Titanium Materials for High Performance Precision Machining

Exceptional Strength to Weight Ratio and Biocompatibility for Aerospace and Medical Precision Components

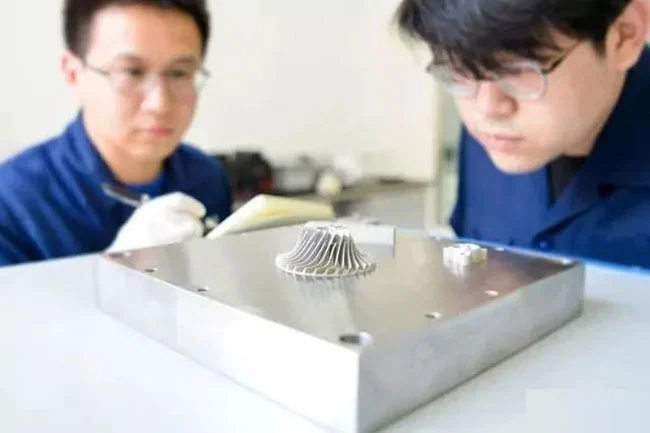

ZSCNC specializes in titanium and titanium alloys for precision CNC machining, delivering unmatched quality and reliability.

Titanium and Titanium Alloy Properties Overview

Strength to Weight Advantage

Titanium alloys offer exceptional strength while being much lighter than steel, perfect for aerospace structural parts. They provide weight reduction combined with load safety in fixtures, brackets, and connectors.

Corrosion Resistance & Environmental Adaptability

A stable dense oxide film delivers outstanding resistance to seawater, bodily fluids, and chemicals. Suitable for humid, saline, and in vivo environments.

Biocompatibility & Medical Suitability

Medical grade titanium alloys are compatible with human tissue, ideal for orthopedic implants, dental bases, and long-term implants. Minimal MRI interference is noted, making them highly sought after in the medical industry.

Thermal Stability & High Temperature Performance

Certain titanium alloys maintain strength and dimensional stability at medium to high temperatures, making them suitable for aerospace engine peripheral parts.

Titanium Materials Types and Specifications

Material Types Overview

Industrial Pure Titanium TA Series offers moderate strength, excellent corrosion resistance, and biocompatibility.

Common Titanium Alloys TC Series are alpha plus beta alloys designed for higher strength and fatigue performance.

These materials are ideal for aerospace and mechanical components requiring durability and precision.

Forms and Size Ranges

Bars are suited for shafts and fasteners, available in typical diameters and lengths to meet industrial needs.

Plates and sheets cater to thin-wall components, with strict controls over thickness and maximum size.

Blanks and forgings are optimized for high load bearing parts with rough blank sizes tailored for machining.

Material Standards and Certification

Our materials comply with ASTM, JIS, and other international standards, ensuring industry-grade quality.

ZSCNC guarantees full quality assurance, traceability, and supports customer-specified certifications for every order.

CNC Precision Machining for Titanium: Capabilities & Process Adaptation

Machining Challenges

- Low thermal conductivity causes heat concentration; requires optimized cutting parameters and tooling.

- High strength and elasticity lead to vibration and deformation; demands advanced clamping and path planning.

Process Strengths

- CNC Turning and Milling enable small features, intricate surfaces, and thin walls.

- Multi-axis machining ensures precision and superior surface quality control.

Tooling & Fixture Solutions

- Specialized coated cutting tools extend tool life for titanium machining.

- Custom fixtures reduce deformation and guarantee repeatability.

Temperature & Deformation Management

- Optimized cutting speeds, cooling, and path planning minimize heat and stress in CNC machining.

- Dimensional control verified before and after finishing ensures precision.

Typical Applications of Titanium Parts in Aerospace, Medical, and High-End Industrial Sectors

Aerospace and Aviation Applications

Titanium parts in aerospace reduce weight and enhance reliability in cabin structural connectors, landing gear, and engine peripheral brackets. Fasteners for satellites and spacecraft provide corrosion and temperature resistance for demanding environments.

- Weight reduction critical for fuel efficiency

- High strength-to-weight ratio boosts safety and reliability

- Corrosion and extreme temperature resistance for longevity

Medical and Life Sciences Equipment

Titanium’s rigidity and lightweight features are ideal for orthopedic fixation plates, joint frameworks, and medical dental implant bases. High-end medical device frames benefit from superior biocompatibility and durability.

- Rigid yet lightweight for patient comfort and performance

- Biocompatible with minimal rejection risk

- Durable against long-term wear and sterilization processes

High-End Industrial and Precision Mechanisms

Titanium components improve performance in high-speed drive and transmission parts by reducing inertia. Corrosion-resistant parts are essential for chemical plants and specialty fluid channels, enhancing operational reliability. Our commitment to quality is reflected in every part, following strict quality control processes.

- Lightweight components improve machine response and precision

- Strong corrosion resistance extends lifespan in harsh environments

- Precision machining ensures perfect fit and function

Quality Control and Inspection for Titanium Components

Material Sourcing & Certificate Verification

Grade melt batches are performance-verified during incoming inspection. Mandatory traceable quality documentation is retained throughout, ensuring compliance with material standards.

Dimensional Accuracy & Tolerance Control

Critical form tolerances, coaxiality, and fit precision are maintained, especially for thin-wall, complex parts. Sampling and 100% final inspections ensure key dimensions meet standards.

Surface Condition & Defect Inspection

Quantitative roughness measurement and visual nondestructive testing detect cracks and defects, assuring functional assembly compliance.

Cleanliness & Post-Processing Controls

Strict cleanliness protocols prevent contamination and residue in medical and precision assemblies. Surface treatments and passivation processes are validated for reliability.

ZSCNC prioritizes traceability and 100% inspection for critical components, ensuring titanium parts meet the highest quality standards.

Industry Specific Collaborative Development & Prototyping Workflow

Requirement Clarification & Material Suitability Assessment

Review drawings thoroughly to determine usage and life expectancy. Recommend alloys balancing strength, weight, and cost for informed decisions.

This step ensures optimal material selection to support durable and cost-effective production tailored to industry needs.

Process Planning & Prototype Execution

Engineering develops custom CNC processes including tooling and inspection plans for small batch prototyping.

Validate structure, fit, and critical performance with precise prototype testing before scaling.

Mass Production & Continuous Improvement

After prototype approval, scale to stable production with fine-tuned parameters enabled by advanced five-axis CNC control.

Maintain detailed process data for ongoing design iteration and lifecycle management to optimize manufacturing efficiency.