Why Choose ZSCNC for Aerospace Component Machining

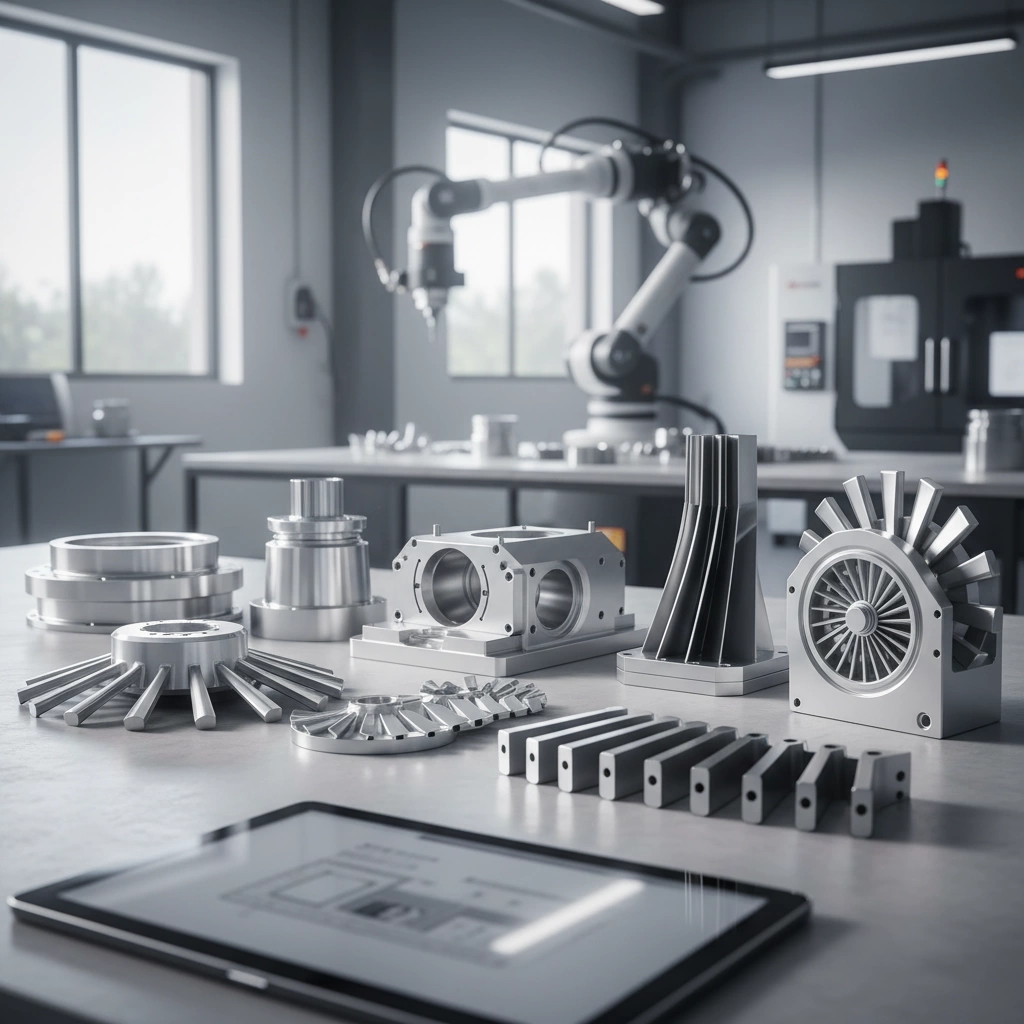

Sourcing reliable aerospace precision parts often involves navigating slow supply chains and rigid minimum order quantities. We understand that in the aerospace industry, a delay in a single bracket or housing can ground an entire testing schedule. At ZSCNC, we eliminate these bottlenecks by combining precision CNC machining aerospace capabilities with an agile manufacturing model designed for speed and accuracy.

We operate as your strategic partner, not just a job shop. Our facility is optimized to handle complex geometry aerospace machining with strict adherence to ISO 9001 quality standards, ensuring that every component meets the rigorous demands of flight-critical applications.

Operational Excellence & Strategic Advantages

We bridge the gap between rapid prototyping and scalable production. By leveraging our in-house fleet of 40+ CNC machines, we deliver flight-critical machined parts without the heavy upfront investment required by traditional manufacturing methods.

- Ultra-Fast Lead Times: We deliver prototypes in as little as 7 days. Our 24-hour quote turnaround ensures your engineering team isn’t left waiting.

- No Upfront Tooling Costs: Unlike casting or molding, our CNC processes require no expensive molds, allowing for cost-effective design iterations.

- Design-for-Manufacturability (DFM): Our engineers review your CAD data immediately to identify potential machining risks, suggesting optimizations to reduce weight and cost before metal is cut.

- Global Logistics Expertise: We have established logistics channels for seamless delivery to the USA, Europe, and Japan, managing all shipping documentation to prevent customs delays.

ZSCNC vs. Traditional Machine Shops

| Feature | ZSCNC Capabilities | Traditional Aerospace Shops |

|---|---|---|

| Lead Time | 7 Days (Rapid Prototyping) | 4–8 Weeks |

| Batch Size | Flexible (1 to 1000+ parts) | High MOQs often required |

| Quoting Speed | 24 Hours | 3–5 Business Days |

| Process Control | End-to-End (Machining to Finishing) | Often Outsourced |

| Focus | High-precision aerospace parts | General Machining |

Our proven track record involves manufacturing high-precision components for critical applications where failure is not an option. Whether you need aerospace structural brackets or intricate engine components, our workflow ensures full traceability and dimensional accuracy from the first cut to final inspection.

Core Capabilities & Machining Processes for Aerospace

To deliver flight-critical machined parts, you need more than just standard equipment. At ZSCNC, we have optimized our shop floor to handle the rigorous demands of the aerospace industry. We combine advanced automation with skilled craftsmanship to produce aerospace precision parts that meet strict geometric tolerances.

Our manufacturing ecosystem is built to handle everything from rapid prototyping to full-scale production runs:

- 5-Axis Simultaneous Milling: We utilize 5-axis CNC aerospace components manufacturing to machine complex shapes in a single setup. This reduces handling errors and ensures superior positional accuracy for complex geometry aerospace machining, such as turbine blades and impellers.

- High-Speed Turning & Swiss Machining: Our Aerospace CNC milling turning capabilities cover everything from large cylindrical housings to microscopic pins. Swiss-style machining allows us to produce long, slender parts with zero deflection, ensuring high precision.

- EDM Precision: For features that are impossible to cut with traditional tools, we use Wire and Sinker EDM. This is essential for working with hardened alloys and creating internal corners with extremely tight radii.

- Integrated Secondary Processes: We offer a complete solution. Beyond chip removal, we integrate processes like stamping and precision laser cutting services to finish structural elements and sheet metal components, delivering parts that are ready for final assembly.

Materials Expertise for Aerospace Parts

At ZSCNC, we understand that material selection is critical for flight hardware performance. We process a wide range of certified materials designed to withstand extreme thermal cycles and mechanical stress while meeting strict weight reduction targets. Our supply chain ensures full traceability for every billet and block we machine.

High-Performance Alloys

We specialize in machining hard metals that demand rigid setups and specialized tooling. Our team delivers precision results with:

- Titanium: We provide expert aerospace titanium machining, focusing on Grade 5 (Ti-6Al-4V) for its superior strength-to-weight ratio and corrosion resistance.

- Superalloys: We handle Inconel and Hastelloy for engine components requiring high thermal stability and fatigue resistance.

- Stainless Steel & Aluminum: From 17-4PH stainless to 7075 aluminum, we cover standard structural requirements.

Lightweight Advanced Plastics

To help engineers reduce payload weight without sacrificing durability, we machine high-performance engineering plastics. Our capabilities include:

- PEEK: We manufacture complex PEEK aerospace components known for their excellent chemical resistance and high melting points.

- Other Polymers: We also work with PEI (Ultem), PPS, and Torlon for interior parts and insulators.

Precision Standards for Aerospace Component Machining

In the aerospace sector, precision is critical for safety and performance. We specialize in manufacturing high-precision aerospace parts that strictly adhere to rigorous engineering specifications. Our facility is optimized to deliver tight tolerance aerospace components (±0.01mm), ensuring every feature aligns perfectly within the final assembly.

To maintain this level of exactness, we follow strict industrial-grade CNC machining accuracy standards, utilizing advanced metrology equipment for verification.

Key Quality Controls

- Micron-Level Accuracy: We achieve exceptional dimensional stability for complex geometry aerospace machining, ensuring reliability in flight-critical hardware.

- Surface Finish Control: We monitor Ra values closely to ensure optimal aerodynamic performance and precise component mating.

- GD&T Mastery: Our team applies Geometric Dimensioning and Tolerancing to strictly control flatness, concentricity, and true position.

- Thermal Management: We implement specialized cutting strategies to mitigate thermal deformation and distortion, particularly when machining heat-sensitive alloys like Titanium.

Typical Aerospace Components We Manufacture

At ZSCNC, we specialize in producing aerospace precision parts that meet the rigorous demands of the aviation industry. Our facility is equipped to handle complex geometries and tight tolerances, ensuring every part fits seamlessly into your assembly. Whether you need flight-critical hardware or interior fittings, we deliver consistent quality across these key categories:

- Engine Components: We machine high-durability parts such as housings, brackets, and shafts. These components are crafted to withstand high temperatures and stress, often utilizing tough materials like Titanium and Inconel.

- Structural Elements: Weight reduction is critical in aerospace. We utilize our 5-axis CNC machining services for complex aluminum parts to produce lightweight thin-wall parts and complex plates that maintain structural integrity while minimizing mass.

- Flight Control & Hydraulic Mechanisms: Our team manufactures precision components for flight control systems and hydraulic units. We ensure micron-level accuracy for these moving parts to guarantee reliable operation and safety.

- Interior & Avionics Hardware: We also supply precision hardware for avionics enclosures and cabin interiors, ensuring exact fitment for electronic systems and passenger interfaces.

Quality Assurance & Industry Standards

At ZSCNC, we understand that reliability is non-negotiable when manufacturing flight-critical machined parts. Our quality management system is built to meet the rigorous demands of the global aerospace sector, ensuring every component we ship meets exact specifications. We are fully ISO 9001 certified, providing a solid framework for consistent quality control and operational excellence.

Rigorous Inspection & Verification

We don’t leave precision to chance. Our facility is equipped with advanced metrology tools, including CMM (Coordinate Measuring Machines), to perform 100% verification on complex geometries. Whether it is a single prototype or a production run, we ensure micron-level aerospace machining accuracy through strict inspection protocols.

- In-Process Inspection: Real-time monitoring during machining to prevent deviations.

- Final Verification: Comprehensive dimensional checks using CMM and optical measurement systems.

- Surface Analysis: Verification of Ra values and surface integrity.

Traceability & Material Compliance

Supply chain transparency is vital for aerospace precision parts. We provide full traceability for all materials, from raw stock to the finished component. Our team assists in verifying material properties, ensuring that the alloys and plastics used match your engineering requirements. For detailed insights on choosing the right substrate, our guide on how to select precise CNC machining materials outlines the critical factors for performance and durability.

We provide comprehensive documentation packages, including:

- Material Certifications (Mill Certs)

- Certificate of Conformance (CoC)

- Inspection Reports

- Heat Treatment & Surface Finish Reports

By strictly adhering to these standards, we deliver high-precision aerospace parts that integrate seamlessly into your assembly lines, minimizing risk and maximizing performance.

Production Scalability & Lead Times

Scaling up shouldn’t be a headache. At ZSCNC, we bridge the gap between initial R&D and full-scale manufacturing. We are built to handle Aerospace Component Machining projects of any size, offering true flexibility for your supply chain. Whether you are developing a new drone or upgrading legacy aircraft systems, our shop floor adapts to your volume needs.

From Prototype to Production

We don’t just chase million-part orders. We specialize in precision CNC machining aerospace projects starting from a single unit.

- Prototyping (1–50 pcs): Perfect for design validation, fit checks, and functional testing.

- Medium-Volume: Seamless transition to larger batches without the need to re-qualify a new vendor.

- High-Mix, Low-Volume: Ideal for specialized flight-critical machined parts where customization is key.

Streamlined 4-Step Workflow

Time is critical in aviation. We have stripped away unnecessary bureaucracy to establish a simple, effective process: Drawing → Quote → Manufacturing → Delivery. This clarity and efficiency are essential when you want to safely work with a CNC machining supplier to meet tight project deadlines. We keep communication direct and transparency high throughout the entire cycle.

Rapid Turnaround Strategies

We achieve ultra-fast lead times by optimizing our CAM programming and utilizing 5-axis CNC aerospace components setups. This reduces the number of fixture changes required, significantly cutting down machine time. We deliver aerospace precision parts quickly without ever compromising on the strict tolerances (±0.001mm) or surface finish requirements essential for airworthiness.

Engineering & Design Support

We go beyond simple production by acting as an extension of your engineering team. Before a single cutter touches metal, we perform a rigorous Design for Manufacturability (DFM) review on every file. This process identifies potential machining risks, tight tolerance conflicts, or geometry issues that could delay production or inflate costs.

Our goal is to optimize your aerospace precision parts for both performance and budget. We provide actionable feedback on:

- Material Selection: Recommending the right balance of weight and strength, whether you need lightweight aluminum alloys or corrosion-resistant stainless steel grades.

- Cost Optimization: Suggesting minor design tweaks that significantly reduce machining time without compromising functionality.

- Digital Integration: We maintain full CAD/CAM compatibility to ensure the digital thread remains unbroken from your original design file to the final inspection report.

By catching issues early, we ensure your custom aerospace components move from digital concept to flight-ready hardware smoothly and efficiently.

Case Studies: Aerospace Project Highlights

We believe the best way to demonstrate our capabilities is through the results we deliver. Our team regularly tackles complex geometry aerospace machining projects that other shops turn away, ensuring flight-critical machined parts meet the strictest safety and performance standards.

Overcoming Challenges with Thin-Wall Titanium Brackets

One of our most significant successes involved manufacturing aerospace structural brackets from Titanium (Ti-6Al-4V). The primary challenge was the part’s thin-wall design, which is prone to vibration and deformation during the cutting process.

- The Challenge: Maintaining geometric integrity while removing significant material volume.

- The Solution: We utilized our advanced 5-axis CNC aerospace components workflow to optimize tool paths and minimize cutting stress.

- The Result: We achieved tight tolerance aerospace components (±0.01mm) with zero distortion, delivering the verified batch within just 10 days.

Success Stories in High-Temp Alloy Housings

For a recent engine component project, we manufactured housings requiring extreme heat resistance. This involved machining tough superalloys that demand specialized tooling to prevent work hardening. While we frequently manage high-temperature plastic parts like PEEK for interior applications, this project focused heavily on metal durability under thermal stress.

- Process: We combined high-speed turning with Wire EDM to cut intricate internal features without compromising the material’s integrity.

- Outcome: The housings passed 100% CMM verification, proving our ability to handle micron-level aerospace machining for critical applications.

Frequently Asked Questions (FAQs)

What certifications does ZSCNC hold for aerospace manufacturing?

We operate under a rigorous ISO 9001 certified quality management system. Our facility is equipped to handle the strict requirements of aerospace precision parts, ensuring that every component meets micron-level accuracy and specific industry standards. We implement comprehensive inspection protocols to guarantee reliability for critical applications.

Can you machine exotic materials like Inconel and Titanium?

Yes, we specialize in aerospace titanium machining and working with difficult-to-machine alloys. Our capabilities include processing Titanium (Ti-6Al-4V, Grade 2), Stainless Steel, and other high-performance metals essential for flight-critical machined parts. We also machine advanced engineering plastics like PEEK and Nylon for specialized applications. You can explore our full range of aerospace manufacturing services to see how we handle these complex materials.

What is the standard lead time for prototype aerospace components?

Speed is one of our core strengths. We can deliver rapid prototypes in as little as 7 days. Our streamlined workflow, from 24-hour quoting to final production, allows us to support engineering firms with quick iterations and small batch customization without delays.

Do you provide First Article Inspection (FAI) reports?

Absolutely. We provide full traceability documentation and detailed inspection reports for all custom aerospace components. Our quality assurance process includes thorough verification to ensure that every part matches your exact specifications and geometric tolerances before shipment.

Reviews

There are no reviews yet.