Titanium 5-Axis CNC Machining Services Overview

When you’re dealing with titanium, you can’t afford guesswork. Our titanium 5-axis CNC machining services are built for parts that are high-value, high-risk, and mission-critical.

We use simultaneous 5-axis titanium milling and turning to machine complex components in a single setup, holding tight tolerances on custom titanium CNC parts while keeping lead times under control.

What Our Titanium 5-Axis CNC Machining Services Include

Our titanium CNC machining service covers the full scope of precision titanium machining:

- 5-axis titanium milling and turning for complex, multi-sided parts

- Machining of Ti-6Al-4V (Grade 5), Grade 23, and other titanium alloys

- Tight tolerance titanium parts (up to ±0.005 mm / ±0.01 mm, where feasible)

- Complete setups for complex titanium geometries, undercuts, and deep cavities

- CNC programming, fixture design, and process optimization for titanium

- Small-batch titanium prototype machining and low-volume titanium production

Who These Services Are For

Our titanium alloy CNC services are aimed at teams who need reliable, production-grade results:

- Design engineers needing 5-axis titanium milling for complex 3D shapes

- Buyers and supply chain teams sourcing precision titanium machining globally

- Product designers working on lightweight, high-performance titanium components

- Aerospace, medical, motorsport, defense, and energy manufacturers

If your part is expensive to fail, we design the process to protect you.

Key Benefits of 5-Axis Machining for Titanium Parts

Choosing multi-axis titanium machining over conventional setups delivers real advantages:

- Fewer setups, fewer errors – 5-axis machining hits more features in one clamping

- Better accuracy – reduced stack-up errors for tight tolerance titanium parts

- Superior surface finish – consistent tool engagement on complex contours

- Access to hard-to-reach features – channels, pockets, and organic surfaces

- Shorter lead times – optimized toolpaths and less manual handling

For aerospace titanium machining and medical titanium machining services, these benefits translate directly into higher-quality and more consistent parts.

5-Axis vs 3-Axis for Complex Titanium Components

For simple prismatic parts, 3-axis can still work. But for high-value titanium parts, 5-axis titanium milling is usually the smarter choice:

| Requirement | 3-Axis Machining | 5-Axis Titanium Machining |

|---|---|---|

| Complex freeform surfaces | Difficult, multiple setups | Efficient and precise |

| Tight positional tolerances | Higher risk of stack-up error | Better accuracy, one setup |

| Undercuts and deep pockets | Often impossible or costly | Accessible and controllable |

| Surface finish on curved features | Compromised tool angles | Optimized tool orientation |

If your drawing has multiple angles, compound features, or GD&T on multiple datums, 5-axis titanium CNC machining is almost always the better fit.

When to Choose Titanium 5-Axis CNC Machining

You should consider advanced titanium CNC manufacturing with 5-axis capability when:

- The part is complex, asymmetric, or highly contoured

- You need tight tolerance titanium parts and repeatable quality

- Material is Ti-6Al-4V CNC machining or other hard titanium alloys

- Applications are aerospace, medical implants, motorsport, or defense

- Additive or casting can’t meet the dimensional accuracy or surface finish required

In short, when the part is critical, the geometry is complex, and titanium is non-negotiable, titanium 5-axis CNC machining services are the process you can rely on.

Why Use Titanium for CNC Machined Parts

For demanding projects, titanium is often the smartest move for precision titanium machining and 5-axis titanium milling. When weight, strength, and reliability actually matter, titanium 5-axis CNC machining services give you a real edge.

Strength-to-Weight: Maximum Performance, Minimum Mass

Titanium has an outstanding strength-to-weight ratio—strong like steel, but much lighter. That’s a big win for:

- Aerospace: brackets, mounts, structural parts where every gram counts

- Motorsport & performance automotive: high-stress, lightweight titanium components

- Robotics & consumer products: stiff, light parts that can still take a beating

You get rigid, high-strength custom titanium CNC parts without the weight penalty of stainless steel.

Corrosion Resistance in Harsh Environments

Titanium naturally forms a stable oxide layer, making it extremely corrosion-resistant, even in:

- Saltwater and marine environments

- Chemical processing and offshore applications

- Medical and body-fluid exposure

If you need long-life, corrosion-resistant titanium parts with minimal maintenance, titanium beats aluminum and many steels by a mile.

High-Temperature Performance

Titanium alloys like Ti-6Al-4V (Grade 5) stay strong at elevated temperatures, which is critical for:

- Aerospace titanium machining: turbine-related parts, engine brackets

- Automotive and motorsport: exhaust, valves, heat-exposed hardware

- Energy and industrial: hot gas, high-temp structural components

Where aluminum softens and some steels creep, titanium keeps its shape and strength.

Biocompatibility for Medical and Implants

Titanium is one of the most widely used materials for biocompatible titanium components:

- Orthopedic and dental implants

- Surgical instruments and fixtures

- Patient-specific, custom titanium CNC parts

Alloys like Ti-6Al-4V ELI (Grade 23) are standard in CNC machining for titanium implants because they’re safe in the body and integrate well with bone.

Dimensional Stability & Low Thermal Expansion

Titanium’s relatively low thermal expansion and high stability make it ideal for:

- Precision assemblies and instrument housings

- Optics mounts, measurement tools, and control hardware

- Tight tolerance titanium parts that must hold spec across temperature swings

You get better long-term accuracy and fewer thermal distortion issues compared to aluminum.

Titanium vs Aluminum, Stainless Steel, or Inconel

Here’s when titanium is usually the right call:

- Choose titanium over aluminum when you need:

- Higher strength at the same or lower weight

- Much better corrosion resistance

- Higher temperature capability

- Choose titanium over stainless steel when you need:

- Similar or better strength at much lower weight

- Superior fatigue and corrosion performance

- Choose titanium over Inconel when you need:

- High strength and heat resistance, but lighter

- Better weight savings with still excellent durability

If your project requires a combination of lightweight, high strength, corrosion resistance, and temperature performance, titanium alloy CNC services are usually the best fit. For more details on specific grades and options, you can check our dedicated titanium CNC material capabilities.

Titanium 5-Axis CNC Machining Capabilities

Simultaneous 5-axis titanium milling and turning

With our titanium 5-axis CNC machining services, we run true simultaneous 5-axis milling and mill-turn on titanium alloys (including Ti-6Al-4V / Grade 5). This lets us:

- Machine multiple faces in one clamp

- Keep features perfectly aligned

- Cut cycle time and stack-up error for tight tolerance titanium parts

Complex geometries and undercuts in one setup

We use multi-axis titanium machining to reach deep pockets, undercuts, and side features without extra fixtures. That means:

- Better accuracy on complex titanium geometries

- Fewer setups and lower risk of distortion

- Cleaner features for blisks, impellers, brackets, and organic shapes

Titanium part size and machining envelope

For 5-axis titanium milling and turning, we typically support:

- 5-axis milling envelope: up to ~Ø500 mm x 400 mm height (project-dependent)

- Mill-turn envelope: up to ~Ø250 mm x 600 mm length

If you’re unsure your part fits, send the STEP file and we’ll confirm fit and best process.

Pockets, channels, and organic shapes

Our precision titanium machining handles:

- Deep pockets and cooling channels

- Thin ribs and lightweight structures

- Freeform and organic 3D surfaces

We focus on rigidity and path optimization so thin-wall titanium alloy CNC parts don’t chatter, warp, or burn.

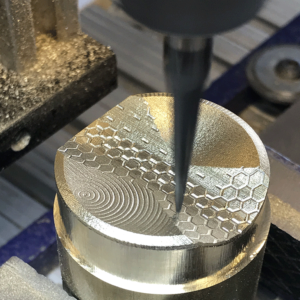

Automated toolpath strategies for titanium

For advanced titanium CNC manufacturing, we rely on proven CAM strategies:

- High-efficiency roughing for stable chip load and lower heat

- Smooth 5-axis finishing passes for Ra 0.8–0.4 μm where needed

- Adaptive stepdowns and constant engagement to extend tool life

This keeps Ti-6Al-4V CNC machining efficient, stable, and repeatable from prototype to production.

Chip management and coolant for titanium

Titanium hates heat, so our setups focus on control:

- High-pressure, through-tool coolant on critical operations

- Aggressive chip evacuation from deep pockets and small slots

- Coolant selection that improves surface integrity and tool life

This is how we keep edges sharp, avoid work hardening, and deliver reliable titanium CNC machining services for global aerospace, medical, and industrial customers.

Supported Titanium Grades and Alloys for 5-Axis CNC Machining

Commercially Pure Titanium (Grade 1–4)

For titanium 5-axis CNC machining services, I regularly work with commercially pure (CP) titanium Grades 1–4 when customers need excellent corrosion resistance, high ductility, and good formability more than maximum strength.

- Grade 1 & 2: Great for chemical equipment, medical instruments, low-stress aerospace and marine parts. Easier to machine than high-strength alloys, so cycle times and tool wear are more manageable.

- Grade 3 & 4: Higher strength CP titanium for slightly more demanding structural or pressure applications, with a bit more machining difficulty but still workable on 5-axis.

Ti-6Al-4V (Grade 5) – The Workhorse Alloy

Ti-6Al-4V (Grade 5) is the most requested alloy in our titanium CNC machining service. It offers a very strong combination of strength, weight, fatigue resistance, and temperature performance, making it the default choice for:

- Aerospace brackets, housings, and structural parts

- High-performance automotive and motorsport components

- High-load, lightweight mechanical parts with complex geometries

It is tougher to cut than CP titanium, so we optimize feeds, speeds, and tool paths to keep tool wear and cost under control while holding tight tolerances.

Ti-6Al-4V ELI (Grade 23) – For Implants and Critical Components

For medical titanium machining services and very critical aerospace parts, I often recommend Ti-6Al-4V ELI (Grade 23). It has lower impurity content than standard Grade 5, giving:

- Better fracture toughness and fatigue performance

- Excellent biocompatibility for implants and patient-specific devices

- Reliable performance in highly stressed, safety-critical parts

This alloy is slightly more challenging and costly to machine, but for implants and life-critical components, the material properties justify it.

Other Titanium Alloys (Grade 9, Grade 12, and More)

Beyond the common grades, I can support other titanium alloys on request, such as:

- Grade 9 (Ti-3Al-2.5V): Great for tubing, bike frames, and lightweight structural parts where formability and strength must be balanced.

- Grade 12: Strong corrosion resistance in hot, mildly reducing environments; common in chemical and marine systems.

If you’re not sure which alloy fits your application, my team can help select the best option based on strength, corrosion, formability, and budget. For more background on picking the right metal, you can check our guide on how to select precise CNC machining materials.

Choosing the Right Titanium Grade

When we recommend a titanium grade for precision titanium machining, we usually balance these factors:

- Strength & fatigue: Grade 5 / 23 for high-load structural and rotating parts

- Corrosion resistance: CP Grades 2–4 and Grade 12 for marine and chemical environments

- Biocompatibility: Grade 2 and Grade 23 for implants and medical devices

- Formability vs machinability: Grade 9 and CP grades when forming and bending are required

- Cost vs performance: CP grades are cheaper and easier to machine; high-alloy grades cost more in both material and machining time

How Alloy Choice Affects Machining Time, Cost, and Tool Wear

Not all titanium machines the same. For multi-axis titanium machining, alloy selection has a direct impact on:

- Cycle time: Harder, stronger alloys (Grade 5, 23) require lower cutting speeds and more conservative toolpaths.

- Tool wear: High-strength alloys wear tools faster, especially in deep pockets, 5-axis contours, and long engagement cuts.

- Part cost: More tool changes + slower cutting + more complex strategies = higher per-part price. CP titanium and Grade 9 often run faster and cheaper.

When you share your 3D models and requirements, I’ll usually propose both a material option and a machining strategy that keeps your titanium 5-axis CNC machining services project within budget while meeting performance and certification needs.

Precision, Tolerances, and Surface Finish for Titanium 5-Axis CNC Machining

When you need tight tolerance titanium parts, 5-axis CNC is the way to go. On our titanium 5-axis CNC machining services, we routinely hold standard tolerances of ±0.01 mm, and for critical features we can go down to ±0.005 mm on request, depending on geometry and setup. For a more detailed breakdown of our default and achievable tolerances, you can check our standard tolerances for 5-axis parts.

Tight tolerances on complex titanium parts

On precision titanium machining projects, we control:

- Flatness on reference faces

- Roundness on bores, journals, and shafts

- True position of holes, slots, and datums for assemblies

- Profile tolerances on complex 5-axis surfaces

With proper fixturing and toolpaths, we keep these in spec even on multi-axis titanium milling jobs with deep features and multi-sided machining.

Surface finish for titanium components

For critical sealing, bearing, and medical surfaces, we can deliver:

- Functional surfaces: Ra 1.6–0.8 μm (standard)

- High-end finishes: Ra 0.4 μm or better in key areas

- As-machined cosmetic surfaces suitable for many aerospace and automotive parts

Surface finish always depends on tool selection, step-over, toolpath strategy, and titanium grade, but we tune these for each project.

How geometry affects tolerance and finish

On titanium alloy CNC services, part design drives what’s realistic:

- Thin walls and long overhangs are more prone to chatter and deflection

- Deep pockets and narrow channels may limit tool access and finishing quality

- Very small radii and micro-features can push cycle time and tool wear up

We’ll usually review your model and flag areas where relaxing a tolerance or changing a radius will reduce risk and cost.

Inspection tools for titanium 5-axis parts

To verify tight tolerance titanium parts, we use:

- CMM (Coordinate Measuring Machines) for complex 3D surfaces and GD&T

- Optical measurement systems for small features and profiles

- Pin gauges, micrometers, bore gauges, and height gauges for key dimensions

Measurement reports and full traceability are available when needed (aerospace, medical, defense).

Design tips to balance precision, cost, and lead time

To keep titanium 5-axis machining efficient and affordable:

- Hold tight tolerances only where function demands it

- Use consistent datums and clear GD&T on drawings

- Avoid unnecessary ultra-fine surface finishes on non-critical faces

- Add generous radii in pockets and internal corners when possible

- Talk to us early for titanium machining DFM support so we can suggest cost-saving tweaks

This approach gives you reliable, repeatable precision titanium machining without blowing up your budget or lead time.

Industries Using Titanium 5-Axis CNC Machining

Our titanium 5-axis CNC machining services are built for teams who can’t compromise on strength, weight, or reliability. We support global customers across aerospace, medical, automotive, defense, energy, robotics, and premium consumer products with precision titanium machining and repeatable quality.

Aerospace Titanium 5-Axis CNC Machining

For aerospace, we machine complex titanium parts like:

- Turbine blades, blisks, and impellers

- Structural brackets, ribs, and hardpoints

- Housings, mounts, and lightweight frames

5-axis titanium milling lets us handle complex aerodynamics, deep pockets, and tight tolerance titanium parts in one setup, ideal for weight-critical and high-temperature components in flight hardware and engines.

Medical & Dental Titanium Machining Services

We provide medical titanium machining services for:

- Custom and standard implants (Ti-6Al-4V, Ti-6Al-4V ELI)

- Surgical instruments and dental tools

- Patient-specific guides and fixtures

Biocompatible titanium components demand ultra-clean machining, traceable materials, and consistent surface finish. We focus on smooth contours, burr-free edges, and documented quality for implants and instruments.

Automotive & Motorsport Titanium CNC Parts

For performance vehicles and motorsport, we machine:

- Valves, fasteners, and connecting elements

- Lightweight brackets, mounts, and suspension parts

- Heat-resistant components for powertrain and exhaust

Titanium 5-axis CNC machining lets us reduce weight without sacrificing strength, ideal for racing teams and OEMs pushing for better power-to-weight and higher reliability under extreme conditions.

Defense, Marine & Energy Titanium Components

Defense, marine, and energy projects rely on:

- Corrosion-resistant titanium hardware and fittings

- Structural and pressure components

- High-temperature and high-stress parts

These sectors often need full traceability, export control compliance, and robust quality control. For energy projects, we combine titanium 5-axis CNC machining with our experience in demanding environments similar to those in our energy industry machining services.

Industrial, Robotics & High-Performance Products

We also deliver custom titanium CNC parts for:

- Robotics arms, joints, and precision frames

- Industrial automation components and end effectors

- High-end consumer products, sports gear, and electronics housings

Here, the focus is usually on a balance of strength, weight, appearance, and cost. Our multi-axis titanium machining and general CNC machining capabilities help teams move quickly from titanium prototype machining to stable low-volume production.

Different Requirements by Industry

Each industry comes with its own priorities:

- Aerospace & defense: Tight tolerances, full documentation, certifications, and long-term repeatability.

- Medical: Biocompatibility, surface integrity, cleanliness, and strict traceability.

- Automotive & motorsport: Performance, weight reduction, and fast turnaround.

- Energy & marine: Corrosion resistance and durability in harsh environments.

- Robotics & consumer: Precision, aesthetics, and cost-effective low-volume titanium production.

We tune our titanium 5-axis CNC machining process to match your sector’s standards, whether you need one-off prototypes or ongoing production of complex titanium geometries.

Typical Titanium 5-Axis CNC Applications

Our titanium 5-axis CNC machining services are built for parts that are light, strong, and complex. Here’s where they shine in real projects:

Complex titanium brackets and structural components

We machine complex titanium brackets, ribs, and structural links in a single setup, keeping weight low and strength high. 5-axis machining lets us hit multiple faces, blend radii, and maintain tight tolerance titanium parts for load‑bearing aerospace, motorsport, and robotics assemblies.

Impellers, blisks, and turbine titanium parts

For impellers, blisks, and other turbine-related titanium components, simultaneous 5-axis titanium milling is essential. We manage deep blades, twisted profiles, and smooth transitions, delivering high-temperature titanium components that run efficiently in engines, pumps, and compressors.

Lightweight titanium frames, mounts, and enclosures

We produce lightweight titanium frames, mounts, housings, and enclosures where stiffness, durability, and corrosion resistance matter. Multi-axis machining allows for integrated features—bosses, pockets, and channels—without extra joints or welds, ideal for aerospace titanium machining and rugged industrial gear.

Custom titanium implants and patient-specific devices

With medical titanium machining services, we handle CNC machining for titanium implants, plates, and patient-specific parts in Grade 5 and Grade 23. 5-axis capability is key for organic shapes, smooth contours, and precise interfaces needed for biocompatible titanium components that meet strict quality and traceability standards backed by our CMM-based quality control process.

Heat-resistant titanium hardware and fasteners

We machine heat-resistant titanium fasteners, bolts, fittings, and hardware that must survive high loads and high temperatures. Our precision titanium machining keeps threads, seating faces, and bearing surfaces accurate so assemblies stay tight in engines, exhaust systems, and energy applications.

Prototype to production titanium assemblies

Whether you need titanium prototype machining or low-volume titanium production, we run the same robust workflow: DFM review, optimized multi-axis toolpaths, and full inspection. That means you can prove out one-off custom titanium CNC parts and then roll into repeatable batches with minimal change in setup or quality.

End-to-End Titanium 5-Axis CNC Machining Process

Our titanium 5-axis CNC machining services run on a tight, closed-loop process so you get consistent quality from RFQ to delivery.

DFM Review for Titanium Parts

We start with a DFM review of your titanium 3D models and drawings (STEP, IGES, SolidWorks, PDF).

We check:

- Machinability of complex titanium geometries

- Wall thickness, fillets, and tool access for 5-axis milling

- Tolerances, datum structure, and critical features

If we see a way to reduce cost or lead time, we’ll suggest small design tweaks before we cut any titanium.

CAM Programming for 5-Axis Titanium Milling and Turning

Our CAM engineers build optimized toolpaths for:

- Simultaneous 5-axis titanium milling

- Multi-axis turning for tight tolerance titanium parts

- Safe tool engagement to control heat and tool wear

We simulate every program to avoid collisions and overcut on your precision titanium components.

Tooling and Cutting Parameters for Titanium Alloys

Titanium is unforgiving, so we use:

- Dedicated carbide and coated tools for Ti-6Al-4V CNC machining and other grades

- Conservative, proven cutting parameters to protect surface integrity

- Coolant strategies tailored to each titanium alloy

Tool selection and feeds/speeds are tuned separately for prototype and production runs.

Roughing, Semi-Finishing, and Finishing

We split the process to hit both efficiency and accuracy:

- Roughing: high-efficiency toolpaths to remove bulk titanium fast

- Semi-finishing: stabilize geometry and prep for final cuts

- Finishing: light passes to achieve tight tolerances and smooth surfaces

This flow keeps distortion low and surface quality high, even on thin-wall titanium parts.

In-Process Inspection & First Article

During machining we run:

- In-machine probing for key dimensions

- First Article Inspection (FAI) for new titanium 5-axis CNC machining projects

- CMM checks on critical features and tight positional tolerances

Measurement data is used to fine-tune the process before we move to full production.

Final Inspection, Packaging & Shipping

Before parts leave the shop:

- Final dimensional inspection with CMM and gauges

- Visual and cosmetic checks on functional and visible faces

- Clean, protected packaging to avoid dings on titanium surfaces

Our global customers get stable quality and repeatable results backed by a controlled CNC manufacturing process and clear documentation on every titanium batch.

Surface Finishing & Post-Processing for Titanium 5-Axis CNC Parts

As-machined titanium finishes

With our titanium 5-axis CNC machining services, you can go with an as-machined finish when function matters more than looks. We control toolpaths and cutting parameters to keep surfaces consistent, avoid burrs, and hit tight dimensions on precision titanium machining without unnecessary extra steps or cost.

Bead blasting & polishing

For parts that need better cosmetics or smoother handling, we offer:

- Bead blasting – matte, uniform look, great for custom titanium CNC parts, brackets, and housings.

- Mechanical polishing – lower Ra, cleaner reflection for visible high-performance titanium components and consumer products.

Titanium anodizing (color & performance)

We support titanium anodizing for both appearance and function:

- Thin oxide layers for color coding, branding, or quick ID of medical titanium components.

- Surface enhancement for wear resistance and easier cleaning in aerospace titanium machining applications.

Passivation & precision cleaning

For medical, dental, and aerospace titanium parts, we use controlled cleaning and passivation processes to:

- Remove contaminants and machining residues

- Improve corrosion resistance

- Meet typical regulatory and cleanliness expectations for implants and critical flight hardware

If you’re working on regulated medical programs, you can also review our dedicated medical machining capabilities for more context.

Heat treatment & stress relief

Depending on the titanium grade and part geometry, we can add:

- Stress relief after heavy roughing of Ti-6Al-4V and Grade 5 structures

- Targeted heat treatment to stabilize tight tolerance titanium parts and improve long-term dimensional stability under load and temperature.

Marking, engraving & labeling

We handle part identification and traceability directly on the component:

- Laser marking for logos, serials, QR/DataMatrix codes

- Engraved part numbers or orientation marks for assembly

- Permanent tracking for

Quality Control and Certifications for Titanium 5-Axis CNC Machining

When you order titanium 5-axis CNC machining services from us, you’re buying into a controlled, audited process—not guesswork.

Certified Quality Systems

We run titanium CNC machining under a strict quality framework:

- ISO 9001 and AS9100-driven processes for repeatable, precision titanium machining

- Documented work instructions and process controls for every titanium 5-axis job

- Risk-based planning for aerospace, medical, and high-reliability titanium components

If your project needs formal documentation, we can align with your internal quality system and customer-specific standards.

Material Certification & Full Traceability

Every piece of titanium we machine is traceable:

- Mill certs / material certificates for all titanium grades (e.g., Ti-6Al-4V, Grade 5, Grade 23)

- Heat/lot traceability from raw titanium bar/plate/forging to finished part

- Stored records that link titanium stock, programs, tools, and final measurements

This level of traceability is a must for aerospace titanium parts, medical titanium components, and any regulated industry.

FAI, PPAP & Documentation Support

For new and critical titanium parts, we support:

- First Article Inspection (FAI) (AS9102 style on request)

- PPAP levels for automotive or strict production launches

- Full measurement reports, inspection sheets, and capability data where required

You can also attach your inspection requirements directly when you submit a project via our online titanium machining RFQ form.

ITAR & Export-Controlled Titanium Parts

For defense and sensitive aerospace work:

- ITAR / export control–aware workflows for titanium components

- Secure handling of controlled drawings and CAD models

- Restricted data access only to cleared internal staff

We keep your defense and aerospace titanium machining projects properly controlled and off-limits to unauthorized parties.

Measurement & Inspection for Tight Tolerance Titanium Parts

To hold tight tolerance titanium parts (up to ±0.005 mm / ±0.01 mm), we rely on:

- CMM inspection (coordinate measuring machine) for complex 5-axis titanium geometries

- Optical and vision systems for tiny features and micro details

- Height gauges, bore gauges, pin gauges, and calibrated hand tools for production checks

Measurement reports are available with every batch on request, so your team can verify compliance quickly.

Process Controls to Reduce Defects in Titanium Machining

Titanium is unforgiving, so we build quality into the process, not just at final inspection:

- Stable 5-axis machining parameters tuned for titanium alloys

- Controlled coolant, chip evacuation, and toolpath strategies to protect surface integrity

- Tool life management and tool break detection to avoid scrap and hidden damage

- In-process checks on critical dimensions to catch drift before it becomes a batch issue

If you need more detail on how we manage quality for precision titanium machining, our online FAQ and resource section covers the basics and what to expect from our titanium CNC machining service.

Prototyping and Production for Titanium Parts

Rapid titanium prototyping with 5-axis machining

With our titanium 5-axis CNC machining services, we move from CAD to physical parts fast. We use simultaneous 5-axis titanium milling and turning to cut out extra setups, so you get functional titanium prototypes that match final production quality in days, not weeks. This is ideal when you need real-world testing for Ti-6Al-4V CNC machining parts, complex brackets, or custom titanium CNC parts.

Low-volume and bridge production

Once prototypes are locked, we support low-volume and bridge builds for pilots, validation, and early customer shipments. Our process is tuned for:

- 1–50 pcs: engineering validation and test

- 50–300 pcs: bridge to tooling or long-term CNC

- Ongoing low-volume: high-mix, precision titanium machining

Multi-axis titanium machining and standardized setups let us keep quality tight while holding cost under control.

Scaling to medium-volume titanium runs

For medium-volume titanium production, repeatability is everything. We lock in:

- Stable 5-axis toolpaths for each titanium alloy

- Dedicated fixtures and in-process CMM checks

- Controlled parameters for grade 5 titanium machining

This gives you consistent, tight tolerance titanium parts across batches, suitable for aerospace titanium machining and medical titanium machining services.

Lead times: prototype vs production

Typical timing (varies by geometry and spec):

- Prototypes: ~5–12 business days

- Low-volume / bridge: ~2–4 weeks

- Medium-volume: ~4–6 weeks

Tighter tolerances, complex titanium geometries, and special finishes can extend lead time. Clear specs up front help us quote realistic schedules.

Cost drivers across volumes

Main pricing factors for titanium CNC machining service:

- Material: titanium bar/plate cost and buy-to-fly ratio

- Geometry: deep pockets, thin walls, and undercuts increase 5-axis time

- Tolerances & finish: Ra 0.4 μm surfaces and tight tolerance titanium parts (up to ±0.005 mm / ±0.01 mm) need more setups and inspection

- Volume: higher quantities spread programming, fixturing, and setup cost

You can see how titanium compares to other metals on our CNC metal materials page.

Design tips for faster turnaround

To speed up both prototyping and production of titanium alloy CNC services, keep in mind:

- Use standard radii (tools: 2, 3, 6, 8, 10 mm, etc.)

- Avoid ultra-thin unsupported walls where possible

- Relax tolerances to “functional” only, not blanket tight

- Call out critical features clearly in your drawing

- Choose common alloys like Ti-6Al-4V (Grade 5) or Grade 23 when possible

If you need help, we can review your models with DFM feedback and suggest tweaks that cut machining time, cost, and lead time. For a full view of our capabilities, you can also check our main CNC machining services overview.

Cost Factors in Titanium 5-Axis CNC Machining

How titanium cost impacts part pricing

Titanium is expensive per kg, and buy-to-fly ratio matters a lot. If we start from a large billet and remove 80–90% of the material, your part cost climbs fast.

To keep pricing under control, we focus on:

- Choosing stock sizes close to final dimensions

- Nesting multiple parts in one blank where possible

- Matching titanium grade (e.g., Ti-6Al-4V vs CP grades) to real performance needs

Geometry complexity and 5-axis setups

With titanium 5-axis CNC machining services, complexity is a key cost driver:

- Deep pockets, thin walls, undercuts, and organic shapes add programming time

- Multiple re-orientations or special fixtures increase setup cost

- True simultaneous 5-axis toolpaths are more efficient, but require more CAM time

If you can relax features (fewer undercuts, slightly thicker walls), we can often save you 10–30% on complex titanium parts.

Tolerances and surface finish

Tight tolerance titanium parts (up to ±0.005 mm / ±0.01 mm) and fine finishes push cost up because they require:

- Extra finishing passes and smaller stepovers

- Slower feeds and speeds for stability

- More in-process inspection and CMM time

Costs rise sharply when you specify: - Positional tolerances below 0.01 mm

- Surface roughness better than Ra 0.4 μm over large areas

Use tight tolerances only where function truly depends on them.

Tool wear, cycle time, and machine time

Titanium is tough on tools and generates heat. That means:

- More frequent tool changes and premium tooling

- Lower cutting speeds vs aluminum or mild steel

- Longer cycle times per part

We manage this with optimized toolpaths, high-pressure coolant, and smart roughing strategies, but tool and machine time are still major cost components in precision titanium machining.

Design tips to reduce cost

You can cut titanium CNC machining cost without sacrificing performance by:

- Avoiding ultra-deep cavities and extremely thin walls

- Standardizing radii and hole sizes to match common tools

- Relaxing non-critical tolerances and surface finish

- Grouping orders into small batches instead of many tiny runs

If you share 3D models early, we’ll give straightforward DFM feedback to simplify the design before you lock it in.

Budgeting and quoting expectations

For titanium alloy CNC services, pricing is driven by:

- Material grade and raw stock volume

- 5-axis machining time and setups

- Inspection level and documentation requirements (FAI, full reports)

When you request a quote, we’ll break down key cost drivers so you can see where to optimize. For broader program planning or related components (e.g., motorsport or EV parts), you can also check our automotive machining capabilities on our automotive manufacturing services page or review technical guides in our resources section.

How to Prepare a Titanium Machining RFQ

If you want accurate quotes and shorter lead times for titanium 5-axis CNC machining services, a clean RFQ is key. Here’s what I ask every customer to send so we can quote fast and right the first time.

Required Files and Formats

For titanium CNC machining service, please include:

- 3D CAD file:

- Preferred: STEP (.step / .stp)

- Also accepted: IGES (.igs / .iges), SolidWorks (.sldprt)

- 2D drawing (PDF) with:

- Dimensions and tolerances

- Surface finish callouts

- Notes on threads, chamfers, radii, and machining symbols

If you have assemblies, send both the top-level STEP and individual part files.

Key Technical Details to Include

To quote precision titanium machining correctly, include:

- Quantity: prototype, low-volume, or production (e.g. 5 / 50 / 500 pcs)

- Target lead time or required delivery date

- Tolerances: standard vs tight tolerance titanium parts (e.g. ±0.01 mm or ±0.005 mm)

- Surface finish:

- As-machined, Ra requirement (e.g. Ra 0.8 μm / Ra 0.4 μm)

- Any cosmetic faces that matter more than others

- Special features:

- Threads, thin walls, deep pockets, impellers, blisks, organic 5-axis titanium milling areas

- Budget indication (if you have one) for best cost/DFM suggestion

Specifying Titanium Grade and Certifications

Titanium alloy choice drives cost, tool wear, and performance. Please specify:

- Titanium grade (examples):

- Ti-6Al-4V Grade 5 – common for aerospace titanium machining, general high-strength use

- Ti-6Al-4V ELI Grade 23 – medical titanium machining services, implants, biocompatible titanium components

- CP Titanium Grade 2 / 3 / 4 – good corrosion-resistant titanium parts, lower strength, easier to machine

- Certifications required:

- Material certs (EN10204 3.1 / 3.2, mill certs)

- ISO 9001 or AS9100 process requirements

- Biocompatibility / medical grade documentation if for implants

- Any LOT traceability or heat number tracking

If you’re unsure which titanium alloy CNC services to go with, tell us the application (aerospace, automotive, implant, marine, energy) and we’ll recommend a grade.

Flagging Critical Dimensions and Inspection Requirements

For tight tolerance titanium parts and complex titanium geometries, call out what really matters:

- On the PDF drawing, mark critical dimensions with:

- A flag, triangle, or “CRIT” note

- GD&T symbols for flatness, roundness, true position where needed

- Define inspection level:

- Standard in-process checks

- 100% inspection of key features

- CMM inspection report or full measurement report

- State if you need:

- First Article Inspection (FAI)

- PPAP or specific aerospace / medical documentation

This helps us focus our CMM and optical inspection effort where it counts, and price it correctly.

NDA and Confidentiality

We work with a lot of proprietary titanium designs in aerospace, defense, medical, and motorsport. If you need formal cover:

- Send your NDA or ask for ours before sharing files

- Tell us if there are any ITAR / export control restrictions

- Mark files and drawings as CONFIDENTIAL if required

All titanium CNC milling and turning data is stored securely, and we only share it internally on a need-to-know basis to run your job.

What to Expect After Submitting a Titanium RFQ

Once you send your titanium 5-axis CNC machining RFQ:

- RFQ review & DFM check

- We review for manufacturability, risk points (thin walls, deep pockets, 5-axis undercuts), and cost drivers.

- Clarification (if needed)

- We may come back with questions on tolerances, titanium grade, finishes, or inspection depth.

- Formal quote

- You’ll get:

- Unit price by quantity

- Lead time (prototype vs production)

- Included inspections and documentation

- Any suggested design tweaks to reduce cost or risk

- You’ll get:

- Order confirmation & schedule

- Once approved, we lock the titanium machining slot and share a target ship date.

The more complete your titanium machining RFQ, the faster we can commit on price, lead time, and process for your custom titanium CNC parts.

Common Challenges in Titanium 5-Axis CNC Machining Services

Titanium 5-axis CNC machining services are powerful, but titanium is not a friendly material. If you don’t know what you’re doing, costs, scrap rate, and lead times go up fast. Here’s how we handle the tough parts.

Why Titanium Is Difficult to Machine

Titanium heats up and punishes tools if you don’t control the cut:

- Low thermal conductivity: Heat stays at the cutting edge, not in the chips.

- High strength and hardness: More cutting forces, more wear.

- Galling and built-up edge: Titanium can weld to the tool if speeds/feeds and coolant are wrong.

We run optimized 5-axis titanium milling parameters, rigid setups, and high-pressure coolant to pull heat out and keep the cut clean.

Distortion and Residual Stress in Titanium Parts

Thin or long titanium parts can move as you remove material:

- Internal stress in the titanium billet

- Heavy material removal from one side

- Poor clamping or uneven support

To control distortion, we use:

- Stress-relieved titanium stock when needed

- Balanced machining (rough both sides)

- Multiple semi-finishing passes to “relax” the part before final size

Tool Life and Surface Integrity

With titanium CNC machining, tool life and surface quality are directly linked:

- If tools wear early, you get burned surfaces, micro-cracks, and poor fatigue life.

- Wrong tooling = chatter marks, burrs, and inconsistent dimensions.

We extend tool life and protect surface integrity by:

- Using premium carbide and coated tools built for titanium

- Tight control on tool load, step-over, and chip thickness

- Scheduled tool changes for critical features (not “run until broken”)

Fixturing and Workholding for Thin-Wall Titanium

Thin-wall titanium and complex 5-axis geometries are hard to hold:

- Parts vibrate, flex, and “breathe” under cutting forces.

- Standard vises often don’t work for these shapes.

We use:

- Custom soft jaws and 5-axis fixtures

- Vacuum and modular fixturing for large, thin parts

- Support ribs and tabs in the design (or added for machining then removed)

Avoiding Chatter and Dimensional Drift

Chatter kills accuracy and finish, especially in multi-axis titanium machining:

- Poor tool reach-to-diameter ratios

- Unstable workholding

- Aggressive cutting data

Our strategies:

- Short, rigid tools wherever possible

- Optimized 5-axis toolpaths to keep a constant tool engagement

- Dynamic milling and trochoidal toolpaths to reduce cutting forces

- Real-time adjustments if we see vibration in process

How Experience and Process Control Reduce Titanium Risk

Titanium 5-axis CNC machining services are all about process discipline:

- Proven DFM for tight tolerance titanium parts (up to ±0.005 mm / ±0.01 mm)

- Locked-in process sheets for repeat titanium CNC jobs

- In-process inspection (CMM, probes, gauges) to catch drift early

- Continuous monitoring of tool wear, temperature, and machine stability

Because we run precision titanium machining every day (Ti-6Al-4V, Grade 5, Grade 23, and more), we know where titanium projects typically fail—and we build our process to avoid those failures before they hit your schedule or budget.

FAQ on Titanium 5-Axis CNC Machining Services

What’s the minimum order quantity for titanium machined parts?

I support everything from single-piece titanium prototypes to repeat production runs.

- MOQ: 1 piece for development and validation

- For production, I’ll recommend economic batch sizes based on cycle time and setup cost

Typical lead times for titanium prototypes and production

Lead time depends on complexity, titanium grade, and inspection level:

- Prototypes: usually 7–15 working days

- Low-volume / bridge runs: around 2–4 weeks

- Ongoing production: scheduled based on your forecast and release plan

Maximum part size and complexity I can handle

With titanium 5-axis CNC machining services, I handle complex titanium geometries in one setup. Typical capability:

- Max envelope: up to roughly 800 × 500 × 500 mm (varies by machine)

- Ideal for impellers, blisks, titanium brackets, frames, and organic shapes

Send your model and I’ll confirm feasibility and best machining strategy.

Supported CAD formats and drawing standards

For precision titanium machining and DFM, I work with:

- 3D: STEP, IGES, Parasolid, SolidWorks

- 2D: PDF, DXF, DWG for critical dimensions and GD&T

- Drawing standards: ISO, ASME – just specify your default in the RFQ

Shipping, packaging, and global delivery

I ship custom titanium CNC parts worldwide with:

- Individual protection (foam, tray, or bubble wrap) to avoid denting titanium surfaces

- Labeled packaging with part number, revision, and batch info

- Express or economy options based on your program timing

You can see how I support different sectors globally on my industries and applications page.

Intellectual property and file security

Your IP is locked down:

- NDA-friendly – I work under your NDA or provide mine

- Secure file handling with controlled access and retention

- Drawings, 3D models, and specs are only shared internally on a need-to-know basis

- I don’t reuse, resell, or disclose your titanium designs, tooling paths, or fixtures to other customers.

Reviews

There are no reviews yet.