Aluminum CNC milling service for German machinery parts

You need reliable, precise aluminum CNC milled components for German machinery – not excuses. I run a specialized aluminum CNC milling service for German machine builders, OEMs, and automation integrators, focused on tight tolerances

Aluminum CNC milling capabilities for German machinery parts

Our aluminum CNC milling service for German machinery parts is built around flexible capacity and stable quality, so you can move from prototype to series without changing suppliers.

3-axis, 4-axis, and 5-axis milling for complex geometries

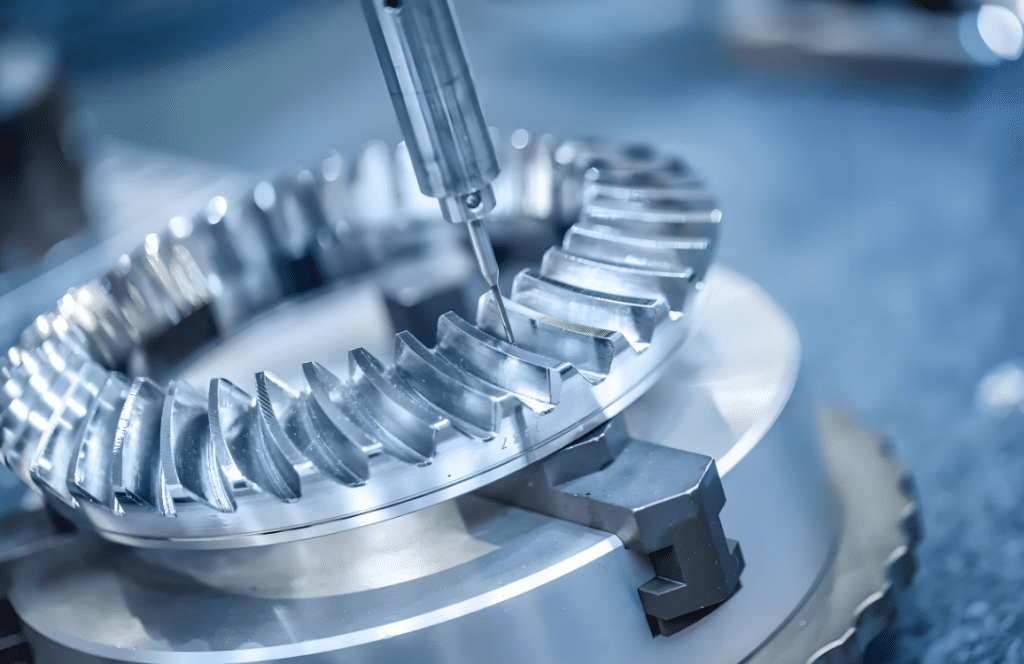

We run a mixed setup of 3-axis, 4-axis, and full 5-axis aluminum CNC milling centers to cover both simple plates and complex precision components:

- 3-axis: cost-efficient milling for plates, mounting plates, brackets, and simple housings

- 4-axis: improved access for profiles, rotary parts, and multi-side machining

- 5-axis aluminum CNC milling: for complex geometries, deep pockets, tight features, and reduced setups on high-precision German machinery parts

For especially complex parts with undercuts and multi-angle features, we route work to our dedicated 5-axis CNC machining for complex aluminum parts line.

Supported aluminum part types

We regularly supply CNC milled aluminum components for German OEMs such as:

- Frames and base plates for machines and automation cells

- Brackets, mounts, and adapters for sensors, drives, and robotics

- Housings and enclosures for electronics, control systems, and power units

- Covers, doors, and panels with functional and cosmetic surfaces

If you need custom aluminum CNC machined parts like tailored plates, frames, or enclosures, we run them on our custom aluminum CNC machined parts line.

Prototype, small batch, and series production

We support the full lifecycle for German machine builders:

- Prototype runs: fast-turn, flexible, ideal for design validation and engineering tests

- Small batch production: bridge tooling, pilot lines, and low-volume machinery

- Series production: stable process, repeatable quality, and controlled costs for recurring orders

You can start with a few prototype aluminum parts for German manufacturers and scale to hundreds or thousands without changing the process.

Maximum part size and production capacity

For Germany-focused aluminum CNC milling projects, we typically offer:

- Machining envelope: up to approx. 1,000 mm × 600 mm × 500 mm (L × W × H) depending on the machine

- Part size range: from small precision inserts and brackets to large structural plates and frames

- Production capacity: multiple shifts and parallel machines for ongoing series, Kanban, and scheduled call-offs

This setup lets us handle both tight tolerance aluminum CNC parts for precision engineering and robust industrial aluminum components for heavier machinery, all with lead times and batch sizes suited to German OEM expectations.

Aluminum alloys for German machinery parts

For our aluminum CNC milling service for German machinery parts, we only use industrial-grade, fully traceable alloys that match the expectations of German OEMs, automation builders, and robotics companies.

Common aluminum grades for CNC milling

We machine the most requested alloys for precision aluminum CNC milling in Germany:

- 6061-T6 – The go-to choice for frames, plates, brackets; strong, stable, and cost-effective.

- 7075-T6 – High-strength alloy for high-load and dynamic parts in robotics and special machines.

- 5083 – Great for structures and components that need better corrosion resistance.

- 2026 – Used when fatigue resistance matters, especially in high-cycle motion systems.

- MIC-6 cast plate – Very flat and stable for precision milled aluminum plates and frames, bases, and reference surfaces.

If you need more detail on achievable tolerances with these alloys, we break that down in our aluminum CNC machining tolerances for automation equipment guide.

Certified, traceable aluminum materials

For German industry clients, documentation matters as much as the part itself. That’s why we provide:

- Mill certificates and material test reports (MTRs)

- Batch-level traceability for every aluminum bar, plate, or block

- RoHS and REACH compliant aluminum for EU and German regulations

This makes our shop a reliable German machine builders aluminum parts supplier for both audits and long-term series production.

Why German machinery uses aluminum

German automation and machinery makers choose aluminum because it hits the sweet spot between performance and cost:

- Weight reduction – Lighter aluminum frames and plates for machinery mean faster axis movement and lower power demand.

- High specific strength – Alloys like 7075-T6 deliver strength close to steel at a fraction of the weight.

- Good thermal properties – Ideal for aluminum heat sinks CNC machining, housings, and thermal management components.

- Corrosion resistance – With anodizing or passivation, parts last longer on the shop floor and in harsh environments.

Choosing the right aluminum alloy

We help German engineers pick the best alloy for each application:

- Automation & conveyors – 6061-T6 or 5083 for brackets, mounting plates, and structural parts.

- Robotics & handling systems – 7075-T6 and 2026 for tight tolerance aluminum CNC parts with high stiffness and low weight.

- Industrial machinery & enclosures – 6061-T6 or MIC-6 for custom aluminum enclosures CNC machined, machine bases, and precision plates.

Share your load cases, environment, and surface finish needs, and we’ll recommend the most cost-effective alloy and machining route for your CNC milled aluminum components for German OEMs.

Precision and tolerances for aluminum CNC milling

For aluminum CNC milling service for German machinery parts, we focus on stable, repeatable accuracy that fits German engineering standards.

Standard and tight tolerances for German aluminum parts

For most CNC milled aluminum components for German OEMs, we work with:

- Standard tolerances: ±0.05 mm to ±0.02 mm on critical dimensions

- Tight tolerance aluminum CNC parts: down to ±0.005 mm on selected features, depending on geometry, setup, and alloy

- Hole and shaft fits: H7/g6, H7/h6 and similar fits commonly used in German machinery and automation equipment

- Flatness and parallelism: controlled for precision aluminum plates and frames used in bases, mounting plates, and linear guide interfaces

We always align our tolerance scheme with your technical drawing (ISO / DIN) and function of the part, not just a generic machine capability.

Measuring equipment and CMM inspection

To support precision aluminum CNC milling for Germany-focused projects, we use:

- CMM inspection for complex 3D surfaces and 5-axis aluminum CNC milling parts

- Height gauges, pin gauges, micrometers, bore gauges for fast in-process checks

- Surface roughness testers to verify Ra requirements on sealing faces and sliding surfaces

For deeper insight into our metrology approach and CNC machining accuracy, you can review our detailed breakdown of industrial CNC machining accuracy standards and 0.005 mm tolerance control on our site.

Process control for repeatable accuracy

For series production of aluminum brackets, frames, and housings, we lock in accuracy through:

- Documented CNC programs and tool lists for each German customer part number

- Tool wear monitoring and offset control for long runs

- SPC sampling on key dimensions to catch drift before it becomes scrap

- Dedicated fixtures for repeat setups on recurring German orders

This lets us deliver repeatable precision from prototype to small batch and ongoing series for German machine builders.

First Article Inspection (FAI) and documentation

For German OEM approvals, we support a full First Article Inspection flow:

- Dimensional report against your drawing (with CMM data where needed)

- Material certificates and hardness data matched to the alloy (e.g. 6061‑T6, 7075‑T6)

- Marked control dimensions and ballooned drawings if requested

- Signed FAI/ISIR documentation for your PPAP or internal release process

Once the FAI for your aluminum CNC milled components is approved, we lock that configuration and use it as the reference for all repeat orders for German machinery.

Surface finishes for aluminum CNC machined parts

For our aluminum CNC milling service for German machinery parts, we offer surface finishes that focus on function, durability, and clean industrial aesthetics.

Standard as‑machined finish

For most German machine builders, the as‑machined finish is enough for functional components:

- Visible tool paths, but controlled and consistent

- Deburred edges and cleaned surfaces

- Ideal for internal parts, jigs, fixtures, and hidden aluminum frames and plates

- Cost‑effective and fast, perfect for prototype aluminum parts for German manufacturers

Anodizing for German equipment

We run precision aluminum CNC milling Germany with anodizing in-house and through certified partners:

- Clear anodizing – for clean, technical look on housings, brackets, and mounting plates

- Black anodizing – widely used on aluminum enclosures CNC and robotics parts (low reflection, professional appearance)

- Colored anodizing – for part identification on automation lines and special purpose machinery

- Improved corrosion resistance, harder surface, and better wear resistance

- Suitable for aluminum 6061-T6 CNC milling and aluminum 7075-T6 CNC machining

Powder coating, bead blasting, polishing, passivation

To match different German machinery environments:

- Bead blasting – uniform matte finish, removes minor marks, ideal before anodizing or powder coating

- Powder coating – thick, durable coating for harsh factory conditions and outdoor use

- Polishing – smoother surface for visible panels, covers, and design‑critical aluminum CNC milled components

- Chemical passivation / conversion coating – improved paint / adhesive bond and added corrosion resistance

For packaging, automation, and production systems, we often combine bead blasting with anodizing, similar to what we do for CNC machining for packaging machinery parts.

How finishes improve durability in German machinery

Surface treatments are not just cosmetic for CNC milled aluminum components for German OEMs:

- Protect aluminum against coolants, cleaning agents, and humidity in factories

- Increase wear resistance on sliding and contact surfaces

- Reduce corrosion in high‑duty cycles and multi‑shift production environments

- Extend service life of aluminum frames and plates for machinery, heat sinks, and precision housings

With the right finish, your tight tolerance aluminum CNC parts stay accurate, look professional, and last longer in demanding German industrial applications.

Industries and applications in German machinery

Our aluminum CNC milling service for German machinery parts is built around real use on factory floors in Germany.

Aluminum CNC milling for automation and production lines

We supply precision aluminum CNC milling in Germany for:

- Assembly and packaging lines

- Handling and transfer systems

- Machine frames, mounting plates, and positioning units

Lightweight aluminum frames and plates for machinery reduce inertia, speed up motion, and lower drive loads, which is exactly what German automation builders need.

CNC aluminum parts for robotics, conveyors, and special machines

For robotics and special purpose machines, we machine:

- Aluminum brackets and mounting plates milling for robots and grippers

- Custom CNC machining for conveyor systems (guides, supports, side plates)

- Custom aluminum enclosures CNC for control units and sensors

When projects combine machined parts with formed sheet components, we also support compatible complex-shaped sheet metal parts used in the same German equipment layouts: complex sheet metal parts.

Precision components for industrial equipment

German OEMs use our CNC milled aluminum components for German OEMs in:

- Test rigs and measurement systems

- Drives and motion platforms

- Aluminum heat sinks CNC machining for drives and power electronics

Typical parts we deliver to German machine builders include:

- Precision milled aluminum plates and frames

- Tight tolerance aluminum machining for Germany (bearing seats, reference faces)

- High-precision aluminum housings, covers, and anodized aluminum CNC machined parts

- Brackets, sensor mounts, and cooling plates

Every part is produced and inspected with German-style expectations in mind: stable quality, repeatability, and clear documentation.

Why choose our aluminum CNC milling service for German clients

European-level quality, global pricing

We position our aluminum CNC milling service for German machinery parts at European-level quality with global-competitive pricing. You get:

- Tight-tolerance, precision aluminum CNC milling for Germany without typical EU cost overheads

- Stable, repeatable quality backed by strict process control and ISO-style workflows

- Transparent quotes and clear cost breakdowns so purchasing teams can compare easily

For an overview of our core capabilities, check our dedicated page on CNC milling services: high-precision CNC milling capabilities.

Lead times and logistics for German manufacturers

We plan production and shipping specifically around German OEM and Tier-1 supplier expectations:

- Short lead times for prototype aluminum parts for German manufacturers

- Scheduled batches for series production, synced with your build plan

- Familiar Incoterms, customs paperwork, and reliable forwarders used to export aluminum CNC parts to Germany

Experience with Germany and the EU

We already ship CNC milled aluminum components for German OEMs and EU customers, so we know:

- German drawing standards, tolerances, and documentation habits

- How to pack aluminum frames, plates, and housings safely for long-distance transport

- Requirements around RoHS / REACH compliant aluminum parts and traceability

Support for German engineers and project teams

We work the way German engineers work:

- Direct technical communication in clear, straightforward English

- Full set of drawings, CMM inspection reports, and certificates on request

- Fast feedback on design changes, plus stable handling of repeat orders and revisions

If you need both aluminum and multi-axis work, we also offer advanced options like our 5-axis CNC machining services for complex components: 5-axis CNC machining for high-precision parts.

Design guidelines for aluminum CNC parts for German machinery

When we design aluminum CNC milled components for German machine builders, we focus on clean geometry, stable machining, and predictable costs.

Recommended wall thickness, holes, and radii

For most precision aluminum CNC milling in Germany, these rules work well:

- Wall thickness

- Standard: ≥ 2.0–2.5 mm for 6061-T6 / 5083

- Large pockets: ≥ 3.0 mm to avoid vibration and deformation

- Hole sizes

- Milled (non-drilled) holes: ≥ 1.0 mm diameter

- Depth: ideally ≤ 5× diameter for stable machining

- Inside radii

- Match tool size: R ≥ 1.0 mm for small pockets, R ≥ 3.0 mm for deep pockets

- Use consistent radii across features to reduce tool changes and cost

Keeping features “tool-friendly” helps us run your aluminum 6061-T6 CNC milling faster and more stable, especially on complex frames and plates.

Threading, undercuts, and tolerances

To keep tight tolerance aluminum CNC parts practical and affordable:

- Threads

- Prefer standard metric threads (e.g. M3–M12)

- Use through holes where possible; blind holes need extra care and cost

- Allow lead-in chamfers (0.5–1.0 mm × 45°) for better assembly

- Undercuts

- Avoid hidden or unnecessary undercuts; use standard tool sizes if required

- Consider redesigning to two-part assemblies instead of extreme undercuts

- Tolerances

- General features: ±0.05 mm is usually enough for German industrial equipment

- Critical fits: ±0.01–0.02 mm only where truly needed

- Applying “H7” / “g6” type fits only to key bores/shafts keeps costs under control

For deeper background on suitable CNC tolerances and feature design, our short CNC machining 101 guide is a solid reference for engineering teams.

Cost-saving DFM tips for German machine builders

To keep your prototypes and small-batch aluminum CNC production in Europe competitive:

- Use one-sided machining where possible; reduce setups

- Avoid very deep pockets and ultra-thin ribs unless function demands it

- Group hole sizes and radii to reduce tool changes

- Use standard fasteners and dowels instead of custom fits where possible

- Keep drawing requirements clear: only call out what really matters (tolerances, flatness, critical surfaces)

These DFM choices often cut cycle time and scrap rate without hurting performance of German automation equipment and robotics.

How we review CAD files and give manufacturability feedback

Every RFQ for aluminum CNC milling service for German machinery parts goes through a quick DFM review:

- We check wall thickness, tool access, clamping, and deformation risk

- We highlight overly tight tolerances, non-standard threads, and risky undercuts

- We provide practical suggestions: small design tweaks, alternative radii, or tolerance relaxations

- If needed, we return marked-up PDFs or screenshots with clear comments for your engineers

This way, your custom aluminum machining for industrial equipment moves from CAD to stable, repeatable production with fewer surprises and lower total cost.

Quality control and certifications for German market

When it comes to aluminum CNC milling service for German machinery parts, we run quality the same way German OEMs build machines – structured, documented, and repeatable.

ISO 9001 and robust quality systems

We operate under an ISO 9001–based quality system tailored to precision aluminum CNC milling for Germany-focused orders. Every job gets:

- Controlled drawings, revisions, and change history

- Defined process plans for each aluminum part family

- Tooling, programs, and fixtures locked under document control

Our quality control framework is aligned with what German machine builders expect from a long-term supplier.

In-process and final inspection workflow

For tight tolerance aluminum CNC parts, we don’t rely on end checks only. We use:

- In-process inspection at defined checkpoints (critical dimensions, threads, fits)

- CMM inspection and calibrated gauges on precision aluminum components

- Final inspection reports attached to each batch before shipping to Germany

You can see how we organize and execute this QA approach on our detailed quality control and inspection page.

Material reports, CoCs, and full traceability

For CNC milled aluminum components for German OEMs, traceability is non‑negotiable. We provide on request:

- Material test reports (MTR / EN 10204 3.1) for aluminum 6061-T6, 7075-T6, 5083, 2026, MIC-6, and more

- Certificates of Conformity (CoC) covering drawing, material, and surface finish

- Heat/batch number tracking from raw aluminum bar/plate to finished CNC part

This makes audits, customer approvals, and PPAP-style documentation straightforward for German manufacturers.

RoHS and REACH compliant aluminum CNC parts

All aluminum CNC machining for German automation equipment and industrial machinery follows EU rules:

- RoHS-compliant materials and finishes (no restricted substances above limits)

- REACH-compliant sourcing and declarations where required

- Traceable records in case your quality or compliance team needs proof during audits

We treat German and EU compliance as a base requirement, not an add‑on, so your CNC milled aluminum components arrive ready for integration, documentation, and customer acceptance.

Real aluminum CNC parts for German machinery

Sample aluminum frames, plates, and housings

We supply aluminum CNC milled components for German machine builders that go straight into production lines and special-purpose machines. Typical parts we ship to Germany include:

- Precision milled aluminum plates and frames for automation cells, fixtures, and base plates

- CNC machined aluminum housings and enclosures for drives, controllers, sensors, and robotics modules

- Aluminum brackets and mounting plates for conveyors, safety guarding, and handling systems

All parts are delivered with clear labeling, drawings, and traceability to fit into your existing ERP and documentation flow.

Prototype to production for German OEMs

We support German OEMs from small-batch aluminum prototypes to full series production:

- 1–20 pcs for design validation and testing

- 20–200 pcs for pilot runs and pre-series builds

- Scaled series with stable processes, controlled fixtures, and locked programs

For complex 5-axis parts, we follow similar standards to those in our custom CNC machining services for overseas buyers so you get predictable quality from prototype to series (custom CNC machining supplier for overseas buyers).

Surface finish and tolerance examples

We regularly produce tight tolerance aluminum CNC parts for German precision engineering, such as:

- Milled plates with flatness ≤ 0.02–0.05 mm and hole position tolerances down to ±0.01–0.02 mm

- Anodized aluminum CNC machined parts (clear or black) with controlled cosmetic faces

- Bead-blasted enclosures with clean edges and consistent surface structure

We validate key dimensions on CMM and share sample reports with you before ramping up volume.

Handling repeat orders and engineering changes

For German customers, we keep long-term process stability at the center:

- We lock CNC programs, fixtures, and inspection plans for every article number

- Every engineering change (rev level) is version-controlled with updated drawings and FAI reports

- Repeat orders use the same verified setup, so your aluminum CNC parts are consistent lot after lot

This way your German machinery — from robotics to conveyor systems — gets the same reliable aluminum components every time, even when designs evolve.

FAQ – Aluminum CNC milling service for German machinery parts

What are your minimum order quantities for aluminum CNC parts?

- We accept single prototype aluminum parts for German engineers.

- Typical small batch runs start from 5–10 pcs.

- For series production, we scale from 50 pcs up to several thousand CNC milled aluminum components for German OEMs.

- No strict MOQ – we quote based on part complexity, aluminum grade, and tolerance.

How fast can you ship aluminum CNC parts to Germany?

- Standard lead time: 7–15 working days for most aluminum CNC projects.

- Urgent prototypes: as fast as 3–5 working days, depending on complexity.

- Shipping options to Germany:

- Express air (DHL/UPS/FedEx) – ideal for prototypes and urgent spare parts.

- Economy air – cost-effective for small batches.

- Sea freight – for large, repeat orders and heavy aluminum frames or plates.

- We provide DDP / DAP options on request so German machine builders know the landed cost upfront.

Which CAD file formats and drawing standards do you support?

We work with all common formats German engineers use:

- 3D files: STEP, STP, IGES, X_T, Parasolid, SLDPRT

- 2D drawings: PDF, DWG, DXF with ISO / DIN-compliant tolerances and GD&T

- We follow German and European drawing standards (ISO 2768, surface symbols, fits, etc.).

- If you’re not sure which material to specify, our guide on how to select precise CNC machining materials can help with aluminum grade choices: how to select precise CNC machining materials.

What tolerances, surface finishes, and materials can you offer?

- Tolerances for aluminum CNC milling:

- Standard: ±0.05 mm

- Tight tolerance aluminum CNC parts: down to ±0.01 mm or better on critical features (after review).

- Surface finishes for aluminum CNC machined parts:

- As-machined

- Anodizing (clear, black, colored)

- Bead blasting + anodizing

- Powder coating, polishing, light brushing

- Aluminum alloys for German machinery parts:

- 6061-T6, 7075-T6, 5083, 2026, MIC-6 and more

- Material with test reports and traceability, suitable for RoHS and REACH-compliant projects.

If you send the 3D model + 2D drawing, we’ll confirm what tolerance, finish, and aluminum alloy combination makes the most sense for your specific German machinery application.

Reviews

There are no reviews yet.