Industrial Equipment Upgrades

Validate rigidity, fit, and assembly order on new frames, drive mechanisms, and mounting elements using metal prototype parts.

Accelerate validation from design concept to functional samples with ZSCNC’s precision CNC machining and mechanical component expertise.

Rapid prototyping powers early-stage product development by producing

small batches of functional prototypes. This enables structural

verification, assembly fit tests, manufacturability pre-assessment, and

design validation. Our

services

also include advanced CNC machining processes to support these stages.

Unlike conventional fabrication, our process offers flexible scheduling,

quick changeovers, and multi-process combinations. It prioritizes

iteration speed and design flexibility — reducing tooling investment and

structural modification costs by using a sample-first approach. For

example,

milling services

help accelerate design iterations with precision.

Custom CNC machining supplier for automotive parts in Netherlands and Belgium offering precision prototypes low volume production and EUgrade quality

Custom CNC machining services for machinery and robotics parts with tight tolerances fast lead times and ISO certified quality

China custom CNC machining supplier for overseas buyers offering ISO certified precision parts fast quotes low MOQ DDPFOB shipping

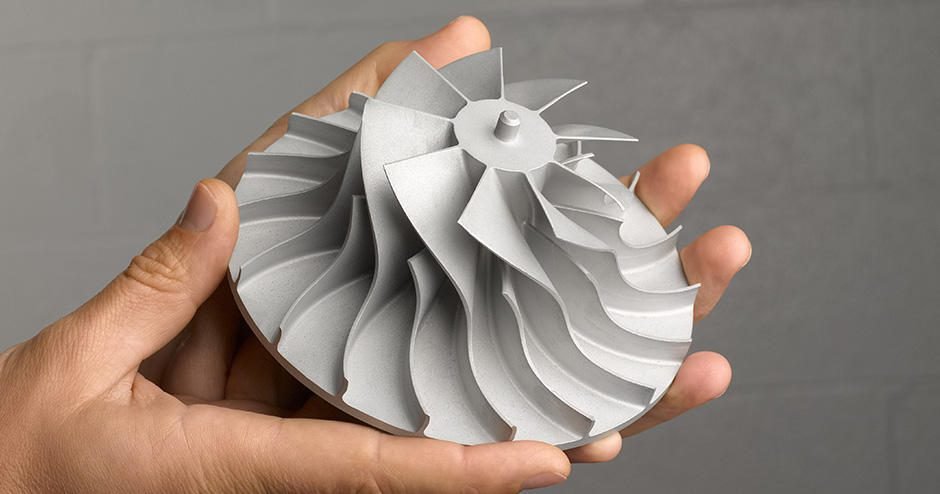

To achieve the required precision, our five-axis CNC machining capabilities support microprecision components through medium-sized structural prototypes with strict tolerance specifications to ensure optimal fit and function. Our quality control ensures every part meets design requirements for assembly and durability.

From Drawing to Finished Prototype

Accept 2D and 3D CAD files with clear functional goals and usage expectations.

Clarify quantity, lead times, and budget to tailor our prototyping approach. Selecting the right materials is crucial at this stage.

Evaluate structural metal materials and processing challenges with risk identification.

Provide design optimization suggestions without compromising your intent.

Offer detailed tiered quotes covering single piece, sampling, batch, and postprocessing options.

Deliver a clear production schedule aligned to client test milestones.

Implement dedicated scheduling with tooling to minimize changeover times.

Conduct in-process inspections on critical dimensions to ensure adherence to specs for titanium materials.

Deliver inspection data summaries for informed client decisions.

Iteratively adjust prototypes or prepare production tooling for follow-up phases.

Validate rigidity, fit, and assembly order on new frames, drive mechanisms, and mounting elements using metal prototype parts.

Perform functional testing on gear holders, connectors, and guide rails with small batch runs. Analyze material wear resistance and cost-effectiveness.

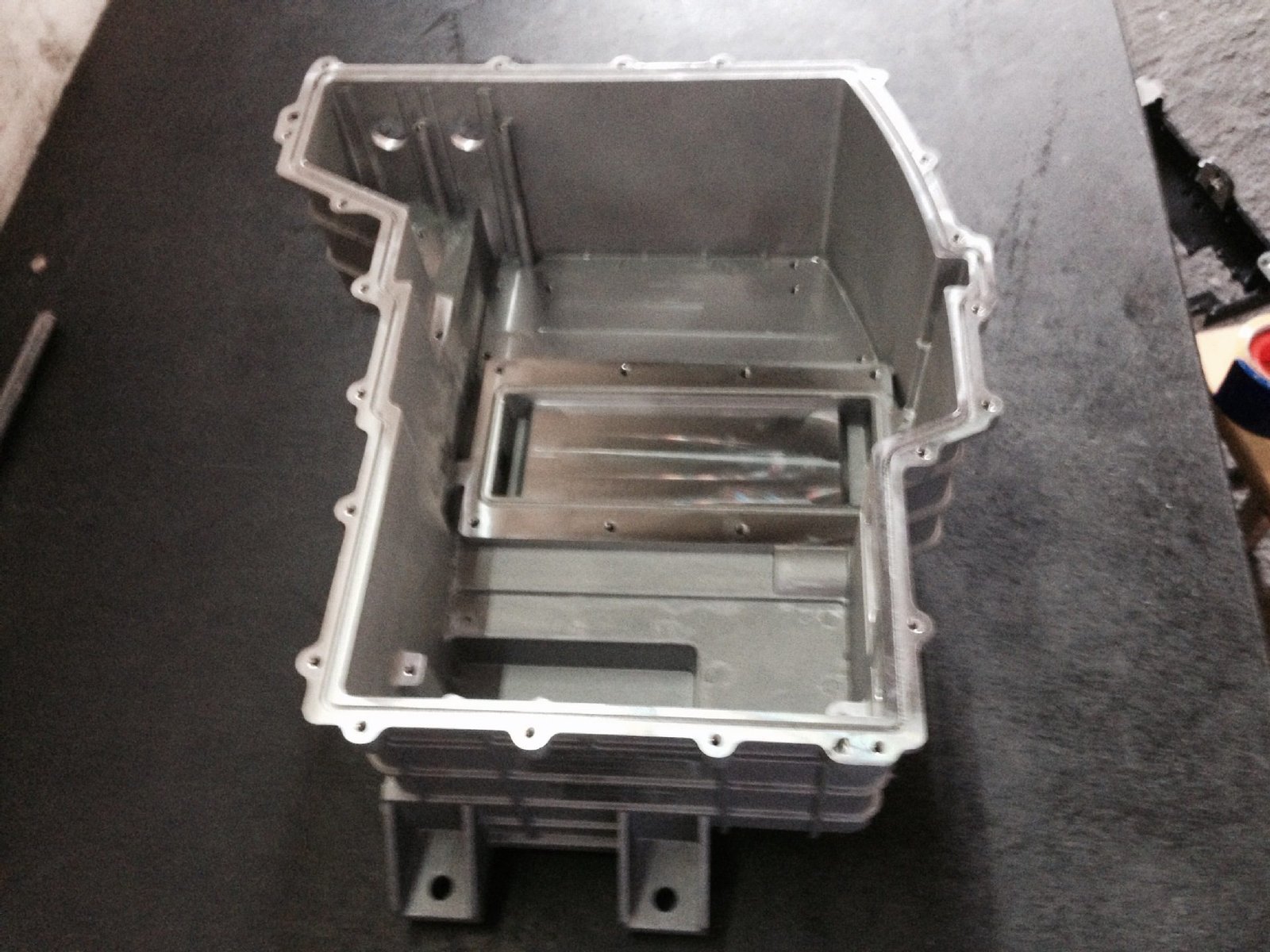

Prototype control boxes, enclosures, and brackets to verify internal layout, heat dissipation, wiring routes, and support onsite assembly trials.

Because diverse markets use different materials, verify unique interfaces, installation methods, and appearance preferences for different markets. Support global distribution and presentations with rapid prototyping.

Critical dimensions and tolerances are verified on assembly and transmission interfaces to ensure seamless fit and function.

Surface finishing includes chamfering, deburring, and edge treatments for operational safety and streamlined assembly.

Material performance is consistently tailored to rigorous testing criteria for reliable prototype behavior, utilizing various materials to meet these standards.

Dimensional inspections match blueprint requirements, ensuring absolute conformance with design specifications.

Trial or simulated assembly tests on critical fit areas verify usability and functional readiness before production.

Adjustable delivery batches align with multiphase structural and functional tests supporting iterative development, especially when working with aluminum materials.

Feedback is integrated promptly for design iterations or mass production readiness, ensuring quality throughout the use of advanced stainless steel materials.

Accelerate innovation through dedicated R&D collaboration, streamlined project management, and seamless scaling from prototype to mass production.

Capture and refine manufacturing parameters during the prototype phase to streamline high-volume production workflows enhanced by CNC milling machining.

Optimize machining turning strategies and production cadence for measurable cost and efficiency improvements.

Refine tool paths and cutting parameters for maximum throughput.

Establish efficient sc