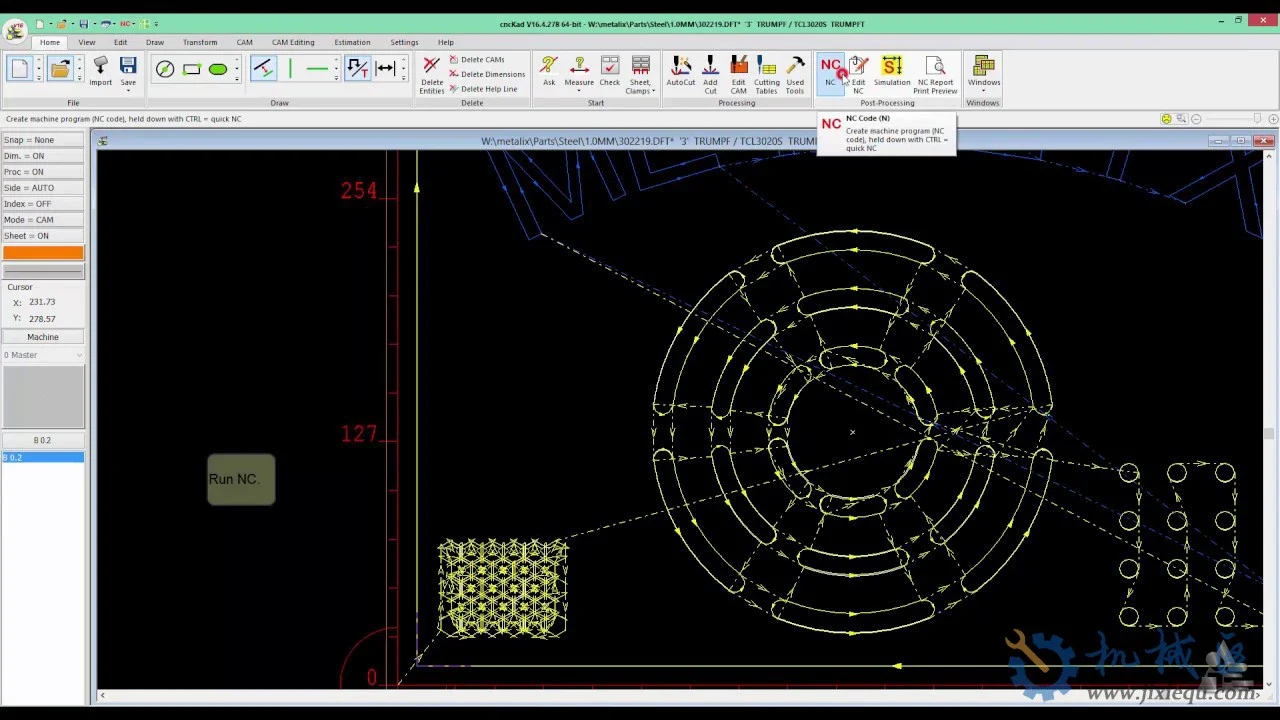

Step 1: Design with CAD

Create precise cutting paths using advanced CAD software. Digital designs optimize material use and accuracy.

ZSCNC offers precision waterjet cutting services, delivering clean, cold cuts for various materials without heat-affected zones.

Achieve tight tolerances and intricate designs on metals, composites, and more. Optimize your manufacturing process today.

Discover how our waterjet cutting services deliver unmatched precision, efficiency, and versatility within fabrication. Experience reduced thermal distortion, superior edge quality, and cutting solutions for diverse materials at ZSCNC.

Our waterjet technology cuts without heat, preventing warping and material stress common in thermal cutting methods.

From metals and composites to glass and stone, our waterjet machines precisely handle a wide range of fabrication materials.

Achieve smooth edges that reduce secondary finishing, saving time and costs while maintaining superior surface quality.

Precision CNC aluminum machining for high performance parts in Europe with ISO certified quality 5 axis capability fast delivery and tight tolerances

Aluminum CNC machining parts supplier for Netherlands and Belgium offering ISO certified precision 6061 7075 components fast EU delivery

Custom CNC machining services for machinery and robotics parts with tight tolerances fast lead times and ISO certified quality

China custom CNC machining supplier for overseas buyers offering ISO certified precision parts fast quotes low MOQ DDPFOB shipping

Metals such as steel, aluminum, and copper are central to industrial applications. Typical thickness ranges vary from 0.5 mm for sheet metal to over 50 mm for structural beams.

Thickness selection impacts strength, durability, and machining methods. ZSCNC ensures precise cutting for consistent quality across all metal thicknesses.

Non-metal materials such as plastics, composites, and glass have distinct thickness ranges and cutting requirements. Precision tailoring improves performance and application suitability.

Common thicknesses range from thin films below 1 mm to structural panels up to 50 mm. ZSCNC employs advanced waterjet and laser cutting for clean, burr-free edges.

At ZSCNC, we ensure exceptional dimensional accuracy and superior edge finish management. Our advanced

systems deliver precise cuts that meet stringent tolerance standards, reflecting our commitment to

quality control.

Achieve exact measurements with minimal deviation to meet strict manufacturing requirements.

Maintain clean, burr-free edges that improve part performance and ease assembly processes.

Continuous monitoring ensures every piece meets ZSCNC’s high standards before delivery.

Create precise cutting paths using advanced CAD software. Digital designs optimize material use and accuracy.

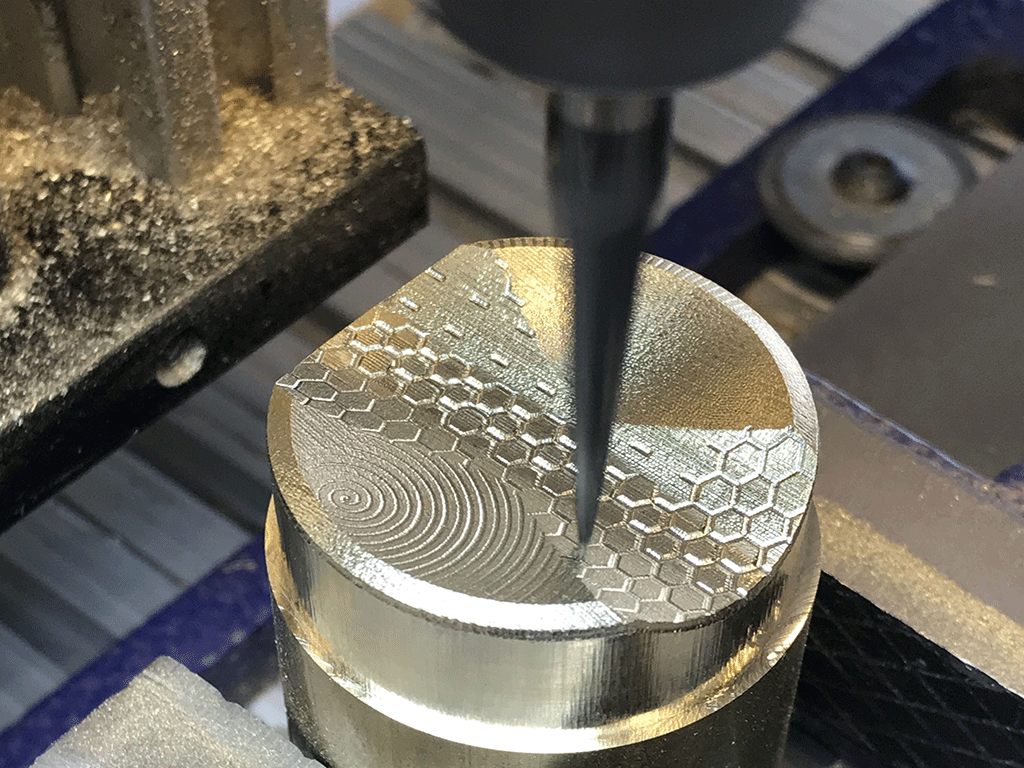

Import CAD files into the waterjet CNC system. Verify cutting parameters for precision and material specifications.

High-pressure water mixed with abrasive materials cuts through metals and composites cleanly, maintaining part integrity.

Thorough inspection ensures exact specifications. Cleaning and finishing processes prepare parts for assembly or shipment.

Trust ZSCNC’s expert workflow to deliver high-quality waterjet cut parts efficiently and accurately.

ZSCNC delivers high-precision tooling solutions that enhance manufacturing accuracy and durability in mechanical parts production. Learn more about our industry manufacturing process.

Our sealing solutions are engineered to meet rigorous standards in automotive, aerospace, and heavy machinery, ensuring optimal component longevity. See our commitment to industry quality control.

Precise cuts without heat, ideal for preserving material integrity in tooling applications.

Enables complex shapes with minimal waste, optimal for sealing solutions needing smooth edges.

Custom tooling designed for exact tolerances, increasing efficiency and part reliability. Discover our company industry profile for more details.

At ZSCNC, we adhere to the highest international quality certifications. Our processes ensure every product meets rigorous durability and safety benchmarks, reflecting our commitment to quality control.

Packaging is tailored to international export regulations. We use eco-friendly, impact-resistant materials to protect shipments during global transit.

Our logistics teams coordinate seamless delivery to worldwide destinations, ensuring on-time arrival and compliance with all customs and safety requirements.

Multi-stage inspections to guarantee product excellence before shipment.

Packaging customized by product type, destination, and handling requirements.

Trusted partners and streamlined logistics for prompt international delivery.