PTFE High Performance Plastic Overview

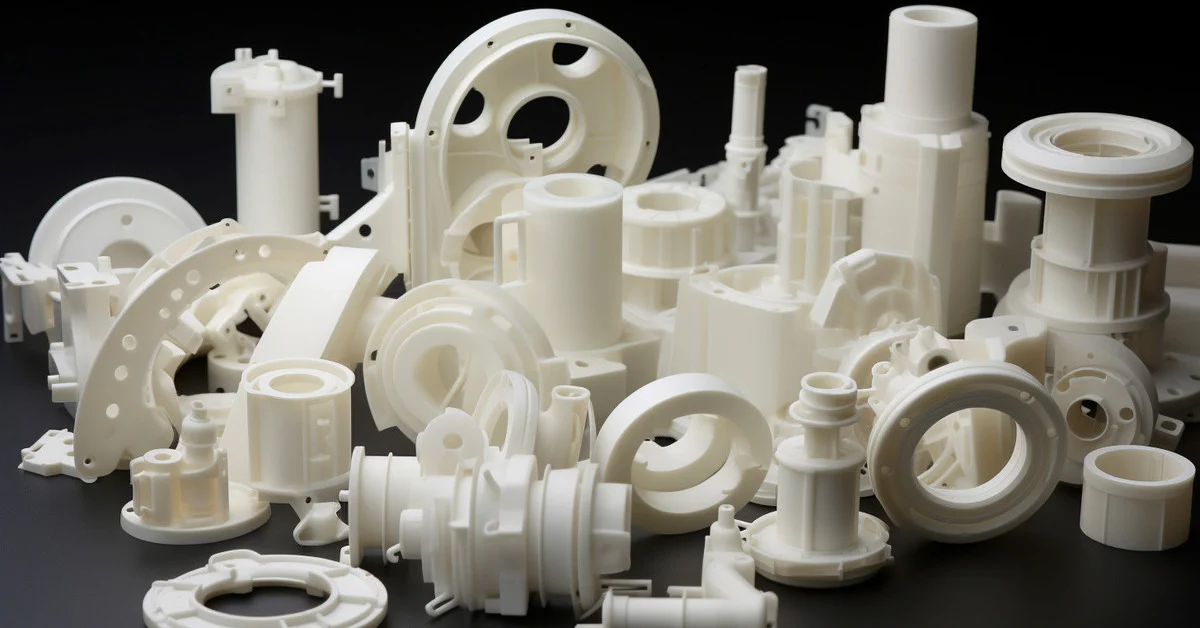

Explore ZSCNC’s expertise in precision machining of PTFE, a versatile polymer known for chemical resistance, low friction, and thermal stability.

Our advanced CNC capabilities enable complex shapes with tight tolerances, ideal for aerospace, medical, and industrial applications. Learn more about our wide range of plastic materials.

Core Material Characteristics of PTFE

PTFE offers a non-adherent surface with superior chemical resistance, excellent electrical insulation, a broad temperature range, and a low friction coefficient. These features make it the ideal choice for demanding industrial applications.

Non Adherent Surface

PTFE’s low surface energy prevents material sticking, improving operational efficiency.

Superior Chemical Resistance

Highly resistant to aggressive chemicals, ensuring durability in harsh environments.

Excellent Electrical Insulation

Outstanding electrical insulating properties maintain safety and performance.

Broad Temperature Range

Performs reliably across extreme temperatures from -200°C to +260°C.

Low Friction Coefficient

Minimizes wear and extends lifespan in dynamic applications.

PTFE CNC machined Parts & Typical Application Categories

Chemical Process & Fluid Control Components

Precision PTFE parts ensure outstanding chemical resistance and durability in fluid control systems, often requiring CNC milling for accurate shaping.

Laboratory & Analytical Instrument Parts

High-tolerance PTFE components deliver reliability and purity essential for lab and analytical tools, manufactured with precision CNC turning.

Electrical & Electronic Insulation Parts

PTFE’s excellent dielectric properties provide safe, long-lasting insulation in electronic applications.

Low Friction Sliding Components

PTFE machined parts reduce friction and wear, improving performance and longevity in moving assemblies, often produced by advanced five-axis CNC machining.

PTFE CNC Machining Expertise

Dedicated Equipment for PTFE

ZSCNC utilizes specialized CNC machinery designed specifically for PTFE materials, ensuring precision and minimizing contamination risk.

Specialized Process Controls

Our advanced process controls monitor temperature, speed, and tool pressure for consistent high-quality PTFE milling results.

Dimensional & Form Accuracy

We achieve micron-level dimensional tolerances with rigorous inspection protocols, ensuring parts meet demanding specifications.

Surface Finish & Deburring

Our finishing processes deliver smooth, burr-free surfaces optimized for PTFE applications, enhancing part performance and durability through expert CNC turning.

PTFE Material Selection and Design Recommendations

Ideal Conditions for PTFE

PTFE excels in environments demanding extreme chemical resistance and high temperature tolerance. Optimal performance occurs within -200°C to 260°C.

Structural Design Advice

Incorporate allowance for PTFE's thermal expansion and low mechanical strength. Use robust supports and avoid sharp corners to prevent stress concentration.

Fit and Assembly Tips

Design mating components with loose tolerances to accommodate PTFE's creep and cold flow. Use mechanical fasteners to ensure consistent assembly strength.

Performance vs Cost Balance

Optimize component size and complexity to reduce machining time. Prioritize critical PTFE properties to control costs without compromising functionality.

At ZSCNC, we deliver expert support in PTFE material selection and precision machining tailored to your design and budgetary needs.

Quality Control and International Customer Validation

Raw Material Inspection

Ensure premium quality with rigorous raw material inspections, complying with global standards.

Process Monitoring

Continuous process monitoring guarantees consistency and reduces defects throughout production.

Final Inspection and Documentation

Comprehensive final inspections with detailed documentation assure transparency and customer confidence.

Proven Export Experience

ZSCNC leverages years of export expertise, ensuring seamless international compliance and delivery.

PTFE Custom Project Workflow

1. Requirements Communication and Drawing Review

Collaborate closely to define detailed PTFE project specifications. Our experts review drawings to ensure manufacturability and precision, following strict quality control standards.

2. Process Planning and Quote

Develop customized production plans. Receive transparent and competitive quotes reflecting project complexity and timelines, using insights from our manufacturing process.

3. Prototype and Confirmation

Produce precise PTFE prototypes for validation. Confirm specifications and quality before proceeding to mass production.

4. Mass Production and Delivery

Execute large-scale PTFE production efficiently, meeting quality standards and delivery schedules with expert handling. Our facility details are available in the factory tour.