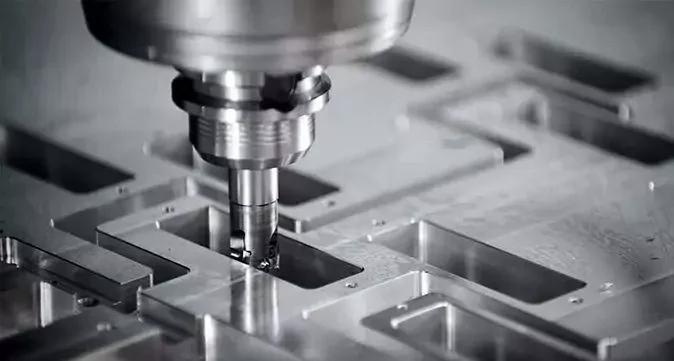

Precision CNC Machining

High-accuracy cutting for aerospace, automotive, and medical component fabrication to meet stringent industry standards.

Delivering precision manufacturing solutions that drive efficiency and product excellence through advanced technology and expert craftsmanship.

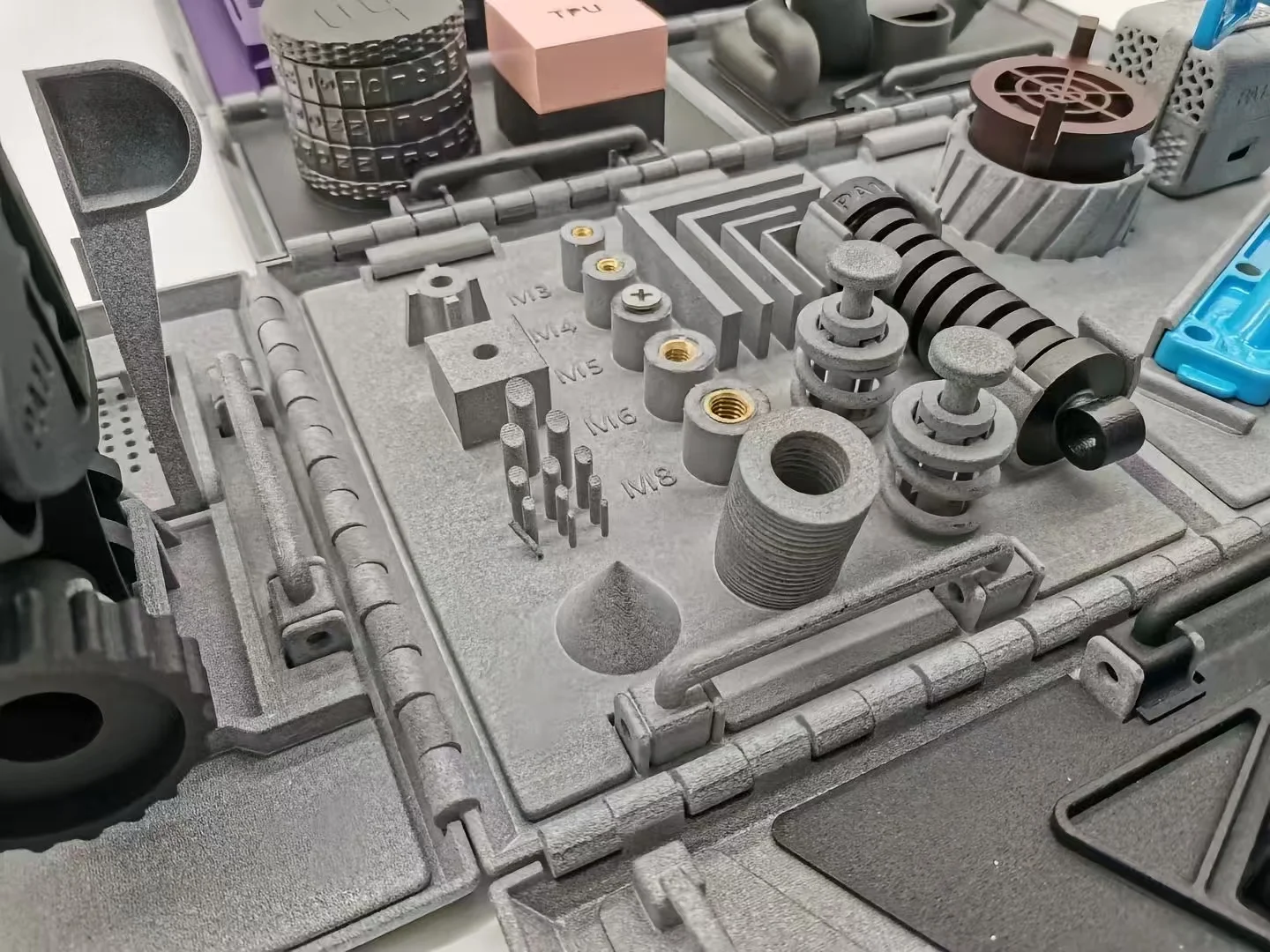

From design concept to functional parts, ZSCNC delivers rapid prototyping with unmatched precision.

Accelerate development cycles and validate your product concepts efficiently with our expert fabrication services.

Precision CNC machining services for EU automotive components and motorsport parts with tight tolerances ISO certification and fast delivery.

Precision CNC aluminum machining for high performance parts in Europe with ISO certified quality 5 axis capability fast delivery and tight tolerances

High precision CNC machining for packaging machinery parts with food grade materials and fast delivery to Netherlands and Belgium

Custom CNC machining supplier for automotive parts in Netherlands and Belgium offering precision prototypes low volume production and EUgrade quality

ZSCNC delivers precision metal forming and structural manufacturing from sheet metal to complex spatial assemblies. Our state-of-the-art technology and skilled engineering teams ensure scalable, high-quality production tailored to your exact specifications.

Discover the advantages and key differences between laser and waterjet cutting technologies in modern fabrication. Understand which method maximizes precision, efficiency, and material integrity.

Laser cutting uses a focused beam of light to precisely cut or engrave

materials, ideal for thin metals, plastics, and composites. It offers high

speed, excellent accuracy, and a clean edge finish without mechanical wear.

Waterjet cutting employs a high-pressure jet of water mixed with abrasive

materials to cut through a wide range of substances, including thick

metals and stone, while avoiding thermal distortion.

At ZSCNC, we provide expert guidance to select the optimal cutting technology based on your material, design complexity, and production timelines. Harness precision and consistency for your fabrication needs with our advanced laser and waterjet cutting solutions.

Our stamping workflow utilizes precision dies and automated presses for consistent, high-speed fabrication. This ensures tight tolerances and repeatable quality for mechanical parts at scale.

Through advanced mass forming techniques, we greatly reduce material waste while enhancing structural integrity. This enables cost-effective production without compromising durability.

Our rigorous inspection protocols leverage state-of-the-art metrology and inline monitoring to detect deviations early, ensuring parts meet all industry standards before shipment.

Maximize throughput, reduce lead times, and guarantee precision with our stamping and mass forming expertise tailored for high volume demand.

High-accuracy cutting for aerospace, automotive, and medical component fabrication to meet stringent industry standards.

Multi-industry sheet metal stamping and forming delivering durable, precise structural and component parts.

Complete end-to-end production solutions integrating design, fabrication, and quality control for enhanced efficiency.

Industry 4.0 solutions enhance fabrication with automated workflows, real-time monitoring, and adaptive control.

Advanced robotics deliver consistent assembly precision and component quality in demanding industrial environments.

Durable fabrication of large-scale structural parts for construction, energy, and infrastructure sectors. Learn more about our industry experience and expertise.

ZSCNC’s stepwise cooperation process streamlines engineering collaboration for superior project outcomes. Learn more about our manufacturing process.

Understand client goals, requirements, and constraints to set clear collaboration objectives.

Joint development of detailed designs, leveraging expertise to optimize functionality and cost.

Build and validate prototypes under rigorous standards to ensure reliability and compliance.

Align production plans and timelines for efficient resource allocation and on-time delivery.

Execute manufacturing with stringent quality controls to meet client specifications and standards.

Finalize project delivery and provide ongoing technical support to sustain partnership success.