Why Trust Our 5-Axis Machining Services?

Are you tired of receiving parts that are slightly out of spec? Worried that your complex designs will result in massive delays or exorbitant costs? We understand the frustration of dealing with shops that can’t handle intricate features. Our 5 axis machining services for complex aluminum and stainless parts are designed to eliminate these headaches, delivering precision and reliability for the global market.

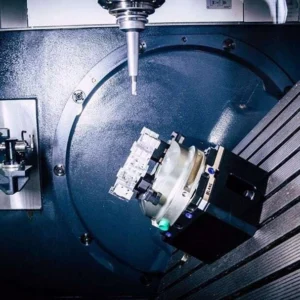

Solving Complex Geometry Challenges

Standard 3-axis machines often hit a wall when facing undercuts, deep cavities, or organic shapes. We utilize simultaneous 5-axis milling to move the cutting tool along five different axes at once. This allows us to machine complex geometry components—like impellers and turbine blades—without the need for multiple heavy fixtures. If you can design it, we can likely machine it.

Achieving Tighter Tolerances (±0.01 mm)

Precision is non-negotiable in aerospace and medical sectors. Every time a part is moved from one machine to another, accuracy is lost. By keeping the workpiece stationary while the tool moves, we achieve superior tight tolerance machining. We consistently hold tolerances as tight as ±0.01 mm, ensuring your parts fit perfectly every time.

Faster Turnaround with Single-Setup Machining

Time is your most valuable asset. Our process relies on single-setup machining, meaning we machine all sides of a part in one go. This approach offers significant benefits:

- Reduced Lead Times: No waiting for multiple setups or fixture changes.

- Lower Error Rates: Eliminates cumulative errors caused by manual re-clamping.

- Efficiency: Ideal for both rapid prototyping services and full-scale production.

Factory-Direct Pricing Advantage

You shouldn’t have to overpay for quality. As a dedicated ISO 9001 certified machine shop, we offer a factory-direct pricing model. By cutting out the middleman and optimizing our precision CNC manufacturing workflows, we provide high-end results at competitive rates. You get the technical capability of a top-tier facility without the inflated costs.

Specialized Aluminum 5-Axis Machining

We leverage over 15 years of industry experience to deliver high-precision 5 axis machining services for complex aluminum and stainless parts. Our facility is equipped to handle the unique properties of aluminum, ensuring high material removal rates without compromising on surface quality or dimensional accuracy.

High-Speed Milling for Aerospace Grades (7075, 6061)

Aluminum is the backbone of lightweight engineering. We utilize simultaneous 5-axis milling to process standard and high-performance alloys, including Aerospace grade aluminum 7075, 6061, 2026, and 5052. By manipulating the cutting tool along five axes simultaneously, we can machine deep pockets and intricate undercuts that 3-axis machines simply cannot reach.

- Material Integrity: Minimized heat buildup reduces warping in thin-walled parts.

- Precision: Tolerances as tight as +/- 0.01 mm are consistently achieved.

- Speed: Optimized tool paths allow for faster cycle times on complex geometries.

Applications: Heat Sinks and Drone Components

Our multi-axis contouring capabilities are essential for parts requiring sophisticated thermal and aerodynamic properties. We routinely manufacture complex geometry components for the aerospace and electronics sectors.

- Heat Sinks: Machining complex fin patterns and angled cooling channels in a single setup for maximum thermal efficiency.

- Drone Frames: Producing lightweight, structural components with organic curves.

- Prototyping: Just as medical device startups choose CNC machining for prototypes for critical testing, our aerospace clients rely on our 3–7 day turnaround for functional aluminum prototypes.

Surface Finishes for Aluminum Parts

A machined part isn’t finished until it meets your aesthetic and functional requirements. We offer a full range of in-house surface finishing options specifically for aluminum to enhance corrosion resistance and wear.

- Anodizing (Type II & III): Available in various colors for protection and cosmetic appeal.

- Bead Blasting: Creates a uniform matte texture, hiding tool marks.

- Chromate Conversion (Alodine): Maintains electrical conductivity while providing corrosion resistance.

- Powder Coating: Durable finish for exterior applications.

Heavy-Duty Stainless Steel 5-Axis Machining

We specialize in 5 axis machining services for complex aluminum and stainless parts, specifically tackling the hardness and durability requirements of steel alloys. While aluminum is lightweight, stainless steel offers the strength and heat resistance needed for critical applications. Our facility is equipped to handle the increased cutting forces required for these dense materials without compromising on speed or precision.

Handling Tough Alloys (304, 316, 17-4 PH)

Machining stainless steel requires rigid setups and advanced tooling strategies. We process a wide range of grades to meet specific mechanical properties:

- 304/304L: The standard for general enclosures and structural components.

- 316/316L: Essential for environments requiring high corrosion resistance.

- 17-4 PH: A precipitation-hardening grade used when high strength and hardness are non-negotiable.

We have optimized our processes for machining stainless steel to ensure consistent quality, whether you need a single prototype or a full production run.

Medical and Marine Industry Applications

Industries like medical and marine demand tight tolerance machining and superior surface finishes. In the medical field, we produce surgical instruments and implants that require bio-compatibility and intricate, organic shapes. For marine and harsh industrial environments, our Stainless steel 316 machining capabilities ensure parts resist saltwater corrosion and oxidation while maintaining structural integrity.

Combating Work-Hardening and Tool Wear

One of the biggest challenges with stainless steel is its tendency to work-harden if cut improperly. Our simultaneous 5-axis machines allow for multi-axis contouring that maintains optimal cutter engagement angles. This approach reduces heat buildup and prevents the material from hardening during the cut.

- Extended Tool Life: Proper engagement reduces wear, keeping costs down.

- Thermal Stability: Minimizing heat ensures complex geometry components stay within ±0.01 mm tolerance.

- Surface Integrity: Prevents surface micro-cracking and ensures a smooth finish ready for passivation or electropolishing.

Technical Capabilities and Equipment Specs

We invest heavily in advanced technology to deliver top-tier 5 axis machining services for complex aluminum and stainless parts. Our facility is equipped to handle the most demanding geometries, ensuring that your designs are manufactured exactly as intended without compromise.

Simultaneous 5-Axis vs. 3+2 Machining

Understanding the difference between these methods helps us optimize your production costs and lead times. We utilize both strategies depending on the complexity of your complex geometry components.

- Simultaneous 5-Axis Milling: The cutting tool and the workpiece move along all five axes at the same time. This is critical for multi-axis contouring, such as machining impellers, turbine blades, and organic shapes where smooth curves are non-negotiable.

- 3+2 Machining (Positional 5-Axis): The machine locks the part at a specific angle before cutting. This provides extreme rigidity and is ideal for features like angled holes or pockets on flat surfaces. It allows us to produce CNC production parts faster by utilizing shorter, stiffer tools.

Maximum Part Dimensions and Work Envelope

Our shop floor is versatile. We handle everything from micro-sized electronics housings to heavy-duty industrial components. As a dedicated custom aluminum CNC machining parts supplier, we ensure our work envelope accommodates a wide variety of project requirements.

Typical Machine Specifications:

| Feature | Specification Range |

|---|---|

| Max X-Axis Travel | Up to 1,200 mm |

| Max Y-Axis Travel | Up to 800 mm |

| Max Z-Axis Travel | Up to 600 mm |

| Table Load Capacity | Up to 500 kg |

| Spindle Speed | 12,000 – 24,000 RPM |

| Accuracy | ±0.01 mm |

Compatible CAD File Formats

To start your project, we need accurate 3D data. Our engineering team uses industry-standard CAM software to read your files directly, reducing translation errors and speeding up the programming phase for single-setup machining.

Preferred Formats:

- STEP (.stp, .step): Best for universal compatibility.

- IGES (.igs, .iges): Good for surface geometry.

- Parasolid (.x_t): Ideal for complex solid models.

- Native Files: SolidWorks (.sldprt), Inventor (.ipt), and CATIA.

Quality Control and ISO Certification

When you invest in 5 axis machining services for complex aluminum and stainless parts, you aren’t just buying metal parts; you are buying certainty. As an ISO 9001 certified machine shop, we treat quality assurance as the backbone of our manufacturing process, not an afterthought. We understand that a single deviation in tight tolerance machining can compromise an entire assembly, which is why we employ a rigorous, multi-stage inspection protocol.

In-Process Renishaw Probing

We don’t wait until the part is off the machine to verify accuracy. We utilize advanced in-process Renishaw probing to check critical dimensions while the component is still clamped. This allows us to:

- Automatically update tool offsets to compensate for wear.

- Verify datum points before cutting begins.

- Detect variations immediately, ensuring consistent precision CNC manufacturing across the entire batch.

CMM Verification for Complex Profiles

For complex geometry components with freeform surfaces—like impellers or turbine blades—standard measurement tools aren’t enough. We use Coordinate Measuring Machines (CMM) to map the physical part against the original CAD data. This validates that our 5-axis CNC machining capabilities have accurately reproduced even the most difficult contours and angles.

Material Certifications and FAI Reports

Traceability is non-negotiable for high-stakes industries. We provide comprehensive documentation to ensure your parts meet all regulatory standards:

- Material Certifications: Proof of authenticity for raw materials, whether it’s aerospace-grade aluminum or medical-grade stainless steel.

- First Article Inspection (FAI): A detailed report verifying that the first part produced meets every specification before full production runs.

- Heat Treatment & Finishing Reports: Validation for any secondary processes applied to the parts.

FAQs About 5-Axis CNC Services

Difference Between 5-Axis and 3-Axis?

The core difference lies in movement and efficiency. While 3-axis machines move linearly along the X, Y, and Z axes, simultaneous 5-axis milling adds two rotational axes (A and B). This allows the cutting tool to approach the workpiece from virtually any direction.

For you, this means single-setup machining. We don’t need to manually flip the part multiple times, which drastically reduces errors and improves precision for complex geometry components like turbines or medical implants.

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Movement | Linear (X, Y, Z) | Linear + Rotational (X, Y, Z, A, B) |

| Setups | Multiple required for complex shapes | Single setup for most parts |

| Accuracy | Cumulative error from re-fixturing | Higher precision (±0.01 mm) |

| Best For | Flat surfaces, simple holes | Multi-axis contouring, complex curves |

Can You Machine Hardened Stainless Steel?

Yes, we routinely handle tough materials. Our 5 axis machining services for complex aluminum and stainless parts are optimized for rigidity. We excel at stainless steel 316 machining for corrosion-resistant applications and handle hardened alloys like 17-4 PH without compromising surface finish. We also process aerospace grade aluminum 7075 for high-stress, lightweight components.

What Is the Lead Time for 5-Axis Parts?

Because 5-axis machining completes parts in fewer operations, we often deliver faster than shops using conventional methods. Typical lead times range from 1 to 2 weeks depending on complexity. If you are looking to optimize your schedule, we have specific strategies for reducing the delivery time of CNC components to get your products to market sooner.

Do You Handle Prototypes and Production Runs?

We support your project from concept to mass production. We offer rapid prototyping services to verify designs quickly using CNC turn-mill services. Once the design is locked, we scale up to CNC production parts with consistent repeatability. As an ISO 9001 certified machine shop, we guarantee that the quality of the 1,000th part matches the first prototype.

Reviews

There are no reviews yet.