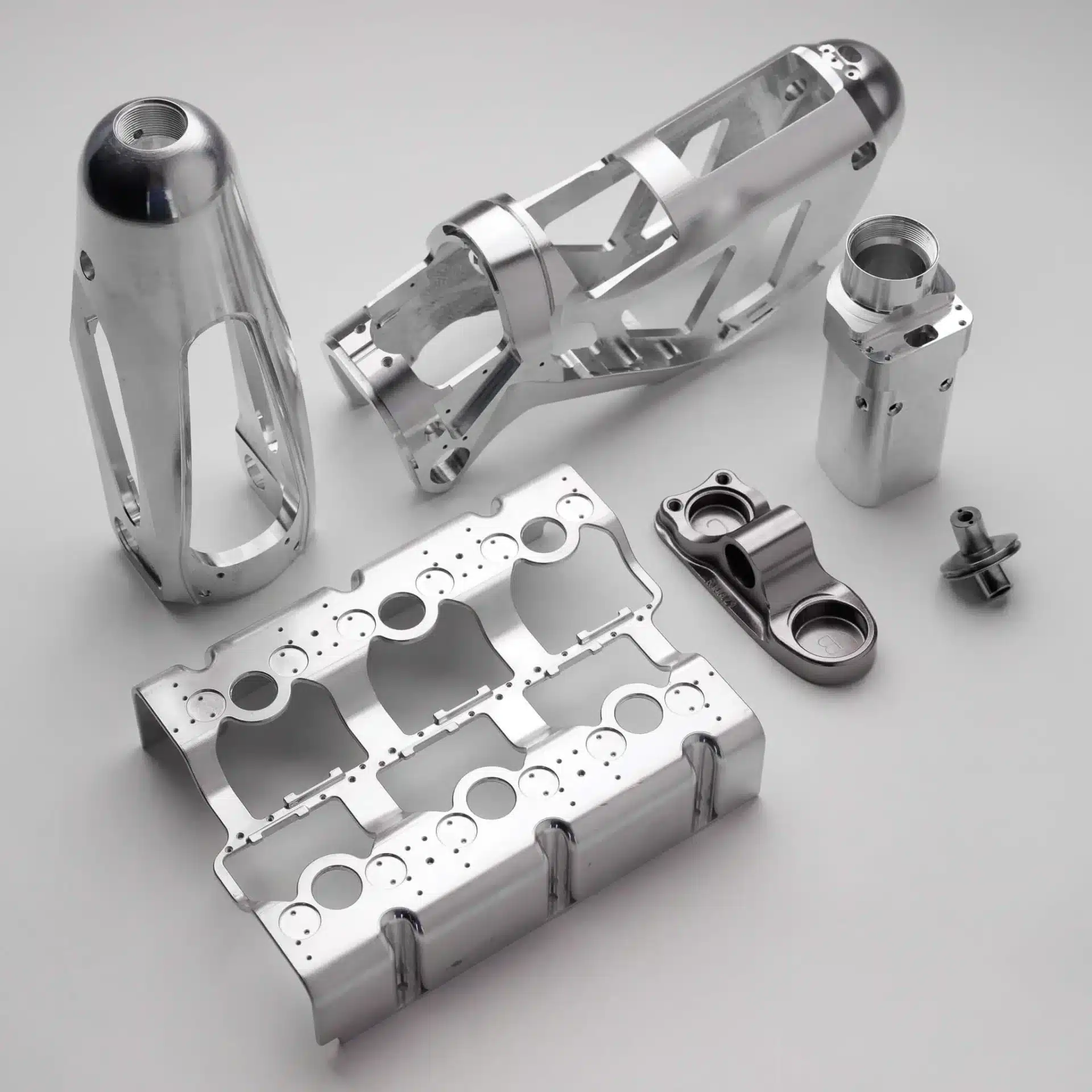

Our Secondary Finishing Capabilities

Getting a part machined is only half the battle; the finish defines its performance and market readiness. We provide a comprehensive suite of Secondary Finishing Services designed to take your components from raw manufacturing to final application seamlessly. With access to over 30 finishing options for CNC and 25+ for Sheet Metal, we ensure your parts meet strict cosmetic and functional standards without the logistical headache of managing multiple vendors.

Surface Smoothing & Deburring

We eliminate machining marks and sharp edges to achieve the perfect texture. Our Bead Blasting services offer versatile grit options ranging from 30 to 220 grit, allowing for everything from heavy texturing to soft, smooth finishes. For higher aesthetic requirements, we offer polishing and brushing to refine surface roughness and improve visual appeal.

- Bead Blasting: 30–220 grit for custom textures.

- Smoothing: Removal of burrs and machining lines.

- Aesthetics: Polishing and brushing for high-grade visual finishes.

Protective Coatings & Plating

Enhance durability and corrosion resistance with our industrial-grade coatings. We specialize in Anodising (Type II, Hard, and Color Matching) to protect aluminum parts while adding color. For superior wear resistance and aesthetic variety, we offer Powder Coating and painting. Our plating capabilities include Galvanic Zinc, Nickel, and Chrome, ensuring your parts survive harsh environments.

Heat Treatments & Material Compatibility

We don’t just change how a part looks; we optimize how it performs. Our heat treatment services include Quenching, Tempering, and Normalizing to alter mechanical properties for stress relief and hardening. These finishes are compatible across our massive library of 160+ materials, including Aluminum, Stainless Steel, and various engineering plastics, ensuring your post-machining finishing needs are met regardless of the substrate.

Detailed Process Descriptions

We bridge the gap between raw manufacturing and market-ready components through a comprehensive suite of secondary finishing services. Our integrated manufacturing process ensures that every part meets strict aesthetic and functional requirements before delivery.

Anodizing Services

We provide high-quality Anodising (Type II) and Hard Anodising (Type III) to increase corrosion resistance and surface hardness. This electrochemical process allows for extensive color matching and is essential for aluminum parts requiring a durable, non-conductive finish. We also offer specialized masking techniques to maintain conductivity in specific areas if needed.

Bead Blasting Techniques

Our bead blasting capabilities allow for precise surface texturing, effectively removing machining marks and burrs. We utilize a range of media to achieve the desired finish, from heavy textures to smooth, satin-like appearances.

- Grit Range: We operate with grit levels ranging from 30 (Heavy) to 220 (Soft).

- Application: Ideal for preparing surfaces for painting or achieving a uniform matte cosmetic finish.

Powder Coating & Painting

For superior durability and aesthetic variety, we offer powder coating and wet painting. These finishes provide a thick, protective layer that resists chipping, scratching, and fading, making them suitable for industrial and consumer-facing products.

Chemical Treatments & Plating

We utilize advanced chemical processes to enhance the properties of metal components, particularly for stainless steel and carbon steel parts. Our capabilities include Galvanic Zinc, Nickel, and Chrome plating, which offer robust protection against oxidation and wear.

Comparison of Common Finishes:

| Finish Type | Key Feature | Typical Application |

|---|---|---|

| Anodising (Type II) | Corrosion resistance, color options | Consumer electronics, brackets |

| Hard Coat Anodising | High wear resistance, thicker coat | Industrial gears, sliding parts |

| Bead Blasting | Uniform matte texture (30-220 Grit) | Visual prototypes, pre-coating prep |

| Powder Coating | Impact resistance, aesthetic variety | Enclosures, automotive parts |

| Nickel/Chrome Plating | Hardness, mirror-like finish | Decorative trim, wear components |

Quality Standards & Certifications

ZSCNC Quality Management System and ISO 9001 Compliance

We operate under a strict Quality Management System (QMS) aligned with ISO 9001:2015 standards. This ensures that every component leaving our facility meets the highest benchmarks for consistency and performance. Our integrated approach means that secondary finishing services are monitored with the same rigor as our primary machining processes. By adhering to these global standards, we minimize risk and guarantee that your parts are production-ready upon delivery. For a deeper look at our protocols, you can review our comprehensive quality control system which governs every stage of production.

Industry Certifications: RoHS, REACH, and ITAR Standards

Compliance is non-negotiable in modern manufacturing. We ensure that our finishing processes, including anodizing and plating, adhere to RoHS and REACH regulations, restricting hazardous substances for environmental and safety compliance. For sensitive defense and aerospace projects, we maintain strict adherence to ITAR standards, ensuring that data security and part handling meet the rigorous demands of controlled goods.

Inspection Protocols: Visual Checks, Dimensional Analysis, and Adhesion Testing

To guarantee the integrity of our secondary finishing services, we implement a multi-stage inspection protocol. This includes:

- Visual Checks: Technicians inspect for cosmetic defects, color consistency, and surface uniformity.

- Dimensional Analysis: We verify that coating thicknesses do not interfere with critical tolerances, ensuring parts fit their intended assemblies.

- Adhesion Testing: Functional tests are performed to ensure coatings and platings bond securely to the substrate and will not peel under stress.

Salt Spray Testing and Durability Verification

For components exposed to harsh environments, we validate corrosion resistance through rigorous methods like salt spray testing. This verification process simulates years of environmental exposure to ensure that protective coatings, such as chromate conversion or hard coat anodizing, perform as expected. This data-driven approach confirms that the finish provides the necessary longevity and protection for your specific application.

Commitment to Full Traceability and Quality Documentation

We provide complete transparency throughout the manufacturing cycle. From the raw material batch to the final surface treatment, every step is documented. We supply full quality reports, including Certificates of Conformity (CoC) and material certifications, ensuring you have a complete audit trail for your records. This level of traceability is essential for industries requiring strict validation, such as medical and aerospace sectors.

Benefits of Choosing ZSCNC for Secondary Finishing

Managing multiple vendors for machining and finishing is a logistical headache that often leads to delays and finger-pointing. At ZSCNC, we streamline the entire manufacturing process. By integrating secondary finishing services directly with our manufacturing capabilities, we provide a seamless “one-stop” solution for global customers.

Single-Source Responsibility

We take full ownership of your parts from the initial cut to the final coat. When we handle both the manufacturing and the post-machining finishing, we eliminate the risk of disputes between the machine shop and the finishing house regarding quality issues. This integration is particularly critical for complex 5-axis CNC machining projects where maintaining tight tolerances through the finishing process is non-negotiable.

Reducing Lead Times and Logistics Costs

Shipping parts back and forth between a machinist and a plating vendor adds days or even weeks to your timeline. Our in-house capabilities and established local partnerships for specialized surface treatment for CNC parts significantly reduce this downtime.

Why Integrated Finishing Saves Time & Money:

- Zero Transit Time: Eliminates shipping days between production stages.

- Lower Shipping Costs: You only pay for shipping the final, finished product.

- Faster Corrections: If a finish adjustment is needed, we handle it immediately without external logistics.

Consistent Quality Control

Quality isn’t just about the final look; it’s about how the finish interacts with the part’s geometry. Our quality control team inspects parts before and after secondary operations machining. We understand how anodizing services or powder coating affect dimensional tolerances, ensuring that the final component fits perfectly in your assembly.

Expert Engineering Support for Finish Selection

Choosing the right finish can be difficult. Our engineers assist you in selecting the optimal treatment based on material properties and end-use environment. Whether you need biocompatible finishes for medical device prototypes or corrosion-resistant coatings for marine applications, we guide you toward the best solution. We advise on:

- Material Compatibility: Ensuring the alloy matches the chemical treatment.

- Tolerance Stacking: Accounting for coating thickness in the design phase.

- Aesthetic Requirements: achieving specific Ra roughness and texture goals.

Competitive Pricing Strategies

Bundling your machining and finishing orders allows us to offer more competitive pricing. We reduce administrative overhead and setup costs, passing those savings directly to you.

| Feature | Traditional Multi-Vendor Sourcing | ZSCNC Integrated Service |

|---|---|---|

| Accountability | Split responsibility (High Risk) | Single point of contact (Low Risk) |

| Logistics | Multiple shipping legs | Direct to customer |

| Lead Time | Extended by transit/queues | Streamlined and fast |

| Cost | Compounded shipping & markup | Optimized bundled pricing |

Industries We Serve

Our secondary finishing services are engineered to meet the strict requirements of highly regulated sectors. By leveraging a global network of vetted manufacturing partners, including those with AS9100 accreditation, we ensure every surface treatment enhances both the function and longevity of your components.

Aerospace & Defense

Precision and reliability are non-negotiable in aerospace applications. We collaborate with specialized partners to deliver Mil-Spec coatings and surface treatments that withstand extreme environmental stress.

- Key Finishes: Hard coat anodizing (Type III), chemical conversion coating, and passivation.

- Benefit: Enhanced corrosion resistance and surface hardness for flight-critical hardware.

Medical Devices

Quality assurance is paramount in the medical field. Holding ISO 13485 accreditation, we guarantee that post-machining finishing meets rigorous hygiene and safety standards. Our medical device CNC machining services are complemented by biocompatible finishes suitable for surgical instruments and implants.

- Key Finishes: Electropolishing, passivation, and bead blasting for uniform matte textures.

- Benefit: Removes surface contaminants and improves sterilization capabilities.

Industrial Equipment & Robotics

Automation hardware requires finishes that resist wear and reduce friction during repetitive operation. We apply durable protective coatings to robotics and automation components to extend their service life and maintain precision tolerances.

- Key Finishes: Black oxide, nickel plating, and powder coating.

- Benefit: Superior abrasion resistance and protection against industrial chemicals.

Automotive & Transportation

From under-the-hood performance to interior aesthetics, our finishing capabilities cover the full spectrum of automotive needs. We provide solutions that balance cosmetic appeal with rugged durability against road salts and weathering.

- Key Finishes: Anodizing (Type II), painting, and chromate conversion.

- Benefit: High-impact visual appeal combined with long-term corrosion protection.

Technical Specifications & Tolerances

We adhere to strict ISO 9001:2015 standards to ensure that secondary finishing services enhance your parts without compromising their mechanical integrity. Our global network achieves precision tolerances as tight as +/- 0.001mm for CNC machined components, though post-processing requires careful dimensional planning.

Achievable Surface Roughness (Ra Values)

Surface roughness is critical for both functionality and aesthetics. We offer a range of finishes from standard “as machined” to high-grade polishing. Understanding how these finishes interact with aluminum CNC machining tolerances is vital for ensuring proper assembly fit.

| Finish Type | Typical Ra Value (µm) | Description |

|---|---|---|

| As Machined | 3.2 µm | Standard finish with visible tool marks. |

| Smooth Machined | 1.6 µm | Reduced tool marks for better aesthetics. |

| Polished | 0.8 µm – 0.4 µm | High-grade finish, ideal for sealing surfaces. |

| Bead Blast | Varies (Matte) | Uniform texture determined by grit selection. |

Bead Blasting Grit & Texture Options

For bead blasting, we utilize a specific range of grit levels to control the texture and visual appearance of the part. This process removes machining marks and creates a uniform matte surface.

- Heavy Texture: 30 – 80 Grit

- Medium Texture: 100 – 150 Grit

- Soft/Fine Texture: 180 – 220 Grit

Coating Thickness & Dimensional Uniformity

Applying protective coatings like powder coating or anodising will impact the final dimensions of your component.

- Anodising (Type II & III): Converts the surface aluminum oxide. While Type II is mainly cosmetic, Hard Anodising (Type III) adds a thicker, wear-resistant layer.

- Powder Coating: Adds a distinct layer of material (typically 30-80 microns) on top of the surface.

- Dimensional Reports: For critical features, we recommend requesting formal inspection reports, which may extend lead times by 1-3 days but guarantee compliance with your specifications.

Advanced Masking & Color Matching

We support selective surface finishing through advanced masking techniques. This allows us to apply coatings to specific areas while keeping critical features—such as grounding points, threads, or bearing bores—free of coating to maintain tight tolerances.

- Color Matching: We offer standard anodising colors (Black, Clear, Blue, Red, Gold) and can accommodate custom requests.

- Batch Consistency: Our “best of 3” benchmarking and centralized quality control ensure color and texture consistency across production batches, whether for a single prototype or 50,000 units.

Ordering Process and Workflow

Step-by-Step Guide: Upload CAD, Select Finish, and Receive Quote

Getting a quote for secondary finishing services should be as fast as the manufacturing itself. We have streamlined the process to remove friction for engineers and procurement teams. Simply upload your 3D CAD files to our online engine to get started. From the dashboard, you can configure your requirements, selecting from over 30 different finish options—from bead blasting to hard coat anodizing.

For most standard projects, our system generates an instant quote. If your project involves complex post-machining finishing requirements or specific cosmetic standards, our engineering team reviews the data to provide a verified quote within 24 hours. This ensures you get the best price benchmarking without sacrificing precision on your custom aluminum CNC machined parts.

Understanding Lead Times for Common and Custom Finishing Combinations

We know that speed is critical. Our standard turnaround for parts can be as fast as 3 to 5 days, depending on geometry and quantity. Adding surface treatment for CNC parts naturally impacts the timeline, but we work to minimize delays.

- Standard Finishes: Basic processes like bead blasting (grit 30-220) or standard anodizing typically add minimal time to the production schedule.

- Complex Finishes: Custom color matching, masking for selective plating, or specialized part passivation may extend lead times slightly to allow for rigorous quality checks.

- Inspection Time: If your parts require formal dimensional reports or specific surface roughness inspections (e.g., verifying Ra values), we factor this into the delivery date upfront.

From Approval to Manufacture: Streamlining Your Production Run

Once you approve the quote and review our Design for Manufacturing (DFM) feedback, we handle the entire logistics chain. You do not need to manage separate suppliers for machining and secondary operations machining. We integrate the workflow, moving parts seamlessly from the CNC machine or injection mould directly to the finishing stage.

Our process includes a robust quality assurance protocol. We perform physical QC inspections to verify that coatings, textures, and tolerances meet ISO 9001:2015 standards before the parts leave the factory. This “one-stop-shop” approach ensures consistent quality and reduces the administrative burden on your team.

Frequently Asked Questions (FAQ)

What are the minimum order quantities (MOQ) for secondary finishing?

We operate with no Minimum Order Quantities (MOQs). Whether you require a single prototype with a specialized surface treatment or a production run of 50,000+ units, our global partner network scales to meet your needs. This flexibility allows you to validate designs with production-grade finishes before committing to mass manufacturing.

Can you match existing finishes or custom colors?

Yes, we offer extensive custom color matching capabilities. For processes like anodizing and powder coating, we can match specific RAL codes or standard industry colors to ensure brand consistency. Our network supports over 30 secondary finishes, allowing for precise aesthetic alignment with your existing product lines.

What file formats do you accept for finishing quotes?

To generate an accurate quote through our platform, we recommend uploading 3D CAD files in STEP (.stp) or IGES (.igs) formats. These formats provide the geometric data necessary to calculate surface area for coatings and treatments. Proper file preparation helps avoid common top mistakes engineers make when ordering custom CNC parts, ensuring your finishing requirements are interpreted correctly from the start.

What is the difference between cosmetic and functional finishing?

Cosmetic finishing focuses on the visual appeal and tactile feel of the part, such as bead blasting for a matte look or polishing for a mirror-like shine. Functional finishing prioritizes performance, such as hard coat anodizing for wear resistance or chromate conversion for corrosion protection. Many of our services, like 5-axis CNC machining services for complex aluminum parts, utilize finishes that offer both aesthetic and functional benefits.

How do secondary finishing services impact part tolerances?

Secondary finishes add or remove material, which changes the final dimensions of a part. For example, powder coating adds a measurable layer of thickness, while electropolishing removes a microscopic layer. We recommend accounting for these changes during the design phase. Our engineers provide Design for Manufacturing (DFM) feedback to ensure your critical tolerances—as tight as +/- 0.001mm for machining—are maintained after the finishing process.

Reviews

There are no reviews yet.