High Performance Machining Solutions for the Automotive Industry

Deliver precision, efficiency, and scalability with ZSCNC’s advanced machining technology. Drive automotive manufacturing excellence with our trusted expertise.

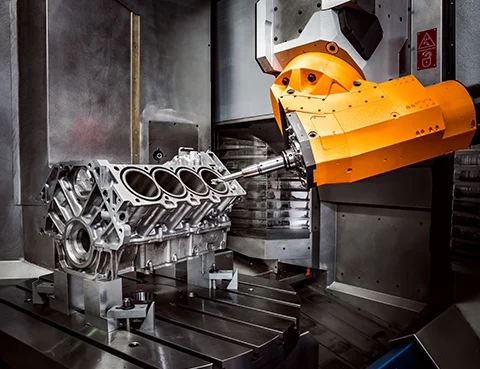

Core Automotive Components Processed by ZSCNC

Powertrain and Transmission Components

ZSCNC delivers precision CNC machining for critical powertrain parts, ensuring durability and optimal performance under extreme conditions.

Chassis and Suspension Structural Parts

Our expertise covers structural chassis components with tight tolerances, providing strength and stability for vehicle safety and comfort.

Body and Interior Functional Hardware

We manufacture high-quality body fittings and interior hardware through advanced milling, combining functionality with aesthetic precision to enhance vehicle value.

New Energy and Electronic Control Components

ZSCNC supports advanced new energy vehicle systems by producing electronic control and high-tech components with exacting standards for reliability, including turning services.

Automotive Materials Expertise & Performance Matching

At ZSCNC, we specialize in precision automotive materials engineered to meet exact performance demands. Our expertise ensures optimal durability, weight reduction, and cost efficiency for your projects.

Precision Material Selection

Our material engineers analyze application parameters to select alloys and composites that deliver superior strength and thermal stability.

Performance Matching & Validation

Using advanced simulation and testing, we align material properties with your vehicle’s performance requirements for reliable results.

End-to-End Support for OEMs

From prototype development to high-volume manufacturing, ZSCNC provides consistent quality and expert consultation throughout your supply chain.

ZSCNC's Advanced Processing Capabilities for Automotive Projects

Precision CNC Turning and Milling

Expert CNC turning and milling ensure tight tolerances for critical automotive components with consistent quality.

Compound and Multi-Operation Machining

Our multi-operation machining capabilities reduce setup times and improve dimensional accuracy across complex parts.

Small Batch Prototyping and Design Validation

Rapid prototyping supports design validation and iteration, accelerating automotive project development cycles.

Quality Control and Dimensional Inspection

Comprehensive inspection processes ensure every part meets dimensional specifications and functional requirements.

Automotive Collaboration Models & Customer Scenarios

OEMs and Platform R&D Teams

Collaborate early with R&D to integrate precision CNC machining, ensuring quality and scalability.

ZSCNC supports seamless communication and iterative prototyping tailored for OEM innovation cycles.

Tier 1 and Tier 2 Suppliers

Enable just-in-time manufacturing with real-time process tracking and precision component delivery.

ZSCNC integrates supplier workflows to optimize quality control and reduce lead times across tiers.

Aftermarket and Racing Teams

Deliver highly customized, performance-driven parts with rapid turnaround and durable materials.

ZSCNC empowers innovation for racers and modifiers through flexible order volumes and expert support.

Automotive Electronics & New Energy Startups

Support rapid scaling with advanced R&D collaboration on electronics and sustainable energy components.

ZSCNC delivers precision, speed, and quality that startups demand for disruptive automotive technologies.

Automotive Grade Quality Assurance & Delivery Excellence

End to End Quality Control

We ensure comprehensive quality control at every stage from raw materials to final assembly, meeting strict automotive standards.

Process Documentation & Production Records

Accurate documentation and traceable production records guarantee transparency and compliance throughout manufacturing process.

Packaging & International Shipping Expertise

Specialized packaging solutions protect parts during transit, backed by proven expertise in global logistics and customs procedures.

Delivery Scheduling & Batch Management

We optimize delivery timelines with meticulous batch management to ensure just-in-time availability and reduce downtime.

Streamlined Collaboration for Automotive Projects

Project Requirements & Drawing Review

Collaborate efficiently to clarify specifications and verify technical drawings for accuracy before production.

Quotation & Process Plan Confirmation

Confirm competitive quotations and detailed process plans to ensure transparent costs and efficient workflows.

Sample Production & Dimensional Validation

Produce prototypes and conduct precise dimensional checks to guarantee quality and fit before full-scale production.

Scale Up to Stable Production

Transition smoothly into volume manufacturing with consistent quality controls, meeting delivery timelines reliably.