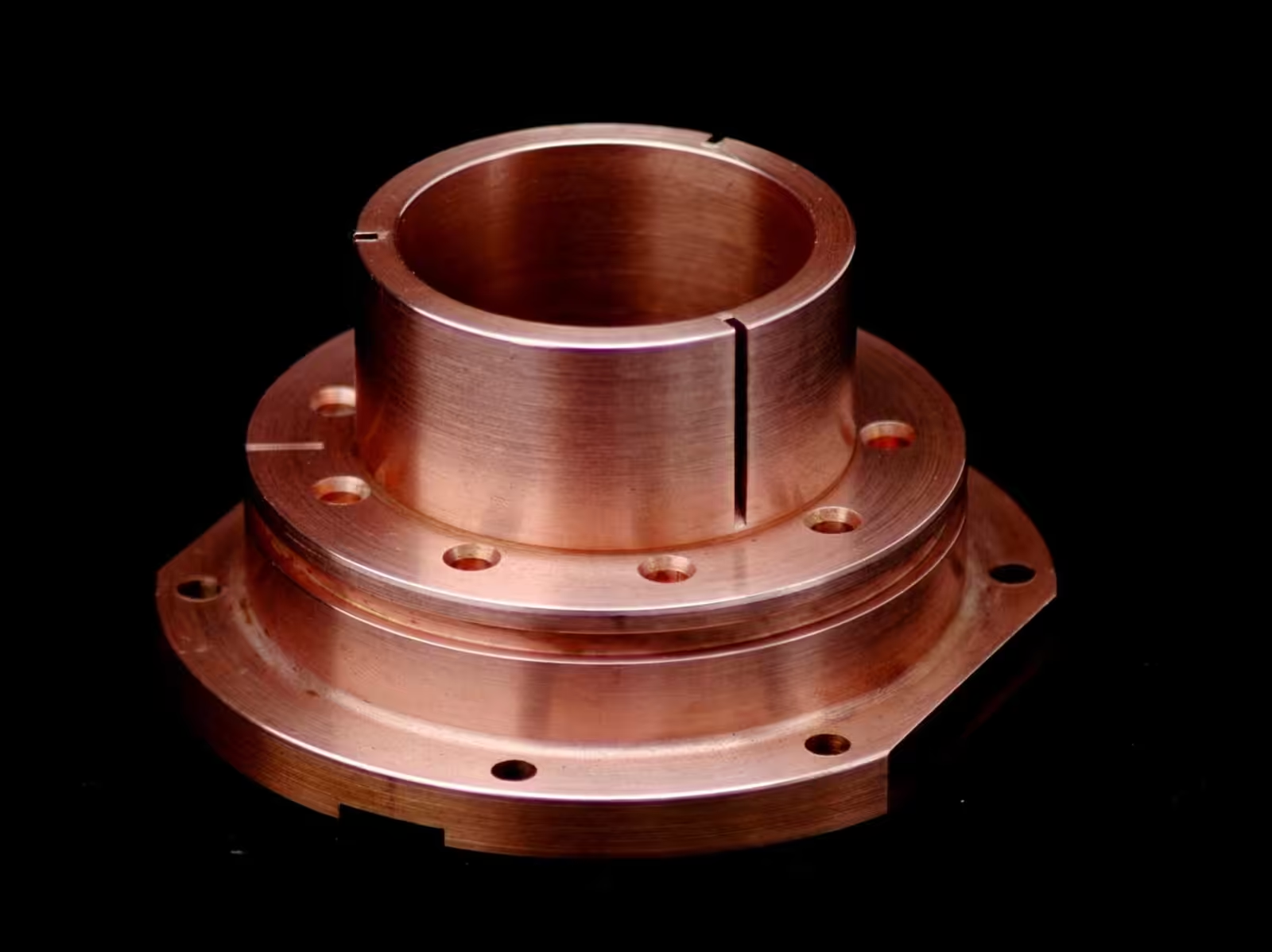

Precision CNC Machining for High-Conductivity Parts

Machining soft, high-conductivity metals presents unique manufacturing challenges. Pure copper and specific brass alloys are notoriously “gummy,” often leading to material smearing, burrs, or deformation if not handled with precise tool geometries and cutting speeds. We specialize in Custom CNC machining of brass, copper and conductive components, ensuring that the electrical and thermal properties of your parts are maintained without compromising dimensional accuracy.

Our facility is optimized for High-Conductivity Alloy Fabrication, utilizing advanced 3, 4, and 5-axis CNC equipment to produce complex geometries for electrical applications. Whether you need intricate battery terminals or heavy-duty busbars, we deliver Precision Copper Milling Services that meet strict engineering standards.

Engineering-Grade Manufacturing Capabilities

We bridge the gap between rapid prototyping and mass production with a factory-direct model that eliminates middleman markups. Our process is ISO 9001:2015 certified, guaranteeing consistency across every batch.

- Handling “Gummy” Metals: We utilize specialized cutting strategies and sharp tooling to machine pure copper (C101/C110) without inducing stress or deformation.

- Micron-Level Precision: Our equipment achieves tolerances as tight as ±0.005mm, essential for high-performance connectors and pins.

- Scalable Production: From a single prototype delivered in 3–7 days to high-volume production runs with lead times of 2–4 weeks.

- Verified Quality: Every order includes full dimensional inspection reports and material certifications to validate conductivity and composition.

Copper and Brass Alloys We Machine

Selecting the right material grade is critical when balancing electrical conductivity with mechanical strength. We stock and machine a wide variety of non-ferrous alloys to meet specific performance requirements for electronic and industrial applications.

High-Conductivity Copper Grades

Our custom copper machining services cover everything from pure OFC to tough, specialized alloys designed for demanding environments.

- C101/C110 Oxygen-Free Electronic Copper (OFC): With 99.99% purity, this is the standard for Oxygen-Free Copper (OFC) Components like high-amp busbars and induction coils where maximum conductivity is non-negotiable.

- C145 Tellurium Copper: Ideal for Tellurium Copper Machining, this alloy offers a perfect balance of high conductivity (90% IACS) and excellent machinability, making it perfect for connector pins and electrical switches.

- C172 Beryllium Copper: Known for its high strength and hardness, we machine this for Beryllium Copper CNC Parts such as springs, clips, and contacts that require fatigue resistance.

Versatile Brass Alloys

For components requiring excellent machinability and corrosion resistance, our brass CNC turning capabilities utilize grades optimized for speed and precision.

- C360 Free-Cutting Brass: The industry standard for C360 Free-Machining Brass Turning. Its lead content allows for high-speed machining with minimal tool wear, ideal for high-volume fittings, fasteners, and sensor housings.

- C260 Cartridge Brass: Offers higher ductility and strength, often used in ammunition casings and deep-drawn parts.

- C464 Naval Brass: Engineered for marine environments, providing superior resistance to saltwater corrosion for specialized hardware.

CNC Milling and Turning Capabilities

To deliver top-tier custom CNC machining of brass, copper and conductive components, we rely on a diverse fleet of machines tailored for soft, gummy metals. Machining high-purity copper isn’t the same as cutting steel; it requires specific strategies to avoid deformation and ensure surface integrity.

Advanced 5-Axis Milling for Complex Geometries

For intricate parts like conductive thermal heatsinks with high fin densities, standard 3-axis milling often falls short. We utilize 5-Axis CNC machining centers to access the workpiece from multiple angles in a single setup. This approach significantly reduces fixture handling errors and allows us to machine complex contours without bending delicate features. Our 5-axis CNC machining services ensure that even the most complicated copper designs meet strict dimensional requirements.

High-Volume CNC Swiss Screw Machining

When production scales up for connector pins, sockets, and terminals, efficiency is key. Our CNC Swiss screw machining capabilities are optimized for producing small, long, and slender parts with high precision.

- Reduced Deflection: The guide bushing supports the material right next to the cutting tool, preventing the “whip” common in standard turning.

- Speed: Ideal for runs ranging from 1,000 to 100,000+ pieces.

- Consistency: Maintains tight tolerances (±0.005mm) on C145 Tellurium Copper and C360 Brass.

Live Tooling and Anti-Smearing Strategies

We integrate live tooling into our precision CNC turning capabilities to perform milling, drilling, and tapping operations without moving the part to a different machine. This “Done-in-One” strategy is crucial for maintaining perfect concentricity between the turned diameter and secondary features like cross-holes.

Furthermore, pure copper loves to stick to cutting tools. To combat this, we use:

- Polished Flute End Mills: Reduces friction and prevents chip welding.

- Sharp Cutting Geometries: Shears the metal cleanly rather than pushing it, preventing material smearing.

- High-Pressure Coolant: Evacuates chips instantly to prevent re-cutting and surface damage.

Surface Finishes and Plating Services

Raw copper and brass offer excellent conductivity, but they are prone to oxidation which increases contact resistance over time. To ensure your custom CNC machining of brass, copper and conductive components performs reliably in the field, we provide a full range of surface treatments tailored for electrical applications. Our finishing process is designed to maintain tight tolerances while enhancing the electrical and physical properties of the metal.

We offer specific treatments to match your connectivity and environmental requirements:

- Silver and Gold Plating Services: Essential for high-frequency applications and critical contacts. Gold offers superior corrosion resistance, while silver provides the highest electrical conductivity of any metal.

- Tin Plating: A cost-effective solution that offers excellent solderability and corrosion protection, making it ideal for large busbars and commercial terminals.

- Nickel Plating: Often used as a diffusion barrier between copper and gold, or as a durable outer finish for wear resistance on connector housings.

- Mechanical Finishing: We achieve precise surface textures, from uniform bead blasting to optical polishing. Understanding the influence of surface roughness (Ra) on part performance is critical for mating surfaces; we can hold finishes as smooth as Ra 0.4 or better for optimal contact.

Industries Relying on High-Conductivity CNC Machined Parts

Our Custom CNC machining of brass, copper and conductive components serves sectors where electrical performance and thermal management are critical. We understand that in high-stakes industries, a single failed connector or poor surface finish can compromise an entire system. We deliver factory-direct precision to meet the rigorous demands of the global market.

Electric Vehicles (EV) and Energy Storage

The shift toward electrification requires robust power distribution components. We specialize in Custom Busbar Manufacturing and battery interconnects using C101/C110 Oxygen-Free Copper. Our parts are designed to handle high currents with minimal resistance, essential for EV battery packs and charging stations. We support the evolving needs of the energy sector by delivering components that ensure safety and efficiency in high-voltage applications.

Telecommunications and RF Infrastructure

Signal integrity is paramount in telecom. We machine complex RF Connector Housings and waveguides that require tight tolerances to prevent signal loss.

- EMI/RFI Shielding Components: We fabricate enclosures from brass and copper to protect sensitive electronics from interference.

- 5G Components: Our 5-axis milling capabilities allow us to produce intricate geometries for next-generation network hardware.

Electronics and Semiconductors

We supply the electronics industry with precision Electrical Contact Machining and Conductive Thermal Heatsinks. Whether for semiconductor testing equipment or high-power consumer electronics, our parts effectively manage heat dissipation while maintaining reliable electrical connectivity. We handle delicate pins and sockets using Swiss screw machining for high-volume consistency.

Aerospace Avionics

Aerospace applications demand lightweight assemblies that do not sacrifice conductivity. We machine avionics components that withstand extreme vibration and temperature fluctuations. By maintaining strict quality control, we ensure every pin and terminal meets the safety standards required for flight-critical systems.

Technical Specifications and Tolerances

At ZS, we bridge the gap between design concepts and physical reality with strict adherence to engineering standards. Whether you require Precision Copper Milling Services for a complex prototype or high-volume CNC Swiss Screw Machining, our facility is calibrated for consistency. We utilize advanced CMM inspection, digital micrometers, and projectors to verify that every dimension matches your print.

To ensure your conductive components fit perfectly within your assemblies, reviewing our standard tolerances for 5-axis parts can help align your design specifications with our manufacturing capabilities. We handle everything from micro-sized pins to large heat sinks.

Manufacturing Capabilities & Standards

| Specification | Details |

|---|---|

| Machining Processes | 3, 4, & 5-Axis Milling, CNC Turning, Swiss Machining |

| Standard Tolerance | ±0.05mm (ISO 2768-m) |

| Precision Tolerance | ±0.005mm ~ ±0.01mm (Upon request for critical features) |

| Surface Roughness | Ra 3.2 (As Machined) to Ra 0.4 (Polished/Ground) |

| Max Milling Size | Up to 1000mm x 600mm x 500mm |

| Max Turning Dia. | Up to 300mm |

| MOQ Flexibility | 1 Piece to 10,000+ Pieces (No Minimum Order Quantity) |

Key Production Features:

- Scalability: We support your project lifecycle from the very first prototype unit to mass production runs without forcing high initial commitments.

- Surface Quality: For electrical applications, we ensure surfaces are free of burrs and scratches that could impede conductivity or signal transmission.

- Material Verification: All High-Conductivity Alloy Fabrication projects come with material certification to prove alloy purity (e.g., C101 vs C110).

The ZSCNC Factory-Direct Advantage

Sourcing high-precision conductive components shouldn’t involve hidden fees or complex communication layers. As a dedicated manufacturer, we eliminate middleman markups, offering you transparent, factory-direct pricing for all custom CNC machining projects. Whether you need a single prototype or mass production of copper connectors, you deal directly with the experts making your parts.

We back our manufacturing with rigorous validation standards. Our ISO 9001:2015 certified facility utilizes advanced CMM inspection and digital projectors to ensure every dimension meets your specifications. We provide full material certifications and dimensional inspection reports with every shipment, ensuring you have complete traceability. You can rely on our strict quality control standards to maintain tolerances as tight as ±0.005mm on critical electrical contacts.

Why partner with ZSCNC?

- Cost Efficiency: No broker fees means better margins for your business.

- Free DFM Reviews: Our engineers analyze your CAD files to suggest design improvements that reduce machining time and material waste.

- Global Logistics: We handle international shipping with ease, ensuring your parts arrive safely and on schedule.

Frequently Asked Questions

How do you prevent copper parts from deforming during machining?

Machining soft, “gummy” metals like Oxygen-Free Copper (OFC) or pure C110 requires a specialized approach to maintain dimensional accuracy. Because copper heats up and expands quickly, we utilize specialized tooling techniques and sharp carbide cutters with high rake angles to reduce cutting pressure.

To prevent warping or crushing, we avoid standard high-force clamping. Instead, we use:

- Vacuum fixtures for flat plates and heat sinks.

- Custom soft jaws that match the part profile.

- Step-down machining to release internal material stress gradually.

This ensures that even delicate Precision Copper Milling Services yield components that are flat, true, and within our tight ±0.005mm tolerance range.

Can you source specific rare copper alloys?

Yes. While we stock standard materials like C360 Brass and C110 Copper for rapid turnaround, our supply chain allows us to source specialized alloys for high-performance applications. We regularly handle:

- C145 Tellurium Copper for high-speed machining of connector pins.

- C172 Beryllium Copper for high-strength, non-sparking springs and contacts.

- C101 Oxygen-Free Electronic Copper for critical vacuum and audio applications.

All materials come with full traceability and Material Certifications upon request, ensuring your Custom CNC machining of brass, copper and conductive components meets strict industry standards.

Do you offer assembly services for electrical components?

We go beyond just manufacturing parts. To streamline your supply chain, we offer light assembly services for your conductive components. This includes installing Helicoil inserts, pressing in pins, and assembling RF connector housings with insulators.

If your project involves multi-material systems, we can also integrate these conductive parts into larger builds, similar to our custom CNC machining services for machinery and robotics parts. This factory-direct approach reduces handling time and ensures your parts arrive ready for final installation.

Reviews

There are no reviews yet.