Copper Material Performance Overview

Discover ZSCNC’s expert copper machining solutions. Superior conductivity, corrosion resistance, and precision performance tailored for semiconductor and industrial applications.

Copper Alloy Grades & Material Specifications

Explore ZSCNC’s comprehensive range of copper alloy grades formulated for precision machining and high-performance applications. Our materials meet strict specifications ensuring reliability, durability, and optimal conductivity.

-

High Conductivity Copper Alloys

Ideal for electrical and thermal applications, offering superior conductivity and corrosion resistance.

-

Beryllium Copper (BeCu)

Known for outstanding strength, fatigue resistance, and excellent machinability in critical components.

-

Brass and Bronze Grades

Versatile alloys balancing strength and formability for seals, bushings, and precision parts.

-

Standard Compliance

Materials adhere to ASTM, DIN, and ISO standards, ensuring consistent quality and traceability.

Why Choose ZSCNC Copper Alloys?

Precision & Quality

Strict quality control guarantees dimensional accuracy and consistent alloy properties.

Wide Specification Range

From low to high alloy content, tailor materials to your exact material performance needs.

Industry Standards Compliance

Our products meet ASTM, DIN, and ISO certifications for industrial and commercial use.

Copper Precision Machining Capabilities & Structural Features

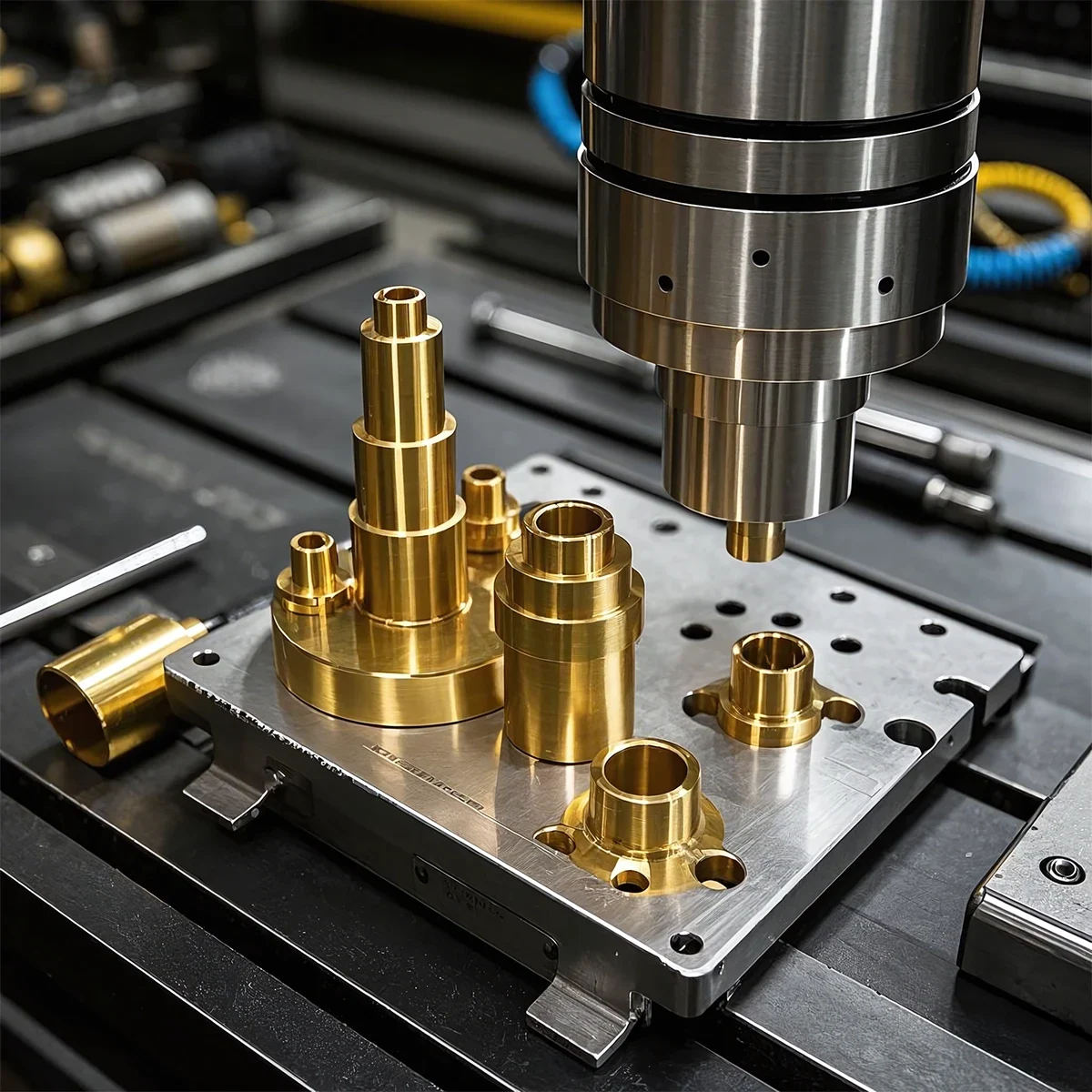

High-Precision CNC Machining

ZSCNC delivers tight-tolerance machining for copper components, ensuring dimensional accuracy up to ±0.01 mm.

Advanced Structural Stability

Our copper parts feature enhanced structural integrity suitable for high-stress industrial applications.

Superior Surface Finishes

We utilize state-of-the-art polishing to achieve smooth, corrosion-resistant copper surfaces.

Precision Connectors

Machined copper connectors for reliable electrical and mechanical performance.

Complex Geometries

Capability to machine complex copper alloy shapes with exact specifications.

Scalability & Efficiency

Streamlined production lines achieve high throughput without compromising quality.

Typical Copper Applications in Electrical and Thermal Management

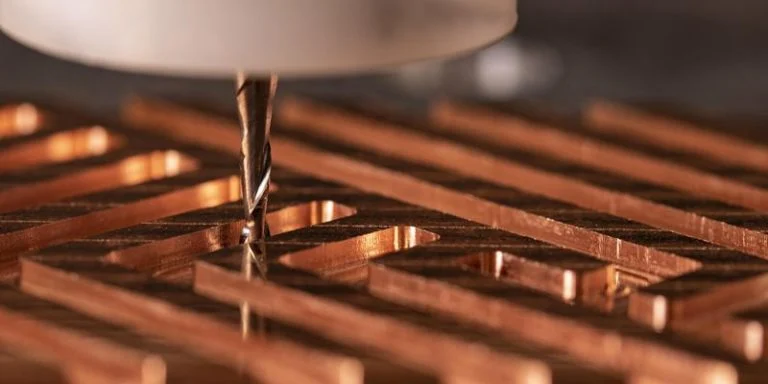

Precision CNC Machined Copper Components

High-precision copper parts ensure optimal electrical conductivity for industrial and electronic applications. CNC machining guarantees consistent accuracy and surface finish. Learn more on our about page.

Copper Alloy Die Casting for Durable Parts

Copper alloys are ideal for non-standard die casting parts used in automotive and machinery sectors, offering superior thermal management and corrosion resistance.

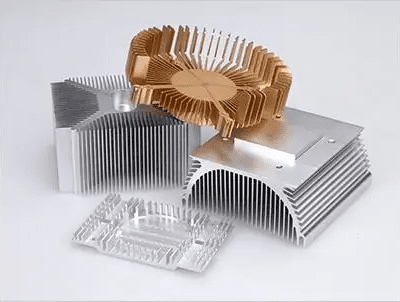

Thermal Management Solutions

Copper’s high thermal conductivity supports effective heat dissipation in electrical devices and power systems, improving reliability and lifespan. For inquiries, please visit our contact page.

Custom Copper Alloys

Tailored copper alloys for specialized electrical and mechanical requirements.

CNC Machined Copper Parts

Precision machining ensures tight tolerances and superior electrical contact.

Thermal Components

Engineered copper components for effective heat conduction and management.

Copper Surface Treatment and Performance Enhancement Solutions

ZSCNC offers advanced copper treatment processes that improve durability, conductivity, and corrosion resistance. Discover our solutions tailored for your industry.

Precision Surface Finishing

Our treatments enhance surface smoothness and dimensional accuracy, ensuring optimal conductivity for copper components.

Corrosion and Wear Resistance

Specialized coatings and chemical processes protect copper parts, extending product lifespan in demanding environments.

Custom Solutions for Industry Needs

ZSCNC tailors surface treatment methods to meet your specific performance requirements and manufacturing standards in various industries.

Quality Control and International Supply Stability for Copper Projects

At ZSCNC, we ensure rigorous quality control at every production stage. Our copper projects meet international standards, guaranteeing superior material integrity and durability.

Our streamlined international supply chain provides stability and timely delivery, reducing risk and supporting your global operations with consistent copper product availability.

Leveraging advanced CNC machining and precision manufacturing techniques, ZSCNC drives efficiency while maintaining strict compliance and performance benchmarks.