

On-site measurement systems ensure consistent accuracy and compliance.

Surface Quality and Post Processing Options for Brass Parts

Base Surface Quality

Brass parts typically feature a fine surface from CNC milling or turning. Surface roughness ranges from 0.8 to 3.2 micrometers Ra, depending on tooling and process settings. To ensure consistent quality control, thorough inspection is essential.

Common Post Processing Methods

- Polishing to enhance luster and reduce oxidation.

- Buffing and tumbling for smooth, uniform finishes.

- Plating or coating for corrosion resistance.

- Heat treatments to improve hardness and durability.

Engineering Considerations

Selecting appropriate surface finishes impacts functionality, wear resistance, and longevity. Discuss processing needs early to optimize manufacturability and cost.

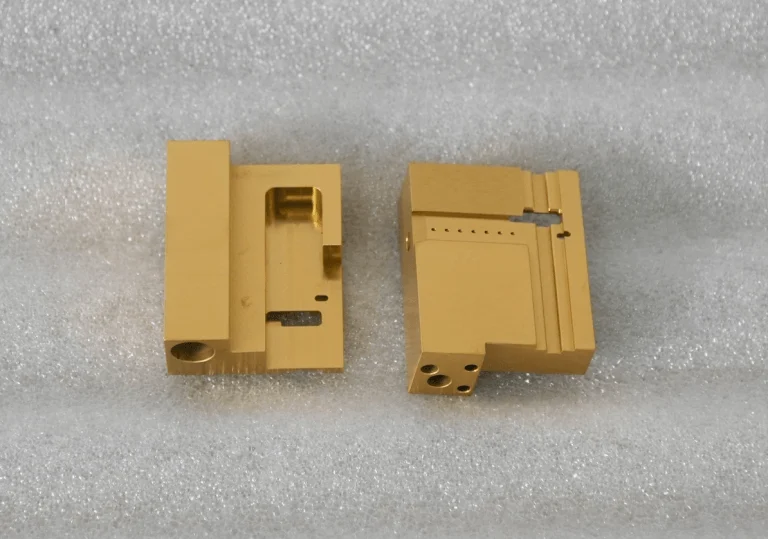

Precision Brass Components

High tolerance brass parts with consistent surface finishes tailored to exact engineering specifications.

Advanced CNC Machining

Utilizing advanced CNC technology to deliver superior surface quality and dimensional accuracy.

Durability & Finish Optimization

Engineering optimized finishes tailored to the brass alloy’s wear resistance and environmental exposure.

Brass Applications & Component Types

Electrical Connection & Signal Transmission

High-precision brass components ensure reliable electrical connections and accurate signal transmission in demanding industrial environments.

Control & Instrument Components

Durable brass parts designed for precise control instruments improve performance and longevity in sensitive equipment.

Mechanical & Structural Small Components

Precision-machined brass parts provide structural integrity and wear resistance in mechanical assemblies.

Customer Guidance

ZSCNC offers expert support to select and customize brass components tailored to your exact technical and quality requirements. Learn more about our customer service to ensure your needs are met.

ZSCNC: Quality Control and Global Supply Excellence

Process Monitoring and Inspection

Rigorous real-time monitoring and thorough inspections ensure consistent product quality control and defect prevention.

Stable Supply Capacity

Reliable production throughput with scalable capacity enables uninterrupted supply chain fulfillment worldwide.

Global Client Experience

Proven success supporting diverse international clients with tailored manufacturing solutions and compliance.

Collaboration Model

Transparent partnerships enable agile communication, continuous improvement, and shared success.

International Supply Capabilities

Efficient global logistics and compliance frameworks guarantee timely delivery across markets, supported by a robust manufacturing process.