Impact-Resistant Easily Formed Engineering Plastic Solutions

Ideal for Impact-Resistant, Dimensionally Stable, Batch-Consistent Components

- Durable Impact-Resistant Structural Parts

- Protective Covers with High Processing Efficiency

- Stable High Batch Production

- Dimensional Stability for Assembly Components

- Secondary Finishing: Painting & Plating

Typical Applications

Instrument housings, Cushioning Structural Parts, Home Appliance Components, Prototype Functional Parts

User Action Support

Small Batch Prototyping, Stable Mass Supply, Quick ABS Suitability Evaluation

ZSCNC delivers engineered ABS precision parts combining durability and dimensional accuracy. Optimize your production with our impact-resistant solutions tailored for consistent quality and finishing.

Material Positioning and Suitable Use Cases

ABS Overview: Balanced Engineering Plastic

ABS offers a unique balance of strength, toughness, and machining efficiency. It is ideal for parts requiring optimized physical performance and cost-effectiveness. For precision manufacturing, CNC machining plays a crucial role in shaping ABS components.

Core Characteristics

- High impact resistance for collision housings and brackets

- Balanced rigidity and toughness to withstand assembly stress

- Dimensional stability minimizing warping at room temperature

- Surface compatibility with painting, silk-screening, and plating

Use Case Cautions

- Avoid exposure to high temperatures and harsh chemicals

- Not suited for extreme mechanical load conditions

- Consult engineering support for design suitability and alternatives involving advanced milling machining processes

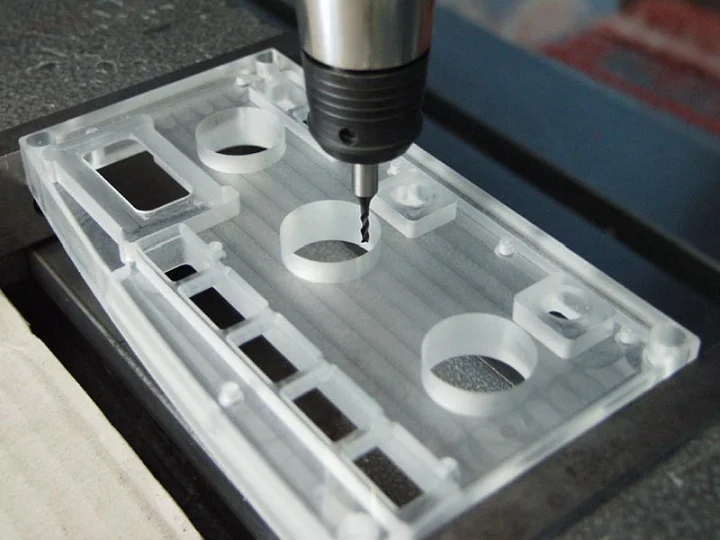

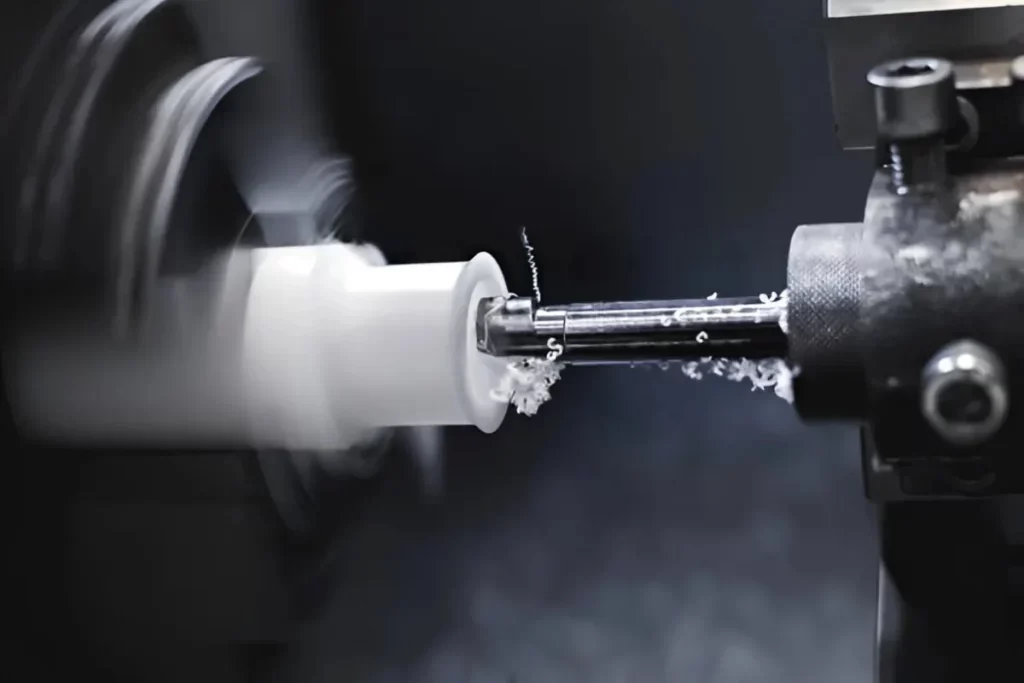

ABS Precision CNC Machining Capabilities and Dimensional Scope

Available Processes

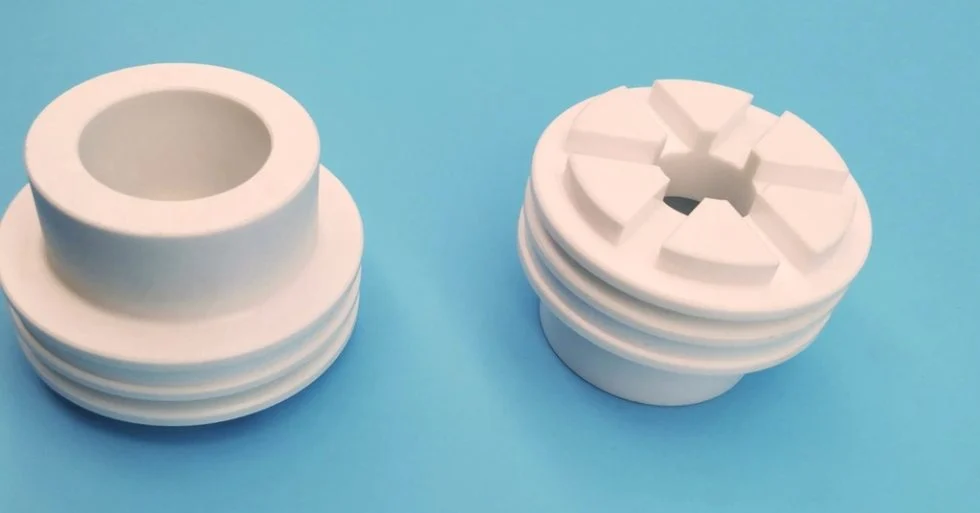

CNC turning, milling, and complex multi-axis machining support parts ranging from simple to curved cavity components.

Dimension and Precision

Precision ensured from small precision parts to medium structural components via fixture design and strategic machining.

Surface Quality and Edge Control

Toolpath optimization minimizes burrs and chipping, delivering stable detail reproduction including snap fits and locator bosses.

Batch and Delivery Support

Adaptable workflow reduces lead times for prototypes, small batch trials, and mass production runs.

Mechanical and Performance Characteristics

Strength and Rigidity

Suitable for medium strength supports, clamps, and structural connectors. Engineered for optimal strength while remaining cost efficient.

Impact Resistance and Toughness

Designed for robust use in transport, installation, and protective enclosing cushion applications. Ensures durability under harsh conditions.

Dimensional Stability and Thermal Behavior

Maintains consistent dimensions at ambient conditions. Perfect for precise mating components requiring tight tolerances.

Electrical and Insulating Properties

Ideal for electrical housings and covers in non-extreme insulation scenarios, balancing performance with safety.

Material Selection Recommendations

Our recommended material balances strength, cost efficiency, and impact resistance to meet varied engineering requirements.

Surface Finishing and Aesthetic Enhancement Options

Supported Finishing Technologies

- Painting with durable brand colors: matte, gloss, silk-screening

- Marking logos and instructions with precision laser techniques

- Electroplating to achieve premium metal appearance

- Decorative accents enhancing visual appeal

Surface Texture and Feel

- Smooth surfaces ensuring elegant appearance and easy cleaning

- Fine matte textures reducing glare and enhancing experience

- Grip enhancing patterns improving handling and user safety

- Scratch resistance for lasting product quality and aesthetics

Design for Assembly and Appearance

- Collaborative design process aligning aesthetics with assembly

- Ensuring precision to prevent rework and reduce costs

- Optimizing component fit for seamless integration

- Enhancing overall product appearance and durability through sheet-metal fabrication

Typical Application Industries & Part Examples

Electronics and Electrical

Protective casings, terminal covers, and internal brackets designed to enhance safety and appearance.

Industrial Mechanical Structures

Lightweight supports, baffles, and cushion pads that reduce weight while maintaining rigidity and strength.

Home Appliances & Consumer Goods

Panel frames, internal supports, and mounting clips engineered for impact resistance and mass production compatibility in home products.

Prototypes & Functional Samples

Structural moving parts designed for rapid iteration and functional verification during development phases.

Project Collaboration Workflow & Quality Assurance

Project Intake and Specification

- ABS Material Designation for optimal durability and versatility

- Key Dimensions aligned with client requirements

- Operating Environment considerations for performance stability

- Estimated Production Volumes tailored for cost efficiency

Manufacturing Feasibility & Process Advice

- Wall Thickness, Chamfer, and Hole Structure analysis for durability

- Optimization of Assembly Interfaces for ease and stability

- Recommendations for Structural Stability and Cost Efficiency

Sample Production and Validation

- Rapid Prototyping to verify function and assembly

- Appearance and Performance Checks aligned with specs

- Functional Assembly testing to ensure reliability

Mass Production and Quality Control

- Dimensional and Visual Inspection checkpoints for batch consistency

- Strict Quality Control aligning with project and client standards

- Traceability and comprehensive Documentation for full transparency

Continuous Improvement & Project Tracking

At ZSCNC, we ensure ongoing project tracking, continuous improvement, and rigorous inspection data management. Our dedicated teams deliver consistent quality while adapting to evolving client requirements. Ensuring the right materials are used is essential for this process.