POM Engineering Plastic Overview

Discover ZSCNC’s POM plastic: high rigidity, low friction, and exceptional dimensional stability.

Our premium POM polymer offers outstanding wear resistance and structural strength for engineering applications. Learn more about different types of plastic materials and their uses.

POM Material Performance Analysis

High Rigidity and Strength

POM offers superior rigidity and mechanical strength, ideal for demanding industrial applications.

Low Friction and Self Lubrication

Exceptional self-lubricating properties reduce wear and extend component life in moving parts.

Excellent Dimensional Stability

Maintains precise dimensions under varied temperature and humidity, ensuring consistent performance.

Fatigue and Creep Resistance

Resists long-term deformation under constant stress for reliable durability in structural components.

Electrical Insulation Properties

Provides excellent electrical insulation, suitable for electrical and electronic applications. To learn more about different materials, visit our materials page.

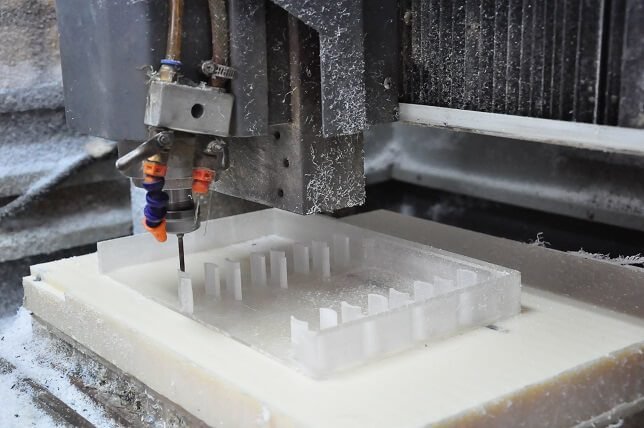

CNC Precision Machining for POM

At ZSCNC, our CNC machining processes optimize POM materials to deliver stable cutting performance and superior dimensional tolerance control.

Stable Cutting Performance

Consistent machining ensures minimal tool wear and smooth cutting with superior surface finish.

Dimensional Tolerance Control

Strict quality checks maintain tight tolerances for high-precision parts meeting rigorous specifications.

Edge and Detail Accuracy

Advanced programming and tooling deliver crisp edges and intricate features without compromise.

Batch Consistency

Repeatable processes guarantee uniform quality across large production runs to support your projects.

POM Application Scenarios

Transmission System Components

Durable POM parts enhance transmission systems with high strength and low friction. Ideal for gears, sprockets, and bearings to ensure smooth, reliable motion.

Guiding and Sliding Parts

POM’s self-lubricating properties reduce wear in guiding and sliding elements. Perfect for linear guides, slides, and conveyors in industrial automation.

Structural Support and Connection Elements

High dimensional stability and mechanical strength make POM ideal for structural supports, fasteners, and connectors in mechanical assemblies. Our services include customized solutions for such industries.

Pump, Valve, and Fluid Parts

Chemical resistance and low moisture absorption make POM suitable for pumps, valves, seals, and other fluid system components requiring durability and precision.

Electrical and Automation Functional Components

POM offers electrical insulation and dimensional accuracy essential for connectors, switches, and functional parts in automation and electrical applications.

When to Prioritize POM Design Considerations

Understanding suitable working conditions ensures optimal performance of POM materials. Selecting the right design parameters minimizes wear, enhances durability, and reduces cost. For more information, visit our about page.

Key Working Conditions for POM

- Moderate temperature range between -40°C and 100°C for dimensional stability

- Exposure to lubricated sliding reduces friction and wear

- Low to moderate chemical exposure with proper sealing

- Load conditions under static and dynamic stresses

Design Selection Guidance

When designing with POM, consider these factors to maximize component life:

- Optimize part geometry to minimize stress concentrations

- Allow for thermal expansion and contraction in tolerances

- Incorporate suitable surface finishes to reduce friction

- Prioritize load distribution for improved mechanical stability

ZSCNC delivers expert guidance to ensure your POM designs meet demanding standards and use cases. For any inquiries, feel free to visit our contact page.

Quality Assurance and Inspection Process for POM Precision Parts

Raw Material Control

We ensure all raw materials meet strict specifications for purity and consistency. This forms the foundation of reliable material control for POM precision parts.

Manufacturing Monitoring

Continuous process monitoring guarantees precision at every step. Our advanced CNC machinery is calibrated to deliver optimal results.

Dimensional and Visual Inspection

Each part undergoes rigorous dimensional checks and visual inspections to maintain tolerance accuracy and flawless surface quality.

Functional Testing (Optional)

Functional testing validates performance under real-world conditions, ensuring your POM components meet all operational requirements.

Customer Customization Process for POM Projects

Needs and Working Condition Communication

We begin every project by understanding your unique application needs and working conditions, ensuring precise customization.

Material and Structural Evaluation

Our experts provide thorough assessments of material properties and structural requirements to optimize performance and durability.

Quotation and Lead Time Confirmation

We deliver transparent quotes and confirm accurate lead times to guarantee smooth project planning and budgeting.

Prototype Trial and Confirmation

We conduct prototype trials with your team to verify specifications, functionality, and quality before full production.

Mass Production and Continuous Improvement

Once approved, we initiate mass production with tight quality control and ongoing refinements for optimal results.

ZSCNC POM Solutions: Industry-Leading Automation & Equipment Manufacturing

At ZSCNC, our engineering philosophy centers on delivering precise, durable POM components tailored for general machinery, light industry, and electrical control systems industry.

Our advanced CNC machining processes ensure consistent quality and efficient automation integration, optimizing performance and reliability in your manufacturing systems. Learn more about our rigorous industry quality control.