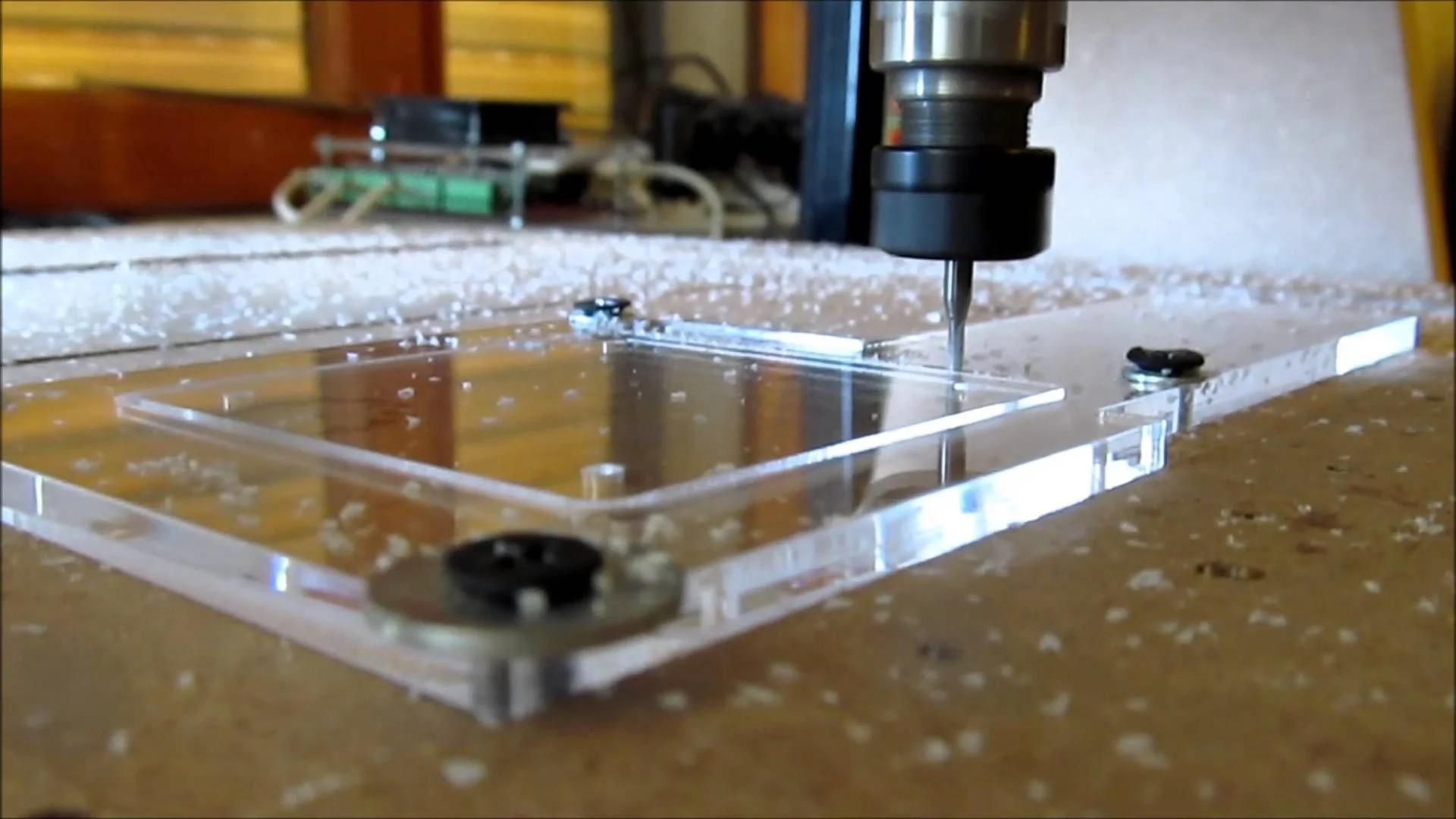

Acrylic Precision Transparent Plastic Processing Service

ZSCNC delivers high-accuracy acrylic machining for flawless transparent plastic parts. Our precision CNC processing ensures consistent tolerances and polished finishes.

Acrylic Material Characteristics

Acrylic offers high optical clarity, excellent weather resistance, and superior impact strength. Its versatility makes it ideal for a wide range of industrial and commercial materials uses.

- Lightweight yet durable with good mechanical properties

- Excellent UV and chemical resistance for outdoor applications

- High scratch resistance and easy to fabricate by CNC machining

- Transparent and highly polished surface with superior aesthetics

Suitable Applications

Ideal for signage, display cases, machine guards, lighting fixtures, and protective barriers. Acrylic delivers high performance where clarity and durability are paramount.

Acrylic Precision CNC Machining Capabilities

At ZSCNC, our advanced CNC machining delivers intricate acrylic parts with unmatched precision. We specialize in tight tolerances and high surface quality for critical applications.

- Tolerance range: ±0.01 mm for high precision components

- Material options tailored for optical clarity and durability

- Consistent surface finish for aesthetic and functional excellence

Surface Quality and Post Processing Solutions for Transparency and Appearance

Precision Surface Finishing

Achieve flawless transparency with advanced polishing and sanding techniques, eliminating defects and improving optical clarity.

Specialized Coatings and Treatments

Enhance appearance and durability with coatings that resist scratches, UV damage, and discoloration for long-lasting aesthetics.

Optimized Post-Processing Workflows

Streamlined processes reduce lead times while maintaining quality, ensuring consistent surface quality across production runs. Learn more about our quality control standards and manufacturing process for optimized post-processing.

Design and Material Selection Guidance for Application Alignment

Strategic Design Alignment

Ensure design decisions directly support your application’s functional and aesthetic goals. Early-stage alignment reduces costly revisions and maximizes performance outcomes.

Material Selection for Durability

Choose materials specifically engineered to withstand operational stresses, environmental factors, and lifecycle requirements for optimal longevity.

Precision Manufacturing From ZSCNC

Leverage ZSCNC’s advanced processes to ensure tight tolerance control and consistent quality, minimizing variance and enhancing reliability.

Quality Control and Global Delivery Standards

Rigorous Quality Assurance

At ZSCNC, every product undergoes precise inspection to meet the highest industry standards. Our in-house testing protocols eliminate defects early, ensuring superior quality control and reliability.

Advanced Precision Manufacturing

Utilizing cutting-edge CNC machining technology, we maintain microscopic tolerances, guaranteeing consistent quality in every batch produced.

Compliance with Global Standards

Our processes align with international regulations to ensure seamless delivery and acceptance across global markets, backed by documented quality certifications.

Timely and Secure Global Delivery

ZSCNC leverages optimized logistics networks guaranteeing prompt and secure shipment worldwide, reducing lead times and improving supply chain reliability.

Project Collaboration Workflow for Acrylic Precision Parts

1. Initial Consultation & Design Review

Discuss project requirements with ZSCNC experts to ensure precise specifications for acrylic parts. For more details on our focused approach, visit our about page. Collaborative design review eliminates ambiguities early.

2. Prototype Development & Approval

Rapid prototyping using CNC machining provides tangible samples. Receive prompt feedback to expedite design optimization and final approval.

3. Precision Manufacturing & Quality Control

Advanced CNC equipment ensures flat tolerances and consistent quality. Rigorous inspection guarantees every acrylic part meets exacting standards through our quality control processes.

4. Delivery & Ongoing Support

Timely shipment with secure packaging protects parts. ZSCNC offers continuous technical support for integration and future project scaling.