Precise CNC Machining Solutions for Plastic Materials

Multi-variety engineering plastics designed to meet varied mechanical requirements. Supporting both small-batch and mass precision processing.

Plastic Categories & Applications:

- CNC Engineering Plastics: Structural, Protective, Functional Parts

- Suitable for Lightweight, Wear Resistant, Electrical Insulation

- Harsh Chemical Environments Compatibility

Lightweight Design Support

Solutions optimized for reducing part weight without compromising strength.

Versatile Mechanical Property Combinations

Customizable properties to fit precise performance requirements for your application.

Precision Dimensional Control

Tight tolerance control for complex geometries and consistent part quality.

Adapted for Global Market Use

Compliant with international standards for global distribution and performance.

Positioning and Applications of Plastic Materials in Precision CNC Machining

Material Positioning

- Plastics excel in weight sensitivity, offering significant weight reduction over metals.

- Outstanding electrical insulation properties for safe, durable components.

- Superior corrosion resistance ensures longevity in harsh environments.

- Effective noise reduction capabilities enhance operational comfort.

- Advantages over metals include light weight, insulation, and chemical resistance.

Typical Applications

Automation Components

Guide rails, sliders, and buffers optimize automated system performance.

Medical Industry Parts

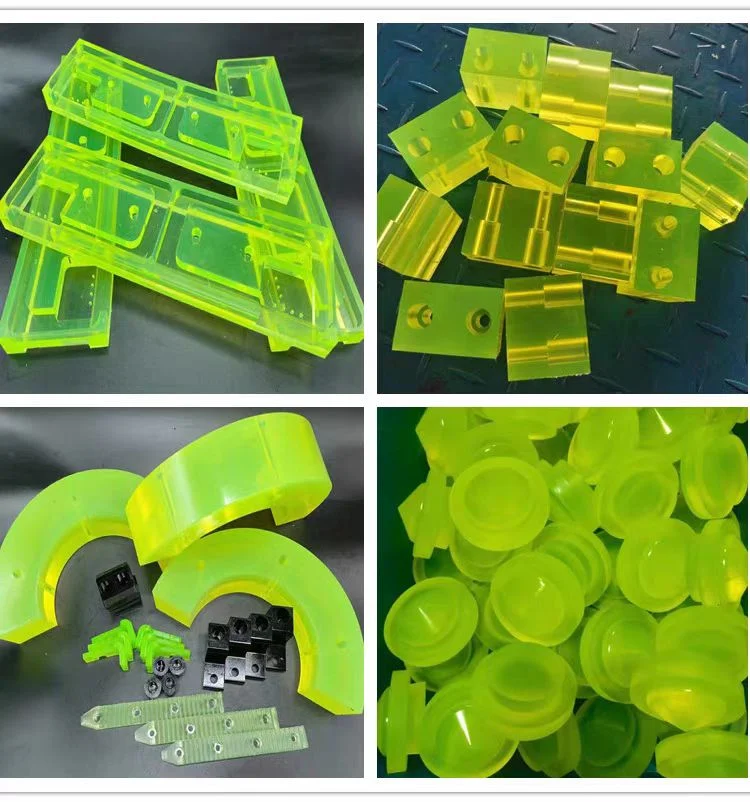

Transparent observation parts support precision and hygiene standards.

Support Structures

Lightweight and insulating brackets, housings, and support components.

Electronics

Insulating brackets and housings ensure electrical safety and durability.

Light-load Transmission

Gears, couplings, and pulleys designed for efficient power transfer.

Integration with ZSCNC Services

ZSCNC offers comprehensive support from custom precision turning, milling, drilling, tapping to batch manufacturing.

Our CNC machining services enable seamless trial production through scalable processes for consistent quality and efficiency.

Plastic Material Performance Dimensions Explained

Mechanical Performance

- Impact Resistance: Ability to withstand sudden forces without fracturing.

- Rigidity: Resistance to deformation under load.

- Wear Resistance: Durability against abrasion and surface damage.

Environmental Tolerance

- Temperature Resistance: Functionality in extreme hot or cold conditions.

- Chemical & Moisture Resistance: Stability when exposed to solvents and humidity.

- UV Resistance: Sustained performance under ultraviolet exposure.

- Corrosion & Cleaning: Suitability for harsh cleaning regimes and corrosive environments.

Functional Features

- Transparency: Clarity options impacting visual and light transmission.

- Low Friction & Self-lubrication: Reduced wear and smoother movement in applications.

- Non-stick Surfaces: Minimizing adhesion for ease of cleaning and material flow.

- Electrical Insulation: Safety and performance in electronic applications.

- Dimensional Stability: Resistance to shrinkage or expansion for precision parts.

Machining and Tolerance

Different plastics require tailored tooling, cooling, and adjusted parameters to control deformation and achieve dimensional precision. Our expertise in CNC machining ensures tight tolerances for high-quality components.

Understanding these factors ensures tight tolerances for high-quality components critical in demanding applications.

Plastic Material Categories Selection Guidance by Application Needs

Structural Load-bearing Materials

Choose plastics that ensure rigidity, strength, and dimensional stability. Ideal for supports, connectors, and light mechanical structures requiring reliable load-bearing capacity. To complement plastic parts, metal fabrication often provides robust integration options.

Appearance Visualization Materials

Plastics selected for optics, surface finishes, and internal visibility enhance product aesthetics and functionality. Optimize materials for clarity and scratch resistance.

Friction Motion Pairing Materials

Select plastics optimized for sliding fits, rotary components, and low-noise motion. Provides plastic alternatives to metal to reduce wear and ensure smooth mechanical operation.

Temperature and Media Resistance

Use high-performance plastics resistant to high temperatures, chemicals, aggressive media, and sanitation environments. Crucial for durability and safety under harsh conditions.

Expert Guidance for Material Selection

Leverage professional advice based on drawings and working conditions to avoid mismatched material selections. Ensure optimal performance and longevity with ZSCNC’s expertise.

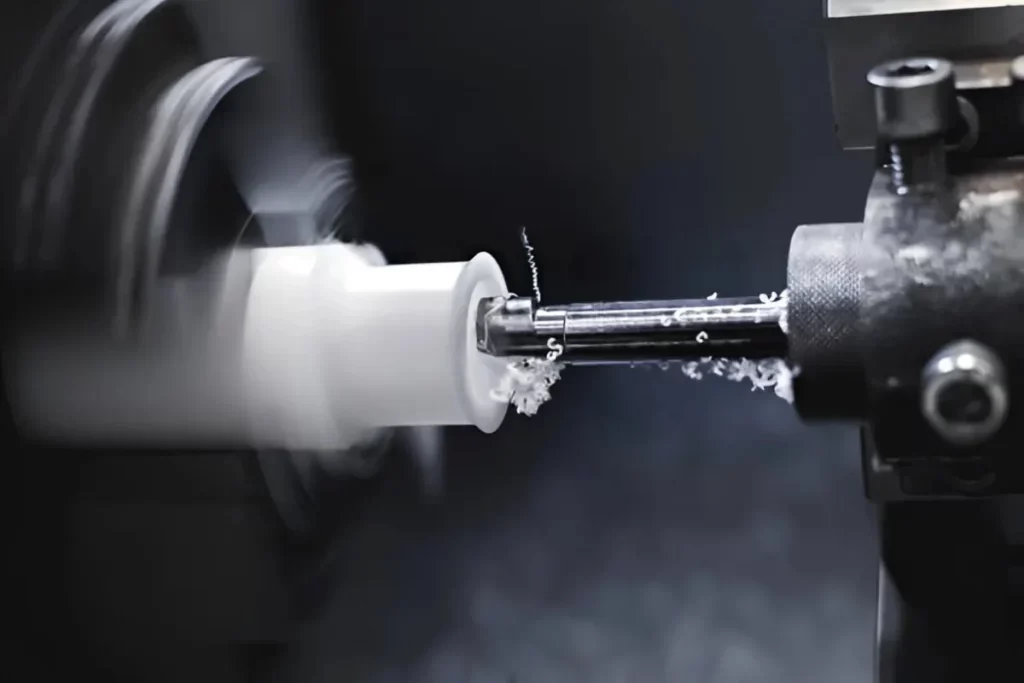

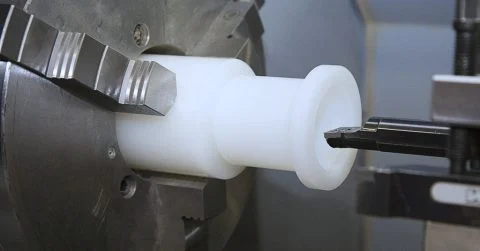

CNC Machining Capabilities for Precision Plastic Components

Advanced Equipment & Machining Scope

ZSCNC leverages precision turning, 3 to 5 axis milling, drilling, tapping, chamfering, and complex contouring.

Tailored exclusively for plastic materials, we ensure sharp tool control, optimal cutting speeds, and clamping strategies to minimize heat deformation and burrs.

Unmatched Process Control & Quality

Our strict surface quality management guarantees dimensional accuracy, tolerance fit, flatness, concentricity, and stress relief.

Cooling and finishing processes meet all assembly fit and aesthetic standards, supporting flawless integration into your product designs enhanced by our advanced CNC machining technology.

Flexible Production & Prototyping

ZSCNC supports small-batch prototyping, R&D pilot runs, single-piece proofs, volume production, and mass manufacturing, utilizing specialized five-axis CNC machining for complex components.

Our processes scale with your needs, combining precision and repeatability for every piece.

Plastic Part Quality Inspection & Compliance

Precision Inspection & Dimensional Verification

ZSCNC uses advanced gauges, fixtures, projection, and vision measuring systems. We ensure critical sizes and dimensions meet stringent international standards.

- Defect inspection for burrs, scratches, stress cracks, and deformation

- Batch labeling, parameter logging, and sample preservation for traceability

International Market Compliance & Documentation

We support seamless supply chain integration with clear marking, protective packaging, material certificates, and detailed inspection reports.

Sustainable Cooperation & Stable Quality

Ongoing communication and quality stability empower repeat usage of plastic solutions made with premium materials, reducing customer R&D validation cycles and enhancing efficiency.

Customized Plastic Material Selection Consultation Workflow

1. Requirement Gathering

- Analyze operating environment and temperature conditions

- Identify media exposure and load requirements

- Determine expected lifespan and target cost

2. Material & Process Recommendations

- Suggest materials based on strength, wear, and transparency

- Ensure chemical compatibility with operating media, leveraging our CNC machining services

- Plan processes for precision and accuracy

3. Sampling & Validation

- Prototype production and dimensional assembly using our milling services

- Perform real-world testing and gather feedback

- Fine-tune materials and structures for optimal performance

4. Long-Term Supply & Change Management

Ensure consistent quality through supply cycles with rigorous change control and production scheduling, supported by our comprehensive services.

Manage packaging and production changes proactively to maintain material integrity and delivery timelines.