Pre Production Review & Process Validation

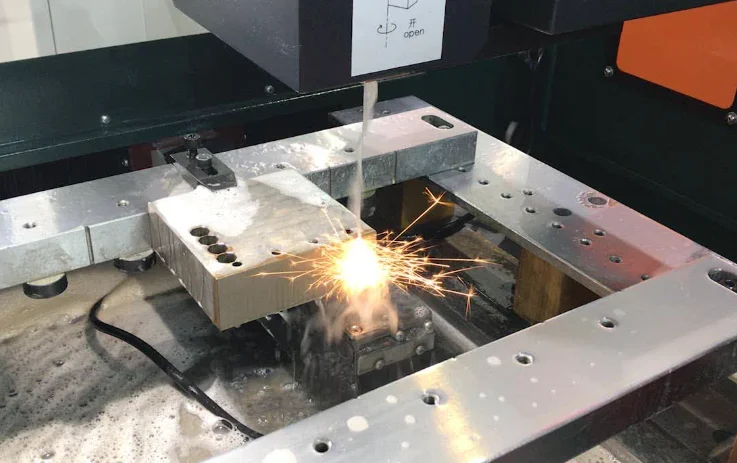

Comprehensive manufacturability evaluation of drawings, materials, and tolerances. First piece EDM trials establish precise process windows, essential for machining success.

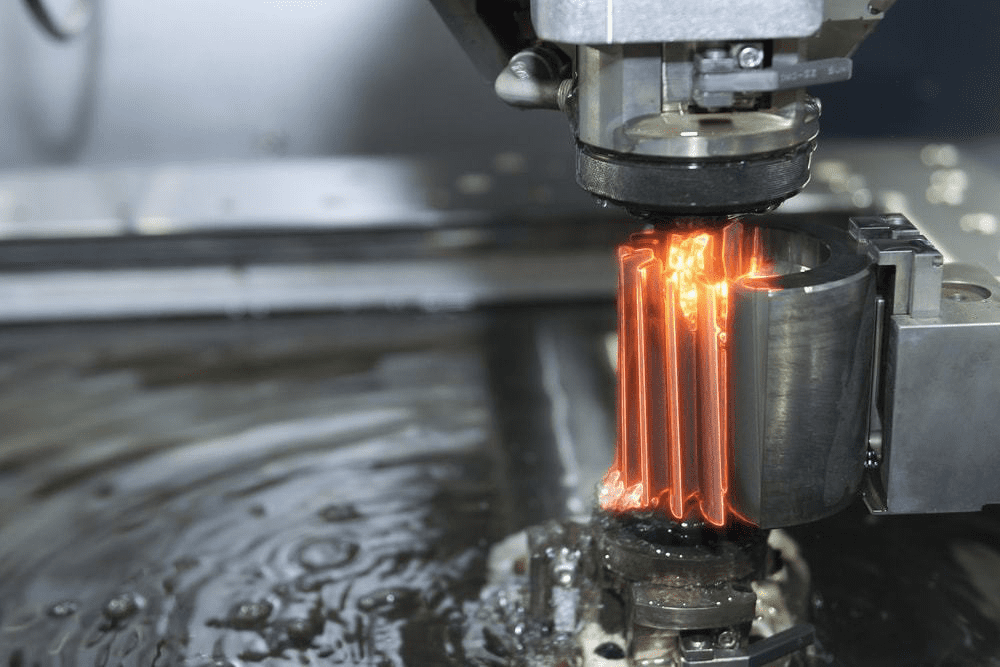

Specialized EDM services designed for hard-to-machine high hardness, deep cavity, and micro-structured metal components. Delivering stable, precise, and scalable production.

Electrical Discharge Machining removes metal by pulsed discharge between electrode and workpiece. Unaffected by material hardness, ideal for molds, precision parts, and complex structures.

Customized maximum workpiece dimensions tailored per project requirements. Suitable thickness range for cutting and cavity depth. Precise electrode size and travel specifications ensure flexibility in machining.

Achieve micron-level dimensional tolerance with high geometric accuracy, including perpendicularity, parallelism, and coaxiality. Stable batch-to-batch consistency supports volume orders.

China custom CNC machining supplier for overseas buyers offering ISO certified precision parts fast quotes low MOQ DDPFOB shipping

Custom CNC machining for packaging machinery parts with tight tolerances durable food grade materials and fast delivery

Wire EDM machining services for precise complex parts from prototypes to production with tight tolerances and fast lead times

At ZSCNC, we specialize in delivering precision EDM solutions tailored for complex materials and parts. Our advanced technology ensures exceptional accuracy to meet your high standards.

ZSCNC provides top-tier electrical discharge machining services.

ZSCNC provides EDM-specific design optimization advice for easier manufacturing and flawless assembly.

Comprehensive manufacturability evaluation of drawings, materials, and tolerances. First piece EDM trials establish precise process windows, essential for machining success.

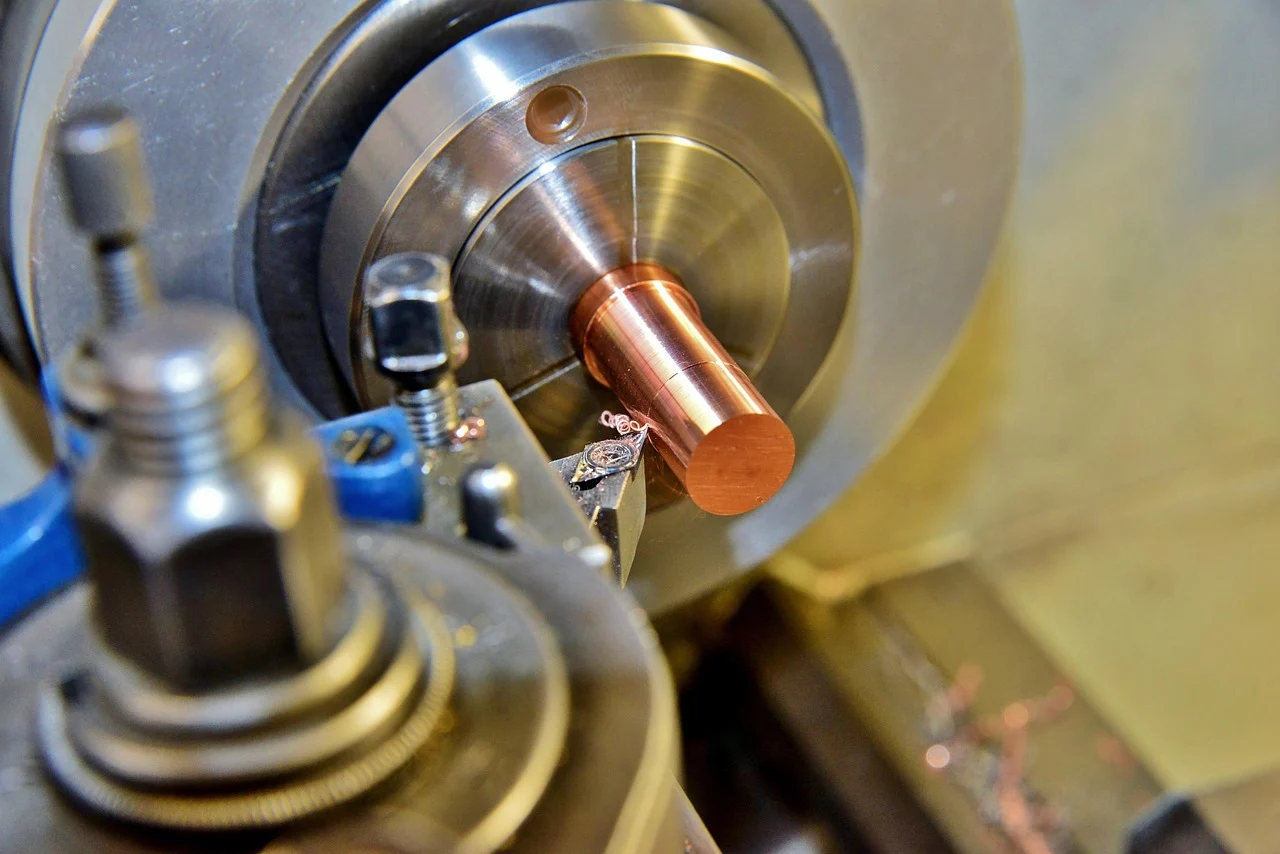

Track electrode wear, pulse parameters, and machining times to ensure reproducibility. Perform intermediate inspections to promptly address deviations during milling machining processes.

Use high precision gauges and custom fixtures to verify critical dimensions. Focused measurement of mating surfaces ensures assembly accuracy compatible with turning machining standards.

Deliver detailed inspection reports on customer demand confirming product conformance and quality standards, reinforcing ZSCNC’s commitment to excellence in five-axis machining.

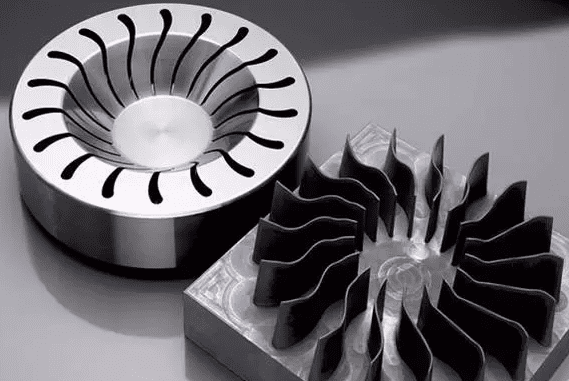

Complex cavities and inserts for plastic die casting, powder metallurgy, and stamping molds — engineered with precision for optimal performance.

Components with fine slots, narrow gaps, and sharp geometries in actuators, guides, and clamping devices to ensure exact motion control.

Small, high-precision parts requiring sharp edges and consistently repeatable geometries for reliable instrumentation.

Rapid trial builds featuring complex designs that reduce tooling costs and shorten development cycles, ideal for rapid prototyping.

Provide 2D, 3D drawings, material specs, tolerances, surface finish, and

target quantities. Highlight critical features like deep cavities, sharp

angles, or microstructures.

Assess machining complexity, electrode needs, and batch sizes. Deliver a

comprehensive quote including lead times, precision, and quality control

highlights.

Produce sample parts for precision or novel structures to validate

feasibility. Finalize process parameters before volume production. This

includes milling and turning processes.

Execute production with scheduled inspections and reporting. Optionally

retain process data for seamless repeat orders, including advanced

five-axis machining techniques.