Custom CNC Machining Supplier for Automotive Parts in Netherlands and Belgium

You need precision CNC automotive parts in the Netherlands and Belgium that fit first time, arrive on time, and meet EU automotive standards. That’s exactly what I deliver with ZSCNC – a focused custom CNC machining supplier for automotive parts in Netherlands and Belgium, built around the needs of serious engineers, tuners, and vehicle builders in the Benelux region.

I supply custom machined auto components for Dutch and Belgian customers, from prototype CNC auto parts to low-volume CNC production runs. Every part is produced on modern CNC milling and turning centers, with tight tolerances down to ±0.01 mm, proven processes, and material traceability suitable for both OE-style and aftermarket automotive machining.

Key advantages for Netherlands and Belgium:

- High precision & repeatability – EU-grade aluminum and steel automotive machining services for brackets, housings, flanges, engine and suspension parts.

- Fast, reliable lead times – optimized for Benelux CNC machining automotive projects, with efficient shipping to the Netherlands and Belgium.

- EU compliance in mind – parts and documentation aligned with European automotive requirements, ideal for tuning, conversions, and specialist builds.

I work closely with:

- Aftermarket performance and tuning shops needing CNC milling for car tuning in Benelux

- Custom vehicle conversion companies (EV swaps, campervans, off‑road builds) needing custom vehicle conversion parts CNC

- Racing and motorsport teams requiring CNC machining for racing car components

- Classic car workshops needing low-volume CNC production in Belgium and the Netherlands for obsolete parts

If you’re looking for a reliable CNC machining supplier in Netherlands or Belgium for custom CNC machining automotive parts in Europe, I position ZSCNC as your practical, no-nonsense partner for CNC machined components for EU aftermarket and custom cars—with the precision, speed, and consistency your projects demand.

Custom CNC machining supplier for automotive parts in Netherlands and Belgium

As a dedicated custom CNC machining supplier for automotive parts in Netherlands and Belgium, I focus on precise, repeatable parts for tuning shops, race teams, OEM suppliers, and custom builders across Benelux.

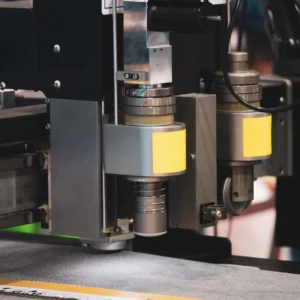

CNC milling for complex automotive parts

I run 3-axis, 4-axis, and 5-axis CNC milling to handle everything from simple brackets to complex engine and drivetrain components. This lets me machine:

- Precision brackets and mounts

- Gearbox and differential housings

- Custom flanges and adapters

- Engine and transmission covers and plates

- Structural suspension parts and knuckles

For more details on how I handle complex geometries and tight specs for EU automotive customers, you can check my dedicated page on custom CNC machined automotive parts.

CNC turning and multi-axis machining

For round and symmetrical components, I use CNC turning and multi-axis machining to keep dimensions tight and surfaces clean, ideal for:

- Shafts, spacers, and bushings

- Custom fittings and threaded adapters

- Hubs, pulleys, and wheel-related parts

- Precision engine and transmission turned parts

This setup is well suited for precision CNC automotive parts in Netherlands and custom machined auto components in Belgium.

Prototype to small and medium series for Benelux

I support prototype, small-batch, and medium series CNC machining tailored to the Benelux automotive market:

- One-off and prototype CNC auto parts Netherlands for testing and validation

- Low-volume CNC production Belgium for tuning parts, race components, and niche conversions

- Stable, repeatable batches for aftermarket and specialist workshops

If you’re looking to balance cost and flexibility for low-volume runs, I also share practical tips on my guide about reducing machining cost for low-volume automotive CNC parts.

Automotive-grade materials for CNC machining

For Dutch and Belgian automotive projects, I only use proven automotive-grade materials and match them to your real road conditions and performance targets.

Aluminum CNC machining (6061, 7075 and other alloys)

For lightweight, high-precision CNC automotive parts in the Netherlands and Belgium, aluminum is often the best choice:

- 6061 aluminum – Ideal for custom CNC brackets, housings and flanges where strength, cost and machinability need to be balanced.

- 7075 aluminum – Used for performance and racing components that need high strength with low weight (suspension parts, steering components, motorsport brackets).

- Other automotive aluminum alloys are available on request for EU-compliant parts.

If you want to go deeper into choices, I share detailed tips in my guide on how to select precise CNC machining materials.

Steel and stainless steel CNC machining

When you need high-strength CNC machined auto components for heavy loads or safety-related parts:

- Carbon steel – Great for structural parts, engine and transmission components, and high-load brackets.

- Stainless steel – Used where corrosion resistance is critical: underbody parts, exhaust-related brackets, coastal use in NL/BE, and all-weather fleet vehicles.

Tool steel, brass and titanium

For specialty or performance builds:

- Tool steel – Wear-resistant parts such as bushings, drive components, and fixtures that must hold tight tolerances over time.

- Brass – Perfect for precision fittings, connectors and custom fluid components in tuning and conversion projects.

- Titanium – Used in high-end motorsport and performance builds where ultra-high strength and minimal weight are key; supported with dedicated 5-axis titanium CNC machining services.

Material selection for EU road conditions

I always pick materials with Benelux use in mind:

- Durability for daily use, fleet vehicles and commercial builds.

- Lightweight design for tuning, EV conversions and racing car components.

- Corrosion resistance against rain, road salt, coastal air and winter road treatments common in the Netherlands and Belgium.

You send the requirements (load, environment, target weight, budget), and I propose the most suitable precision CNC automotive material with clear trade-offs so you can decide fast.

Automotive CNC machining for Netherlands and Belgium

I supply precision CNC automotive parts in the Netherlands and Belgium for a wide range of projects – from daily-driven cars to full race builds. All parts are machined to tight tolerances and tailored to Benelux road and track conditions.

Aftermarket performance & tuning components

For tuners and performance workshops, I machine:

- Custom brackets, flanges, and housings for turbo and supercharger setups

- CNC milled aluminum engine and transmission components for weight reduction

- Precision CNC parts for intake, exhaust, intercooler, and cooling upgrades

If you need repeatable, precision CNC automotive parts in the Netherlands or custom machined auto components in Belgium, I can run both prototype and small series.

Custom builds & specialist conversions

For custom builders and conversion companies in Benelux, I support:

- EV swaps – motor mounts, battery trays, adapter plates, cooling system hardware

- Campervan and overland builds – mounting brackets, hinge components, custom fittings

- Off-road and 4×4 – suspension spacers, reinforcement plates, tow and recovery hardware

I use the same high-precision workflows as our 5-axis CNC machining for complex aluminum parts to keep complex conversion parts accurate and easy to install.

Classic car restoration & low-volume replacements

For classic and youngtimer projects:

- Reverse-engineered brackets, housings, and flanges no longer available from OEM

- Low-volume CNC production for rare or discontinued components

- One-off custom solutions to replace damaged cast or stamped parts

You get prototype CNC auto parts in the Netherlands and Belgium that fit like OEM, with better material and tighter tolerances.

Racing & motorsport CNC parts in Benelux

For racing teams and track-focused workshops across Benelux:

- CNC machined suspension parts, spacers, and link components

- Lightweight aluminum and steel components for engine, drivetrain, and aero hardware

- High-strength CNC turned parts for vehicles where reliability under load is critical

I understand motorsport timelines: parts are delivered fast, consistent, and ready for hard use on Dutch and Belgian circuits.

Quality assurance for CNC automotive machining

When you source precision CNC automotive parts in the Netherlands or Belgium, you can’t compromise on quality. I run our CNC machining for automotive like an OEM supplier, with a strict, ISO-based quality system built for EU road and motorsport conditions.

ISO-based quality control & inspection

We follow ISO-style procedures from RFQ to final delivery:

- Incoming material checks with certificates

- In‑process inspection at critical stages

- Final 100% or sampling inspection (based on your requirements)

- Full measurement reports available on request

Our approach is aligned with our documented ISO-based CNC quality control process, so Dutch and Belgian automotive customers get repeatable, traceable results on every batch.

Tight tolerances down to ±0.01 mm

For performance and safety‑critical components, we routinely machine to tight tolerances:

- Standard automotive parts: IT7–IT9 range

- High-precision features: down to ±0.01 mm

- Complex 5‑axis parts: verified using CMM and calibrated gauges

We also follow internal rules based on recognized CNC machining accuracy standards to keep your parts within spec, batch after batch.

Surface finishing for automotive use

To handle real EU road conditions (salt, rain, track abuse), we offer a full set of finishes for aluminum and steel automotive parts:

- Anodizing (clear, black, colors) for lightweight aluminum brackets and housings

- Powder coating for durable, chip‑resistant exterior parts

- Polishing / brushing for visible performance parts and interiors

- Passivation, plating, hard anodizing on request

You can specify cosmetic and functional requirements so we match both look and durability.

Material traceability & EU compliance

Every batch of custom machined auto components for Belgium and the Netherlands comes with:

- Material certificates (EN standards, heat/batch numbers)

- Process records and inspection data

- RoHS/REACH‑friendly options on request

This gives you traceability from raw material to finished CNC automotive part, and supports compliance with EU automotive and aftermarket requirements for Benelux projects.

Why choose ZSCNC as your custom CNC machining supplier in Netherlands and Belgium

Localised support for Dutch & Belgian automotive companies

I focus on the Benelux market, so I understand how Dutch and Belgian automotive businesses actually work day to day. Whether you’re a tuning shop in Rotterdam, an EV conversion specialist in Antwerp, or a motorsport team in Limburg, you get:

- Dedicated project support for precision CNC automotive parts Netherlands & Belgium

- Clear communication in European business hours

- Parts packed and labelled the way your workshop needs them

If you’re sourcing in China, I also share practical advice on how Dutch and Belgian engineers should choose an aluminum CNC machining supplier based on real projects we run (detailed guide for Benelux buyers).

Fast quotes, short lead times, optimised Benelux shipping

You don’t have time to wait days for a price. For most custom machined auto components Belgium / Netherlands projects:

- Quotes in 24–48 hours once I get your CAD and specs

- Stable lead times for prototype CNC auto parts Netherlands and small batch CNC machining Benelux

- Consolidated shipping routes and packaging designed to cut transit time and damage risk

I know a car stuck on a lift costs money, so I build the schedule around realistic delivery to the Netherlands and Belgium.

Experience with EU automotive and aftermarket rules

I machine parts specifically for EU automotive precision machining needs, including:

- Understanding of common EU aftermarket and road-use requirements

- Material traceability and documentation to support inspections and homologation

- Support for CNC machining for EV conversion parts, tuning parts, and racing components that must meet workshop and track rules

You get parts that don’t just fit—they match typical expectations for the European automotive aftermarket.

Cost-effective pricing & long-term partnerships

My goal is to be your stable CNC machining supplier Netherlands and Belgium, not a one‑off shop. That means:

- Competitive pricing for aluminum CNC parts supplier Europe and steel automotive machining

- Cost-optimised designs through DFM suggestions before we cut metal

- Scalable options: from one‑off prototypes to low-volume CNC production Belgium and ongoing series

- Long-term supply contracts for tuning brands, conversion companies, and distributors

If you need a reliable Benelux CNC machining automotive partner for the next 3–5 years, not just the next order, that’s exactly the relationship I’m set up to support.

For a broader view of what I offer as a China custom CNC machining supplier for overseas buyers, you can check my overview of services and capabilities tailored to European customers (custom CNC machining supplier page).

Step-by-step CNC production process for automotive parts in Netherlands and Belgium

1. Design review & DFM support

When you send us your CAD and specs, we start with a design review and DFM (design for manufacturability) check.

We look at:

- Material choice vs. strength and weight

- Tolerances vs. real machining capability (down to ±0.01 mm where needed)

- Geometry that may need small tweaks to reduce cost or lead time

You get clear feedback so your precision CNC automotive parts for Netherlands and Belgium are right the first time.

2. Rapid prototyping for new automotive components

For prototype CNC auto parts in Netherlands and Belgium, we prioritize speed and consistency:

- Fast machining of 1–10 pcs to validate fit and function

- Same machines and setups we use for series production

- Ideal for tuning parts, EV conversion brackets, and custom housings

This lets Dutch and Belgian workshops test parts on the car quickly before locking in a batch.

3. CNC machining, finishing & assembly

Once the design is confirmed, we move to production:

- 3/4/5-axis CNC milling and CNC turning for complex and round geometry

- Support for tight-tolerance engine, suspension, and chassis parts

- Optional finishing: anodizing, powder coating, polishing, etc.

- Basic sub-assembly if needed (bushes, inserts, simple bolted assemblies)

For complex shapes like multi-face brackets or housings, we rely on our dedicated 5-axis CNC machining services to keep accuracy and repeatability under control.

4. Final inspection, packaging & delivery to Benelux

Every batch of custom machined auto components for Netherlands and Belgium goes through:

- Dimensional inspection vs. drawing

- Visual check after finishing

- Secure, labeled packaging for each part number

- Optimized shipping routes to the Netherlands and Belgium for short lead times

You receive parts ready to install or assemble, with documentation if required.

5. Supported CAD file formats

To keep file handling simple for EU automotive customers, we support:

- STEP (.step, .stp)

- IGES (.iges, .igs)

- SOLIDWORKS (.sldprt, .sldasm)

- Plus other common formats on request

You send your CAD, we handle the rest – from Benelux CNC machining for automotive parts to final delivery at your workshop or warehouse.

Automotive CNC parts gallery and use cases

Example CNC brackets, housings, and flanges for vehicles

I supply precision CNC automotive parts in the Netherlands and Belgium ranging from simple brackets to complex housings and flanges. Typical custom machined auto components include:

- CNC brackets for exhausts, intercoolers, radiators, and sensor mounts

- Custom housings for ECUs, pumps, diffs, and electronic modules

- Flanges and adapters for turbo systems, intake/exhaust, and fluid lines

All parts are machined for exact fitment, clean assembly, and repeatable quality—ideal for performance shops, tuning companies, and specialist workshops across Benelux. For more on what makes good designs work in practice, I recommend checking the CNC machining 101 guide we rely on internally.

Engine, transmission, and suspension parts showcase

For CNC machining for engine components and suspension parts, I handle:

- Engine parts: spacers, sensor bosses, timing covers, brackets, pulley adapters

- Drivetrain: gearbox adapters, shifter components, clutch-related hardware

- Suspension: top mounts, control arm inserts, custom spacers, linkage parts

Most of these are done in aluminum 6061/7075 or high‑strength steel, with tolerances down to ±0.01 mm for critical interfaces. This fits the needs of performance car parts machining and racing car components in Europe.

Real applications in Dutch and Belgian automotive projects

My Benelux CNC machining automotive work is already in use in:

- EV conversions: motor mounts, battery box brackets, inverter plates for Dutch and Belgian EV swap projects

- Campervan and off‑road builds: custom roof rack brackets, suspension spacers, reinforcement plates

- Tuning and racing: turbo flanges, sensor blocks, pedal box parts, lightweight aluminum mounts for track cars

For engineers and builders planning new projects, avoiding common design pitfalls up front saves a lot of time—I break down these issues in detail in our article on top mistakes engineers make when ordering custom CNC parts.

All of these examples show one thing: if you need custom CNC machining supplier for automotive parts in Netherlands and Belgium, I can take you from CAD file to real, track‑ or road‑ready components fast and reliably.

Request a quote for custom CNC automotive parts

If you’re in the Netherlands or Belgium and need precision CNC automotive parts, I keep the quote process simple and fast.

How to submit CAD files and specs

Send me:

- CAD files: STEP, IGES, SOLIDWORKS, or other standard formats

- 2D drawings (if available): with key dimensions and tolerances

- Specs: material, surface finish, quantity (prototype, small batch, or series), target lead time

- Application: engine, suspension, transmission, tuning, EV conversion, etc.

Use the online CNC quote request form to upload your files securely and share all details in one go.

Quote turnaround for Netherlands and Belgium

For Dutch and Belgian projects, I usually respond within:

- 24–48 hours for standard aluminum and steel CNC automotive parts

- A bit longer for complex 5-axis parts or special materials (tool steel, titanium, etc.)

You’ll get clear pricing, lead time, and shipping options optimized for Benelux.

Guidance on materials and tolerances

Not sure which material or tolerance is right? I’ll recommend:

- Materials based on strength, weight, and corrosion resistance for EU road conditions

- Tolerances (down to ±0.01 mm where needed) based on function and cost

- Finishes (anodizing, powder coating, polishing) for durability and appearance

Share your project goals (performance, weight saving, budget), and I’ll help you balance precision CNC automotive parts quality with cost, tailored to the Netherlands and Belgium market.

FAQ – Custom CNC Machining Supplier for Automotive Parts in Netherlands and Belgium

Minimum order quantities (MOQs)

| Type of order | MOQ guideline |

|---|---|

| Prototype CNC auto parts Netherlands | 1–5 pcs (single custom part is possible) |

| Small batch CNC machining Benelux | 10–100 pcs, depending on complexity |

| Medium series for aftermarket suppliers | 100+ pcs with price breaks for higher volumes |

I keep MOQs flexible for tuning shops, racing teams, and custom builders who need low-volume CNC machined components.

Typical lead times for Benelux deliveries

| Service | Typical lead time* |

|---|---|

| Rapid prototype CNC automotive parts | 5–10 working days |

| Small batch / low-volume CNC production Belgium | 10–20 working days |

| Ongoing series for Dutch & Belgian customers | Scheduled / call-off deliveries |

*Lead time depends on material stock, complexity, and finishing.

Material & finishing recommendations for automotive use

Common automotive materials we machine:

- Aluminum (6061, 7075) – lightweight brackets, housings, flanges

- Steel & stainless steel – high-strength engine and suspension parts

- Brass, tool steel, titanium – specialty racing and performance parts

Recommended finishes for EU road conditions:

| Need | Recommended options |

|---|---|

| Corrosion resistance (winter / salt) | Anodizing, hard anodizing, powder coating |

| Visual performance parts | Anodizing (colored), polishing |

| Heavy-duty / off-road | Powder coating, shot blasting + coating |

I help you match materials and finishes to your specific automotive application and EU road conditions.

Design changes, repeat orders & ongoing projects

- Design changes:

- You can update CAD at any stage; I re-check manufacturability and update the quote.

- Repeat orders:

- I store CAM data, setups, and QC reports so repeat runs are faster and more consistent.

- Ongoing projects:

- Long-term aftermarket and racing programs supported with stable pricing, batch scheduling, and tolerance control (down to ±0.01 mm where needed).

If you’re unsure what’s feasible, send your STEP/IGES files and I’ll suggest practical changes to reduce cost while keeping performance.

Dedicated CNC machining support for Dutch and Belgian automotive clients

If you’re in the Netherlands or Belgium and need custom CNC machining for automotive parts, my team and I give you direct, practical support from first contact to final delivery.

Contact options for engineering & procurement

You get fast access to our engineers and project managers for precision CNC automotive parts in the Netherlands and Belgium:

- Engineering teams

- Technical reviews by email or online call

- DFM feedback on complex parts (engine, suspension, housings, brackets)

- Support for prototype CNC auto parts and 5-axis CNC machining for automotive parts

- Procurement & buyers

- Clear, itemized quotes for small batch CNC machining in Benelux

- Long-term pricing options for repeat and series orders

- Help choosing lead times, materials, and finishes that fit your budget and schedule

You can also explore our broader automotive CNC machining services on our dedicated automotive machining page.

Project consultation for CNC automotive parts in Benelux

For Netherlands and Belgium automotive machining projects, I treat every new job like a joint development project:

- One-to-one consultation for aftermarket performance parts, EV conversion components, and custom vehicle builds

- Guidance on material selection (aluminum, steel, stainless, titanium) for EU road conditions and racing use

- Advice on tolerances (down to ±0.01 mm CNC machining) to balance cost, performance, and fit

- Support for low-volume CNC production in Belgium and the Netherlands, from first prototype to stable series

Whether you’re a tuning shop, racing team, converter, or OEM supplier, you get a focused CNC machining partner in Benelux that understands EU automotive precision machining and your day-to-day reality.

Reviews

There are no reviews yet.