Robotics: Your Premier CNC Machining Service Provider

ZSCNC delivers high-impact banner modules designed to boost user engagement and enhance your marketing ROI effectively.

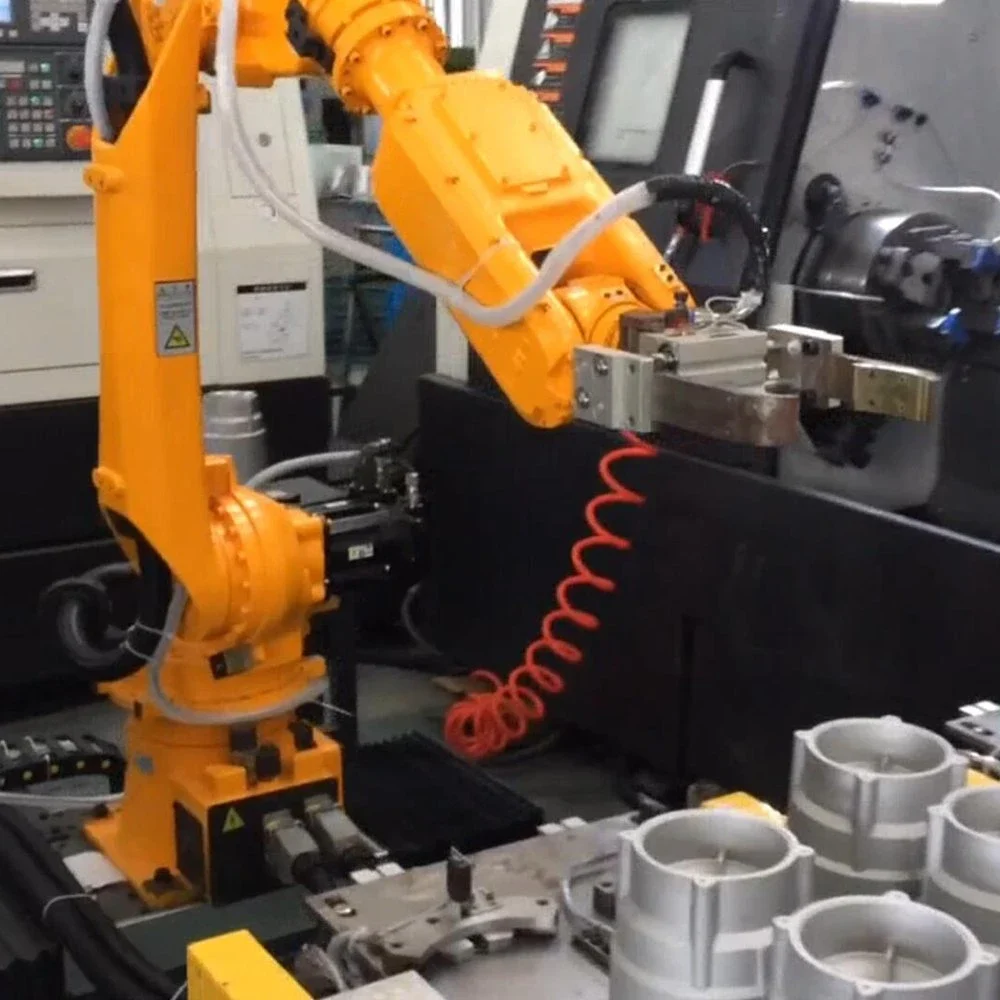

Robotics Precision CNC Machining for High Reliability Automation

Custom high precision robot components and core structure parts for automated equipment engineered for long term stable operation under complex conditions. Our CNC machining services ensure superior quality and durability.

- High precision CNC machining for robot joints, gearbox housings, and actuators

- Customized parts for collaborative robots, industrial robots, and automated production lines

- International standard quality management meeting EU, US, and Japan market requirements

- Flexible production schedules from small batch validation to medium scale volume manufacturing

Precision Range

Typical dimensional and form tolerance capabilities at micrometer level fits

Applicable Robot Types

Collaborative, material handling, welding, SCARA, AGV, AMR structural parts

Service Tags

DFM evaluation, prototype sampling, volume production, assembly fit control

Quality Standards

Compliance with EU, US, and Japan market quality management systems

Rapid feasibility and delivery assessments to support your automation production needs with expert milling services.

Robotics and Automation Specialized Components

Motion and Transmission Structures

Joint housings, link arms, swivel mounts, and installation flanges designed for maximum dimensional stability under repeated motions.

Gearbox seats, bearing supports, and transmission brackets focus on stiffness and precise positioning to ensure optimal robot performance achieved through CNC machining.

Actuation and End Effector Support Parts

Gripper bases, tool connection plates, and modular changeover blocks engineered to balance lightweight design with rigidity.

Custom mounts for welding, material handling, and assembly applications improve robot dynamics and operational flexibility, often requiring CNC milling precision.

Control and Protective Mechanical Components

Control cabinet frameworks, small servo module brackets, sensor mounts, and cable routing shields built for compact layouts.

Protective covers and rail mounting bases allow easy assembly and maintenance while ensuring robust protection.

Design and Manufacturing Highlights

Each component group reflects ZSCNC’s commitment to CNC precision and expert engineering tailored to robotics. We prioritize dimensional stability, stiffness, and ease of integration to meet the demanding requirements of automation systems.

Materials and Performance Solutions Tailored for Robotics

Structural and Load Bearing Parts

Medium to high strength alloy steels, quenched and tempered steels, and fatigue resistant steels are selected for superior fatigue life and torsional stiffness.

Focused on wear resistance of fastener holes, with post-processing options including heat treatment, surface hardening, and precision grinding. These parts often require advanced CNC machining to achieve tight tolerances and durability.

Lightweight and High Speed Movable Parts

Aluminum alloys and precision extrusions offer high strength with low weight, enabling rapid robotic movement.

Designs emphasize weight reduction without compromising critical cross sections or rigidity. Surface finishing options include anodizing, hard coat oxidation, and color coding for module differentiation. Precision milling machining is often applied to achieve the required detailing and finish.

Special Environment and Safety Relevant Components

Components exposed to welding spatter, dusty environments, or mild corrosion require stainless steel and specialized coatings for corrosion and wear resistance.

Material and coating combinations are optimized for durability and safety under challenging operational conditions. When complex shapes are required, turning machining techniques ensure precision and quality.

ZSCNC provides custom material and process combinations tailored for specific robotic applications, not generic part solutions.

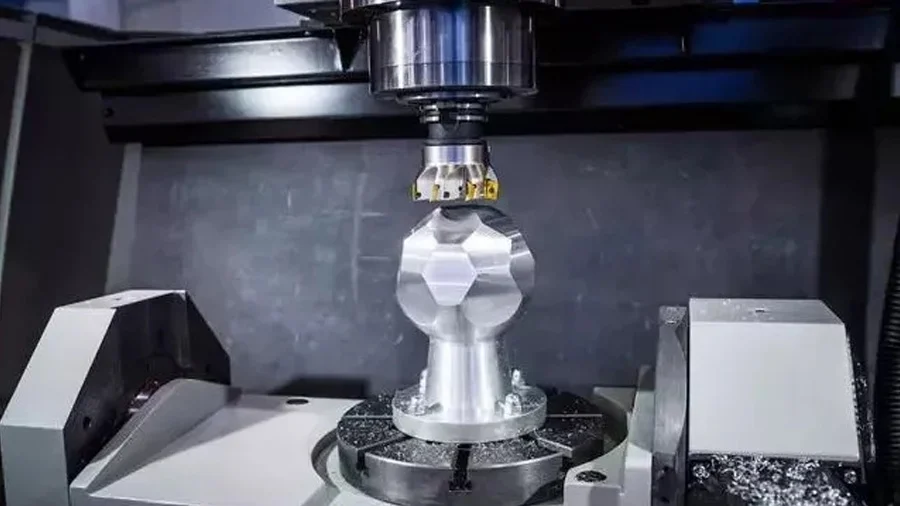

Precision & Process Capability

End-to-end quality assurance from design through shipment with dimensional repeatability and assembly interchangeability. Our expertise in CNC machining ensures high standards at every stage.

Robot Joint & Locating Face Precision

Design Checkpoint

- • Tight fitting control: Precise holes, keyways, and reference surfaces

- • Batch uniformity: Guaranteed interchangeability across multi-unit assemblies

- • Critical tolerance: ±0.01mm specifications for joint alignment

Complex Contour & Multi-Surface Machining

Production Checkpoint

- • Multi-axis capability: 3-5 axis five-axis machining for DOF joint parts

- • Spatial precision: Curved housings and angled mounting surfaces

- • Fixture optimization: Multi-station setup minimizes errors

Surface Quality & Operational Smoothness

Quality Checkpoint

- • Roughness control: Ra 0.4–1.6µm on sliding surfaces

- • Operational smoothness: Ensures efficient and reliable robot movement enabled by precise milling machining

Collaborative Project Delivery and Engineering Support for Robotics Development

Project Phases

Concept and Prototype Stage

Accepts 3D models and 2D drawings, providing manufacturability feedback specific to robotics structures.

- Wall thickness, chamfers, and assembly reference points

- Simplified machining steps

Supports limited pilot runs for functional prototype assembly and motion testing with advanced CNC machining services.

Engineering Validation and Small Batch Pilot Production

Progressive small batch deliveries matching project timelines to verify real-world performance.

- Iterative process optimizations including hole position tweaks and fit clearance adjustments

- Process data recorded to streamline volume production phase

Support Services

Stable Volume and Long Term Supply

Our services establish controlled process workflows and inspection criteria ensuring consistent quality.

- Production scheduling aligned with robotic project timelines and batch manufacturing needs

- Expertise familiar with robotic OEM and integrator project rhythms

Enables smooth scaling from prototype to production with reliability and precision, supported by industry-leading milling services.

Quality Assurance & International Excellence

Precision-driven quality processes and proven expertise serving global robotics manufacturers across EU, US, and Japanese markets.

Quality Process Control

Process Quality Management

- • Critical dimension checklists for robotic components

- • Comprehensive batch inspection records

- • Real-time process monitoring and control

Advanced Metrology & Calibration

- • Calibrated gauges for precision hole fits

- • Locating surface and assembly reference validation

- • Continuous tolerance refinement via feedback loops

Documentation & Traceability

- • Dimensional certificates and material certifications

- • Heat treatment and surface finish documentation

- • Long-term batch traceability for issue resolution

International Collaboration & Delivery Excellence

Global Client Base

Proven expertise serving demanding EU, US, and Japanese robotic manufacturers with customized solutions and exacting quality standards.

Technical Communication

Clear and effective collaboration processes ensuring alignment with international partners and adherence to project timelines.

Delivery & Logistics

Robust delivery systems addressing customs, packaging, and logistics challenges across key markets with expertise in laser-cutting manufacturing processes.

Typical Robotics and Automation Applications

Smart Manufacturing Production Automation

Multi-station assembly, material handling, and inspection robotic cells designed for 24/7 durability. Focused on cycle time stability, joint component life, assembly repeatability, and onsite maintenance ease.

- Robust designs ensuring consistent performance under continuous operation

- Optimized joint longevity to minimize downtime

- Streamlined assembly processes for high repeatability and quality

- Facilitated quick and effective onsite maintenance

Collaborative Robotics and Flexible Production Units

Human-robot collaboration with an emphasis on safety and lightweight mechanical design. Prioritizes surface finish quality, edge treatment, and quick-change end effector mounts, enhanced by precision CNC machining.

- Safety-first approach ensuring seamless human interaction

- Lightweight components for easy adaptability and flexibility

- High-quality finishes suitable for sensitive assembly processes

- Modular mounts enabling rapid tool changes and minimal downtime

Logistics and Warehouse Automation

AGV and AMR chassis with structural supports and sensor mounting brackets engineered for impact resistance. Designed for fatigue endurance and compact footprint optimization using specialized milling machining techniques.

- Durable chassis frames built to withstand harsh logistics environments

- Optimized structural supports for long life under continuous load

- Smart sensor mounts ensuring reliable operational feedback

- Compact designs maximizing warehouse space efficiency

Custom Structural Designs & Machining Priorities

ZSCNC delivers tailored structural parts crafted to your distinct robotic application needs. Enhance your automation solutions with competitive, durable, and precise manufacturing expertise, leveraging advanced turning machining capabilities.