Process Structure

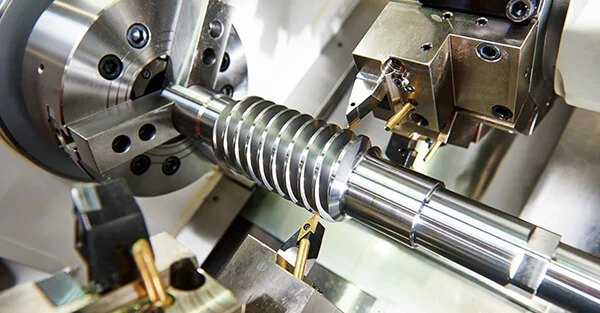

Swiss machining uses a sliding headstock, enabling continuous feed and multi-axis precision. Conventional CNC utilizes fixed spindles with batch processing. This machining process highlights core differences.

Experience unparalleled Swiss CNC precision turning with ZSCNC. Delivering high-accuracy components tailored to your industry needs.

Our advanced CNC processes ensure consistent quality, tight tolerances, and scalable production for medical, aerospace, and electronics sectors.

Swiss machining uses a sliding headstock, enabling continuous feed and multi-axis precision. Conventional CNC utilizes fixed spindles with batch processing. This machining process highlights core differences.

Swiss machining excels with small, complex, high-precision parts under 38mm diameter. Conventional CNC is preferred for larger, simpler geometries. For precise turning machining, Swiss machines excel.

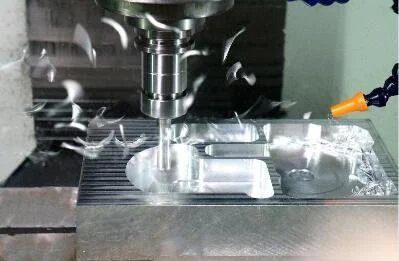

Swiss machining enables efficient continuous and high-volume production with minimal setup times. Conventional CNC suits batch production with frequent tool changes, including advanced five-axis machining.

Precision CNC machining services for EU automotive components and motorsport parts with tight tolerances ISO certification and fast delivery.

High precision CNC machining for packaging machinery parts with food grade materials and fast delivery to Netherlands and Belgium

Aluminum CNC milling service for German machinery parts with tight tolerances certified alloys fast delivery and custom prototypes

Custom CNC machining services for machinery and robotics parts with tight tolerances fast lead times and ISO certified quality

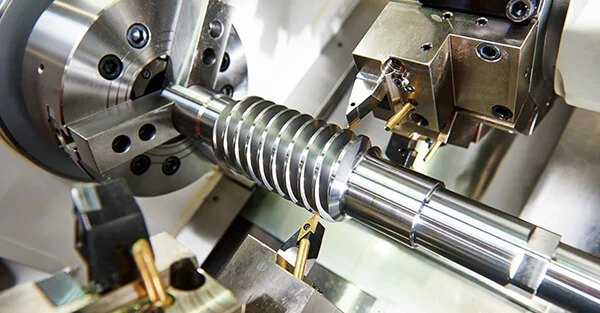

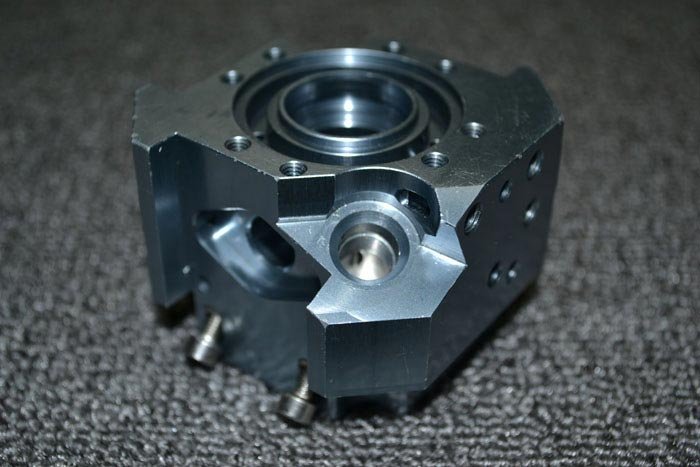

Precision machining supports diameters from sub-millimeter to medium scale, enabling diverse component fabrication.

Capable of handling parts up to 300 mm in length for complex applications requiring extended machining areas.

Maintains tight concentricity tolerances within ±0.002 mm, ensuring high-quality functional performance.

Achieves surface finishes down to Ra 0.1 μm with advanced tooling and process optimization.

Enables simultaneous turning, milling, and drilling for complex geometries in a single setup.

Supports a wide range of metals including stainless steel, titanium, brass, and aluminum alloys.

Drilling of micro holes as small as 0.1 mm with consistent positional accuracy and burr-free edges.

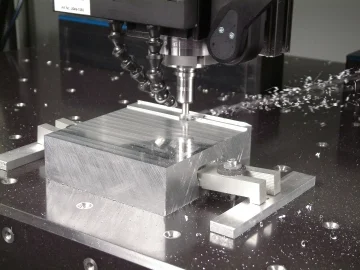

Advanced temperature compensation and real-time monitoring reduce dimensional drift during long runs.

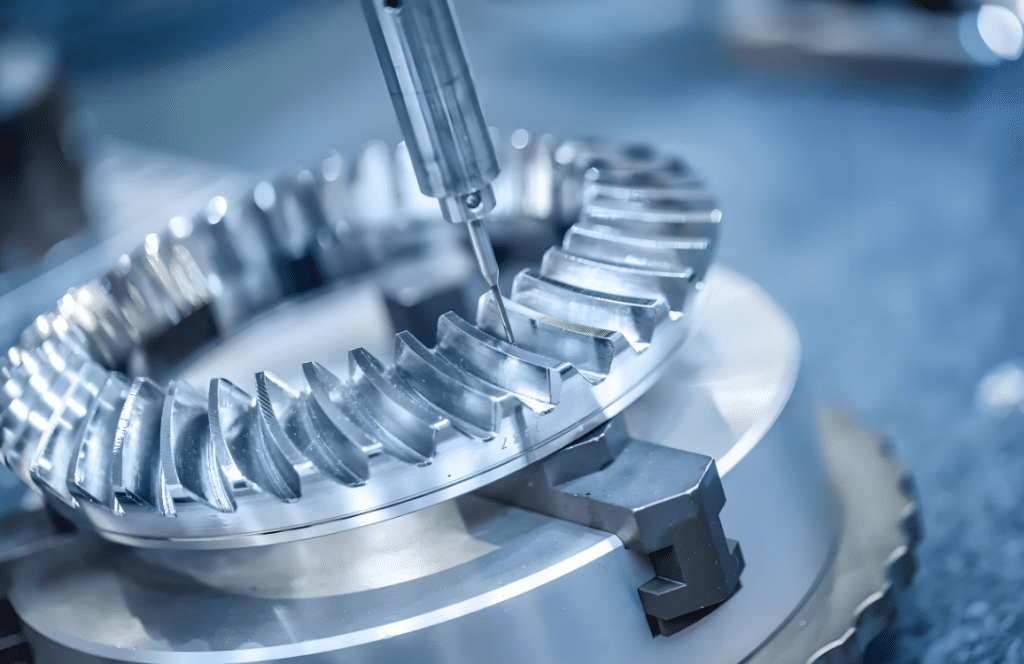

Precision-crafted micro shafts and pins designed for high-performance assemblies in medical devices and

electronics.

Ideal for applications demanding reliable rotational components with tight dimensional tolerances.

High-quality connectors and fasteners ensuring secure and exact engagements in aerospace and industrial

equipment.

Manufactured with dimensional accuracy and superior material strength to withstand demanding environments.

Durable miniature bushings and sleeves tailored for precision alignment and wear resistance in small-scale

mechanisms.

Suitable for robotics, instrumentation, and specialized manufacturing where tight clearance is critical.

Complex micro parts engineered for multifunctional performance in precision devices and medical applications.

Integrating multiple features with high accuracy to reduce assembly steps and enhance system reliability.

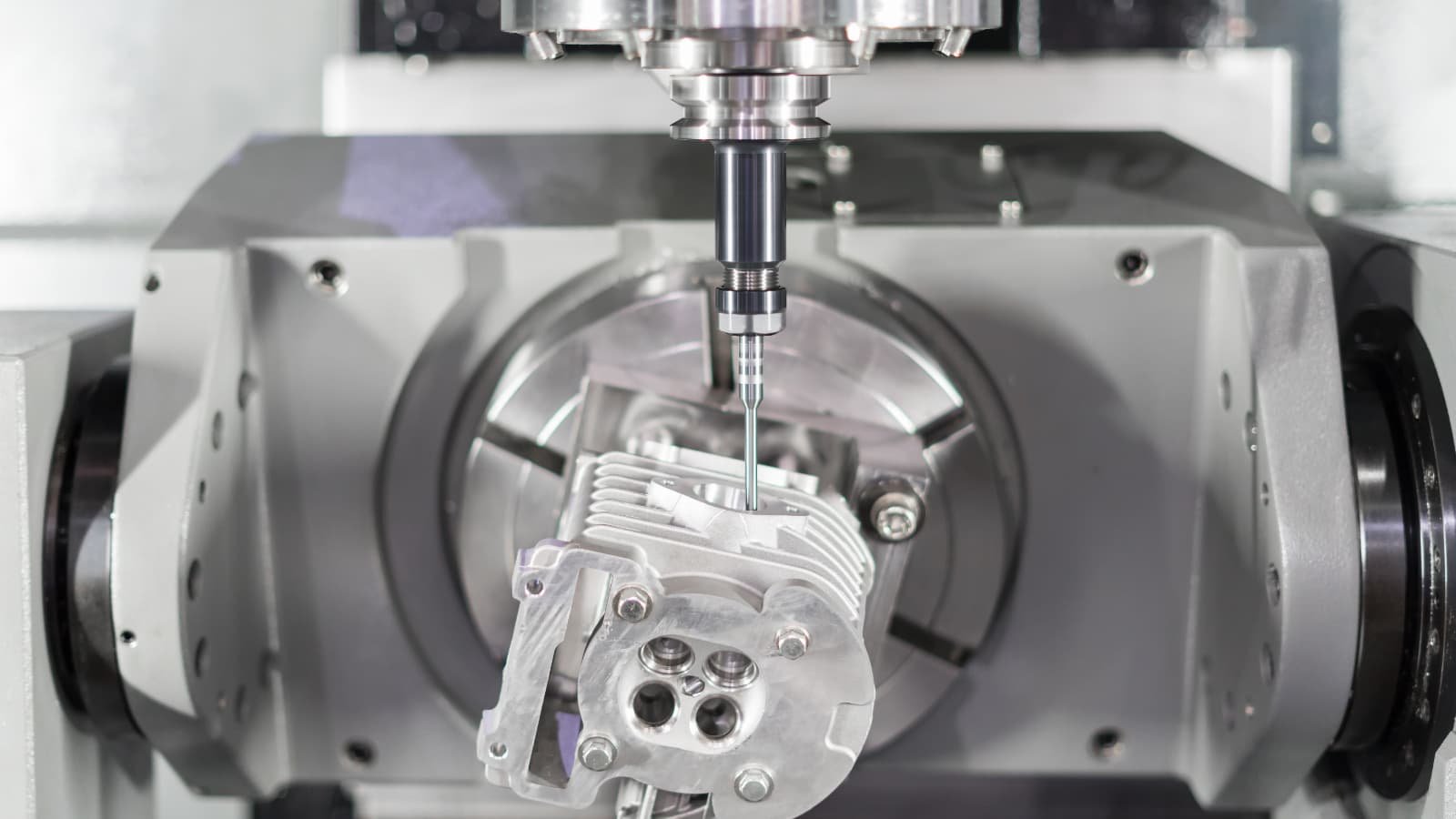

Expert evaluation ensures manufacturability and precision for every project blueprint involved in CNC machining.

Precise microscopic measurements guarantee each initial part meets stringent specifications.

Continuous sampling during production maintains consistent quality and detects deviations early.

Comprehensive final checks confirm flawless appearance and adherence to all quality standards.

Rapid prototyping with precision CNC machining ensures product accuracy and quick iteration. Our expert team supports every step for seamless development.

Scalable production capabilities maintain consistent quality and delivery timelines. Optimize costs while meeting growing demand with dependable volume strategies.

Extensive global shipping expertise ensures on-time delivery worldwide. We provide full visibility and customer service through every stage.

Optimize miniature bar materials for precision machining and durability. Enhance material adaptability to meet tight tolerance requirements efficiently.

Tailored surface treatments maintain integrity on small components. Improve corrosion resistance, wear protection, and finish quality.

Advanced cleaning and protective coatings extend part lifespan. Ensure optimal performance and maintain high-quality standards.

Partner with ZSCNC experts early to optimize designs for manufacturability. Our custom manufacturing process ensures high quality and efficiency.

We tailor processes to meet unique project specifications and timelines. Learn more about our custom company profile and capabilities.

Transparent updates and collaborative dialogue keep your project on track.