Aluminum Material Characteristics

Lightweight Structural Properties

Low density enables overall weight reduction, ideal for weight-sensitive structural and housing components.

Moderate strength grades balance durability with weight efficiency for diverse industrial uses.

Machining Performance and Dimensional Stability

Low cutting resistance allows efficient machining including milling, drilling, tapping, and turning operations.

Maintains tight dimensional tolerances ensuring precision in critical applications.

Corrosion Resistance and Surface Stability

Natural aluminum oxide film provides baseline corrosion protection in various environments.

Enhanced surface treatments improve weather resistance, durability, and aesthetics.

Thermal Conductivity and Heat Dissipation

Excellent thermal conductivity makes aluminum ideal for heat sinks and cooling bases.

Aluminum Alloy Grades and Performance Spectrum

Common Aluminum Alloy Types

- General Structural Alloys: Ideal for typical components such as brackets and casings.

- Superior Machinability Alloys: Engineered for complex surface finishes and thin-walled parts.

- Balanced Grades: Designed for strength and rigidity in load-bearing but lightweight materials.

Performance Parameter Ranges

Understand approximate tensile and yield strength ranges to estimate load capacity accurately.

Assess hardness and suitability under both static and dynamic loading conditions.

Guidance on Alloy Selection

- Match Material Strength: Align alloy strength with your material structural requirements.

- Consider Machinability: Factor complexity and tolerance needs into grade choice.

- Surface Treatment Compatibility: Pre-consider anodizing and other finishing suitability.

Aluminum CNC Precision Machining Capabilities

Micron-Level Machining Accuracy

Achieve consistent tolerance levels with micron precision, ensuring dimensional accuracy for complex aluminum parts. Capable of machining a wide range of sizes and intricate geometries.

Multi-Axis & Compound Machining

Utilize advanced multi-axis CNC machining for spatial and curved components. Multi-station processes reduce setups and improve repeatability and surface quality.

Process Control & Quality Assurance

Optimize cutting parameters to control deformation and stress, even on thin-walled or ring-shaped parts. Instrumented quality inspections ensure visual and dimensional compliance.

Full traceability throughout the manufacturing workflow ensures reliability and adherence to stringent quality standards.

Typical Applications of Aluminum Components

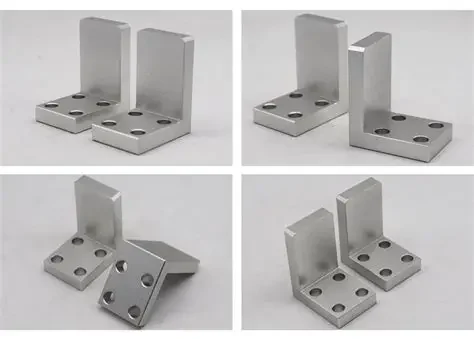

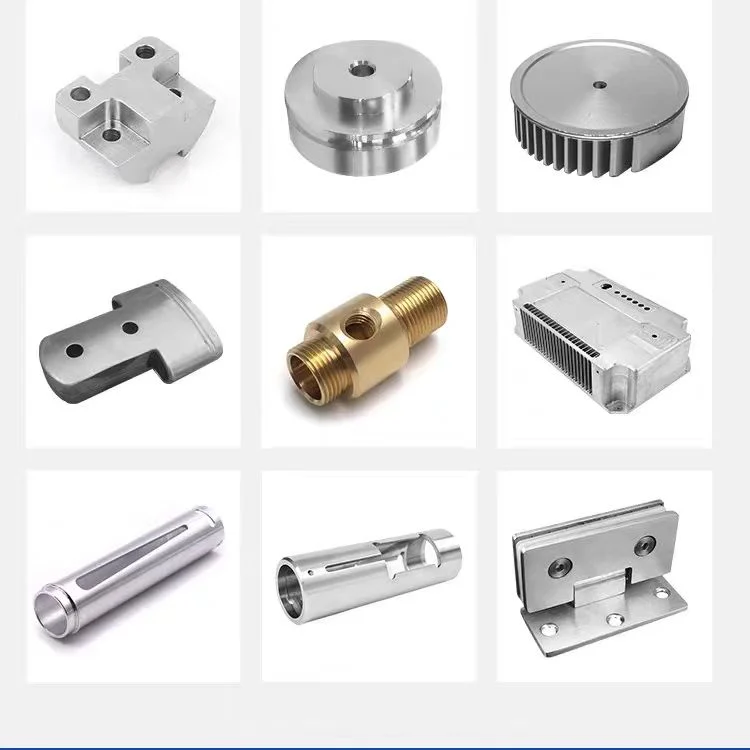

Equipment and Mechanical Structural Parts

Frames, mounts, and installation plates in machinery require weight reduction while maintaining structural stability.

Electronic and Electrical Structural Components

Electronic housings and protective covers provide strength, thermal management, and partial EMI shielding with a lightweight, sleek design.

Precision Motion and Guiding Support Components

Guide rails and mounting bases for transmission parts optimize precision, reduce inertia, and improve dynamic response.

Other Custom Aluminum Parts

Low-volume, non-standard structural or functional brackets meet projects demanding design flexibility and responsive manufacturing. These housings ensure quality and customized solutions.

Aluminum Surface Finishing & Appearance Quality Control

Compatible Surface Finishing Processes

Support anodizing pretreatment including sandblasting and custom finishes. Consultations available for color and finish tailored to use and aesthetics.

Appearance Quality Controls

Minimize burrs and scratch defects as the foundation for finishing. Inspect color uniformity, surface smoothness, and structural integrity including laser-cutting inspection.

Branding & Identification Solutions

Designated marking areas preserve client logos or product IDs. Ensure consistent surface appearance aligned with brand identity and materials like plastic.

Project Collaboration and Custom Aluminum Part Ordering Process

Requirement Gathering & Drawing Review

Customers submit detailed drawings or specifications including environment and key dimensions to facilitate precise CNC machining.

Our team performs thorough feasibility analysis and provides preliminary recommendations.

Quotation and Proposal Confirmation

Receive a comprehensive quote covering materials, process steps like milling, and batch volumes.

Agreement on specifications, delivery timelines, and inspection criteria prior to production start.

Sample Production and Refinement

Prototype machining with detailed inspections for customer approval.

Iterative feedback cycle optimizes process and design for best performance.

Mass Production and Delivery

Controlled batch machining according to approved workflows ensures consistency.

Quality sampling inspections, secure packaging, and export logistics support complete delivery.

ZSCNC delivers quality and precision at scale.