Custom aluminum CNC machined parts overview

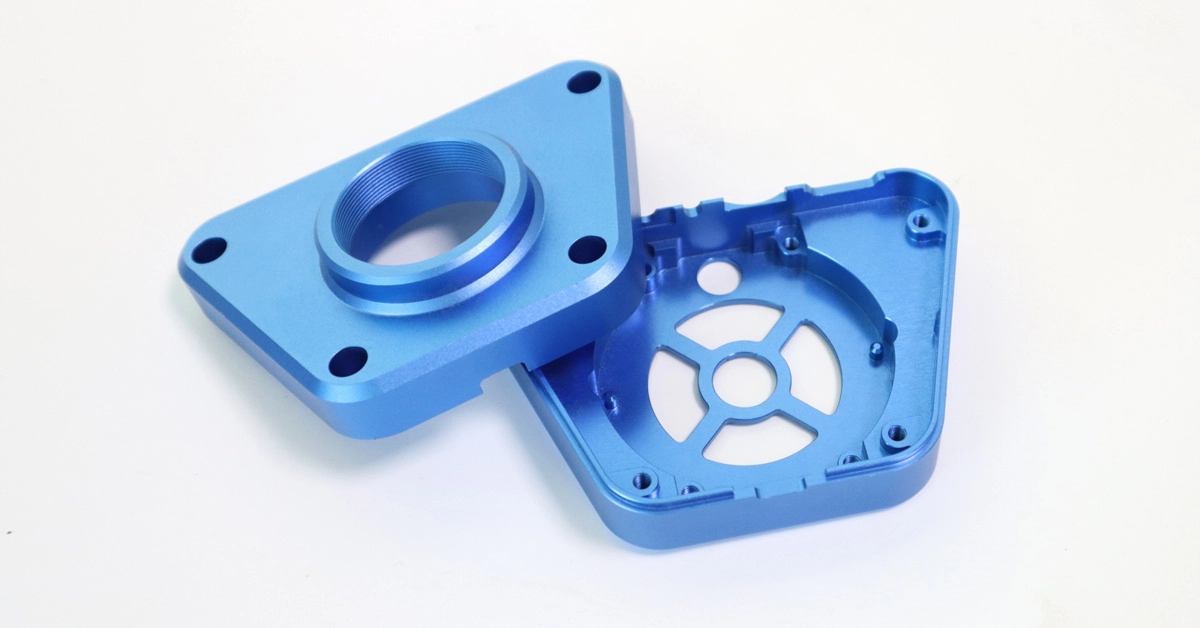

When you need aluminum parts that standard catalogs cannot provide, custom aluminum CNC machined parts are the answer. I use high‑precision CNC milling and turning to produce parts exactly to your drawing, with the right alloy, tolerances, and surface finish for your application.

What are custom aluminum CNC machined parts?

Custom aluminum CNC machined parts are:

- Non‑standard components produced from solid aluminum bar, plate, or billet

- Manufactured using CNC milling, CNC turning, and multi‑axis machining

- Defined by your 3D CAD model and 2D drawings, not by off‑the‑shelf dimensions

- Delivered with specified tolerances, threads, holes, and surface finishes (e.g. anodized aluminum CNC parts)

These can range from simple spacers and brackets to complex housings, heat sinks, and structural frames.

Who typically needs custom aluminum CNC machining?

My custom aluminum CNC machining service is used by:

- OEMs and product manufacturers needing proprietary parts and assemblies

- Aerospace, automotive, and motorsport teams requiring high‑strength lightweight aluminum parts

- Electronics, robotics, and automation companies needing CNC aluminum enclosures and housings

- Medical, lab, and industrial equipment builders who rely on tight tolerance aluminum CNC parts

- Startups and R&D teams that need rapid aluminum prototyping service and small batch runs

If your design is unique, safety‑critical, or branded, you likely need precision aluminum machining services, not catalog parts.

Key advantages of choosing aluminum for CNC parts

Aluminum alloys are often the best balance of performance, machinability, and cost:

- Lightweight but strong – Excellent strength‑to‑weight ratio, ideal for aerospace and automotive

- Easy to machine – Shorter cycle times, good chip control, and lower cost compared to many steels

- Good thermal and electrical properties – Perfect for CNC machined aluminum heat sinks and electronic housings

- Corrosion‑resistant with finishing – Type II and Type III anodized aluminum improves wear and corrosion resistance

- Clean, professional appearance – Ideal for visible OEM aluminum CNC parts and consumer products

Common alloys such as 6061 aluminum machined parts, 7075 aluminum machined components, 5052, and 2026 cover most structural, high‑strength, and forming needs.

Custom CNC machining vs off‑the‑shelf components

Off‑the‑shelf components are fine for basic builds, but they often limit your design. With my high precision CNC aluminum machining, you get:

-

Exact dimensions and features

- Custom hole patterns, pockets, threads, and cutouts

- Complex 3D surfaces and multi‑axis geometries

-

Application‑specific materials and finishes

- Choice of aluminum alloy and surface finished aluminum parts (anodizing, bead blasting, powder coating)

-

Controlled tolerances and quality

- From standard fits to tight tolerance aluminum CNC parts for critical assemblies

-

Branding and integration

- Custom CNC aluminum parts for robotics, aerospace, automotive, and OEM equipment designed to fit your system, not the other way around

If you need parts that fit perfectly, look right, and perform reliably, custom aluminum CNC machining delivers what off‑the‑shelf parts simply cannot.

Aluminum CNC Machining Capabilities

When you need custom aluminum CNC machined parts, we cover the full range from simple brackets to complex 5‑axis aerospace components.

CNC Milling for Aluminum (3‑Axis to 5‑Axis)

We run 3‑axis, 4‑axis, and 5‑axis CNC milling centers for:

- Precision CNC milled aluminum parts

- Complex pockets, contours, and thin walls

- Multi‑face machining in a single setup

Our 5‑axis CNC machining services handle tricky geometries, undercuts, and tight access areas with high precision, ideal for high precision CNC aluminum machining and CNC machined aerospace aluminum parts. You can see more about our 5‑axis capabilities on our dedicated 5‑axis CNC machining service page.

CNC Turning and Turn‑Milling

We provide aluminum CNC turning and milling for:

- Shafts, bushings, spacers, and pins

- Billet aluminum fittings and threaded connectors

- Turn‑milled parts with milled flats, slots, and cross holes in one setup

This is ideal for precision aluminum machining services where round features and prismatic details must be held in tight relationship.

Drilling, Tapping, and Threading

We routinely machine:

- Tapped holes, blind and through

- Metric/imperial internal and external threads

- Helicoil/insert-ready features and fine‑pitch threads

Our setups are optimized for clean, burr‑controlled anodized aluminum CNC parts, so threaded features stay sharp and functional after finishing.

Complex and Multi‑Operation Aluminum Machining

For more demanding parts, we combine:

- Multi‑axis milling + turning

- Secondary ops like EDM where needed, supported by our dedicated EDM machining services

- Custom fixtures for repeatable tight tolerance aluminum CNC parts

This lets us handle complex geometries, deep pockets, thin ribs, and intricate CNC aluminum enclosures and housings without sacrificing accuracy.

Size Range and Part Complexity

We support:

- Small precision components down to a few millimeters

- Medium to large OEM aluminum CNC parts and structural plates

- One‑off prototypes to full production runs

Typical envelope: small to mid‑sized billet aluminum machining and structural parts; if you have an extreme size or geometry, send us the CAD and we’ll validate it quickly.

Tight Tolerance Aluminum Machining (±0.005 mm)

For demanding industries like aerospace, robotics, and automotive, we offer:

- Tight tolerances down to ±0.005 mm on critical features

- Controlled flatness, parallelism, and position

- Full in‑process and final inspection with CMM and gauges

If you need high strength lightweight aluminum parts, 6061 aluminum machined parts, or 7075 aluminum machined components held to strict specs, we’re set up to run them with consistent, repeatable quality.

Custom Design and Engineering Support for Aluminum CNC Machined Parts

From CAD Model to Finished Aluminum Part

You send us your CAD data, we turn it into finished custom aluminum CNC machined parts—fast and repeatable.

Our process is simple:

- Upload files + RFQ – share 3D + 2D, quantities, material, and finish.

- DFM review – we run a manufacturability check and flag risks before cutting any billet aluminum.

- Quote + feedback – you get pricing, lead time, and design suggestions to improve cost and quality.

- CNC programming – we generate toolpaths for high precision CNC aluminum machining (milling, turning, and combined operations).

- Machining + finishing – we machine, deburr, and apply anodizing, coating, or other finishes as required.

- Inspection + shipping – parts are measured, packed, and shipped with full traceability if needed.

Supported CAD and Drawing File Formats

To keep things easy, our custom aluminum CNC machining service supports:

- 3D: STEP, IGES, Parasolid (X_T, X_B), STL

- 2D: PDF, DWG, DXF for dimensions, GD&T, and critical callouts

Send both 3D and 2D when possible—3D drives the machining, 2D locks in tolerances and surface finish.

DFM Tips for Aluminum CNC Machining

Good design cuts cost and lead time. For precision aluminum machining services, we suggest:

- Standardize hole sizes to match common drill diameters

- Avoid ultra‑tight tolerances unless absolutely necessary (tight tolerance aluminum CNC parts are possible, but more expensive)

- Keep features accessible for cutters; blind corners and deep pockets add time and setups

- Use our standard tolerance guidelines for 5‑axis parts as a baseline, then tighten only where function demands

Optimizing Wall Thickness, Radii, and Features

For 6061 aluminum machined parts, 7075 aluminum machined components, and other alloys, these rules work well:

- Wall thickness:

- General: ≥ 1.0–1.5 mm for small parts, thicker for large parts

- Thin walls add chatter and scrap; we’ll flag risky areas

- Internal radii:

- Use larger corner radii (e.g., 1–3 mm) to suit standard end mills

- Avoid “knife edges” and zero‑radius corners

- Pocket depth:

- Try to keep pockets ≤ 4–6× tool diameter for stable machining

- Threads:

- Use standard metric/imperial sizes

- For frequently assembled joints, consider steel inserts instead of direct aluminum threads

Collaborating With Our Engineers on Custom Aluminum Components

We don’t just take files and cut parts—we work with you like an in‑house CNC aluminum team. Our engineers support:

- Material selection (6061 vs 7075 vs 5052 vs 2026, etc.)

- Geometry tweaks to balance strength, weight, and cost

- Process planning: CNC milling, turning, and even complementary processes like wire EDM machining for ultra‑tight features

- Prototype‑to‑production transition, so your rapid aluminum prototyping service results can scale into stable, repeatable OEM aluminum CNC parts

Whether you’re refining CNC aluminum enclosures and housings, custom 6061 aluminum components, or lightweight brackets for robotics and automotive, we’ll help you get a design that runs cleanly on the machine and performs in the field.

Aluminum Alloys for CNC Machined Parts

When you’re buying custom aluminum CNC machined parts, the alloy you choose matters as much as the drawing. Different grades change strength, weight, corrosion resistance, and cost. Here’s how I usually guide global customers through the main options.

Common Aluminum Alloys for CNC Machining

Most CNC milled aluminum parts and turned components are made from a small group of proven alloys:

- 6061 aluminum

- 7075 aluminum

- 5052 aluminum

- 2026 aluminum

- 6082, MIC‑6, and other specialty grades

These cover almost all needs from lightweight brackets to high‑strength aerospace parts.

6061 Aluminum CNC Machined Parts

For most projects, 6061 aluminum CNC machined parts are the default:

- Use cases: general‑purpose, structural frames, mounts, CNC aluminum enclosures and housings, custom 6061 aluminum components.

- Pros: good strength‑to‑weight, easy to machine, great for precision aluminum machining services, takes Type II anodizing very well, stable and predictable.

- Why choose 6061: when you want a strong, cost‑effective, all‑round alloy for rapid aluminum prototyping and production.

7075 Aluminum CNC Machined Parts

If you need serious strength, we move to 7075 aluminum machined components:

- Use cases: aerospace fittings, motorsport parts, high‑load brackets, CNC machined aerospace aluminum parts.

- Pros: very high strength, close to some steels while staying lightweight.

- Cons: higher cost, a bit less corrosion‑resistant than 6061, more care needed in finishing.

- Why choose 7075: when performance and stiffness beat cost, especially in high strength lightweight aluminum parts.

5052 Aluminum CNC Parts

For formed or sheet‑based parts, CNC machining 5052 aluminum makes sense:

- Use cases: marine parts, panels, covers, bent enclosures, welded assemblies.

- Pros: great corrosion resistance (good for coastal or outdoor use), high formability, good for laser cutting + post‑machining.

- Why choose 5052: when your part is mainly sheet metal with some CNC features added.

2026 Aluminum CNC Components

For fatigue‑critical parts, we look at CNC machining 2026 aluminum:

- Use cases: aerospace components, structural brackets, load‑bearing parts that see repeated stress.

- Pros: strong and very fatigue‑resistant.

- Cons: weaker corrosion resistance, often needs protective coating.

- Why choose 2026: when your design faces repeated loads (vibration, cycling, impact) and long‑term durability is key.

Other Aluminum Alloys (6082, MIC‑6, Specialty Grades)

For more specific needs, we also run:

- 6082 aluminum: similar to 6061 but slightly better strength and often preferred in EU markets; good for OEM aluminum CNC parts and machinery structures.

- MIC‑6 cast aluminum: very flat and stable; ideal for billet aluminum machining service on plates, fixtures, machine bases.

- Other grades: tailored alloys for CNC machined aluminum heat sinks, high thermal conductivity, or special regulatory needs.

How to Choose the Right Aluminum Grade

I normally narrow the choice with a few direct questions:

- What matters most?

- Strength and stiffness → 7075 or 2026

- All‑round performance and cost → 6061 / 6082

- Corrosion + forming/welding → 5052

- Extreme flatness for plates and bases → MIC‑6

- Where will the part be used?

- Aerospace / motorsport → usually 7075 or 2026

- Robotics, automation, general OEM → mostly 6061 / 6082

- Marine, outdoor, humid → 5052 or anodized 6061

- What’s the budget and volume?

- Prototypes and small batch aluminum CNC machining → 6061 is usually smartest.

- Large volume aluminum CNC production → we balance unit cost, cycle time, and finishing.

If you share your use case, load conditions, and environment, I can recommend a specific aluminum alloy and finishing stack that hits performance, price, and lead time for your custom aluminum CNC machining service.

Surface Finishes for Custom Aluminum CNC Machined Parts

Why surface finishing matters for aluminum CNC parts

For custom aluminum CNC machined parts, finishing is not just about looks. It affects:

- Corrosion resistance – key for global customers in humid, coastal, or industrial environments

- Wear resistance – especially for tight tolerance aluminum CNC parts in motion or high-contact areas

- Brand image – clean, consistent finishes on CNC aluminum enclosures and housings matter on the shelf and in the field

- Function – better electrical insulation, heat dissipation, and easier cleaning, depending on the coating

I always recommend choosing the finish at the design stage so we can quote and build around it from day one.

Anodized aluminum CNC machined parts (Type II & Type III)

For most precision aluminum machining services, anodizing is the go-to:

-

Type II anodized aluminum CNC parts

- Good corrosion resistance

- Smooth, decorative finish

- Ideal for consumer products, custom 6061 aluminum components, electronics housings

-

Type III hard anodized aluminum

- Much thicker, harder coating

- High wear and abrasion resistance

- Popular for 7075 aluminum machined components, aerospace brackets, performance automotive parts

Both options work well with our high precision CNC aluminum machining and hold tolerances reliably when we account for coating thickness.

Color anodizing options

For branded or visible parts, we offer:

- Black, clear, natural, red, blue, gold, and custom colors (on request)

- Color-stable finishes for CNC machined aluminum prototypes and production runs

- Consistent appearance across small batch aluminum CNC machining and large volume aluminum CNC production

Color anodizing is ideal for custom aluminum brackets and housings, knobs, panels, and front plates where aesthetics and durability both matter.

Bead blasting & brushing

Before anodizing or left as-is, we use:

- Bead blasting – uniform matte finish, hides machining marks, great for CNC machined aluminum heat sinks, covers, and visible brackets

- Brushing – linear texture, “premium” look, common on CNC aluminum enclosures and housings and faceplates

Both options pair well with Type II anodized aluminum for a clean, modern look that still feels robust.

Powder coating for durable color

When customers want thicker, impact-resistant color, we offer:

- Powder coating in RAL and custom colors

- Good chip and scratch resistance for OEM aluminum CNC parts used in industrial and outdoor setups

- Works well on billet aluminum machined parts, frames, panels, and machine covers

We factor coating thickness into our aluminum CNC part design guidelines to keep critical fits within spec.

Chromate conversion coating (Alodine)

For components where conductivity or tight tolerances matter:

- Chromate conversion coating offers:

- Corrosion protection with minimal thickness

- Conductive surface, ideal for electronics and telecom aluminum parts

- Common on CNC machining 5052 aluminum and CNC machining 2026 aluminum in aerospace, telecom, and defense

This is a solid choice for grounding surfaces, EMI-sensitive housings, and machined sheet-based parts.

Polishing and plating options

For high-end, visible, or decorative surface finished aluminum parts, we support:

- Mechanical polishing for a bright or mirror look

- Nickel, chrome, or other plating on selected aluminum alloys (application-dependent)

These are often used on high strength lightweight aluminum parts in premium devices, medical equipment, and display hardware, where appearance is as important as function.

Every finish we offer is integrated into our custom aluminum CNC machining service workflow, so when you send a drawing or model, you get a quote that includes machining, finishing, and inspection from a single ISO-focused aluminum machining shop.

Performance, Tolerances, and Quality of Custom Aluminum CNC Machined Parts

Strength‑to‑Weight Performance

Custom aluminum CNC machined parts hit a sweet spot of high strength and low weight.

For global OEMs and startups, that means:

- Lighter assemblies with better energy efficiency (EVs, drones, robots, aerospace).

- High rigidity when using grades like 6061 and 7075 aluminum machined components.

- Better handling, faster response, and lower shipping and handling costs.

If you’re replacing steel, you often get 30–60% weight reduction with enough strength for real-world loads.

Thermal and Electrical Performance

Aluminum is a go‑to when you need heat and current to move quickly:

- CNC machined aluminum heat sinks for electronics and telecom.

- Enclosures and housings that work as both structure and passive cooling.

- Good electrical conductivity for grounding, shielding, and power components.

We machine profiles and fins that boost surface area, so your products run cooler and more stable under load.

Standard vs Tight‑Tolerance Aluminum CNC Parts

We offer both standard precision aluminum machining services and tight tolerance aluminum CNC parts:

- Standard tolerances (typical production):

±0.05–0.1 mm on most features. - Tight‑tolerance aluminum machining:

Up to ±0.005 mm on critical dimensions, depending on geometry, size, and alloy.

You decide where you need ultra-precision; we balance accuracy with cost so you don’t overpay for non‑critical areas.

How We Control Dimensions on CNC Aluminum Parts

To keep every batch consistent, we build quality into the machining process:

- FAI (First Article Inspection) before full run.

- In‑process checks by operators using gauges and micrometers.

- Controlled tool wear, tool offsets, and temperature‑aware setups on our high precision CNC aluminum machining centers.

- Stable fixturing for billet aluminum machining service and multi‑face operations.

This gives you repeatable results from rapid aluminum prototyping service to large volume aluminum CNC production.

Quality Inspection Tools and Methods

We verify your custom aluminum CNC machined parts using:

- CMM (Coordinate Measuring Machine) for complex 3D features and tight GD&T.

- Optical inspection systems for small features, slots, and contours.

- Pin gauges, ring gauges, height gauges, and surface roughness testers for everyday production checks.

For demanding sectors like CNC machined aerospace aluminum parts and aluminum machining for automotive parts, we treat every critical feature like it’s safety‑related.

Material Traceability and Test Reports

As an OEM aluminum CNC parts supplier, we keep full control over materials:

- Mill certificates and heat numbers recorded for each aluminum alloy batch (6061, 7075, 5052, 2026, etc.).

- Material traceability from raw stock to finished part, useful for audits and regulated industries.

- Optional test reports (chemical composition, mechanical properties, hardness) on request.

You know exactly what alloy went into which lot, which is key if you’re building medical systems, aerospace assemblies, or certified industrial equipment.

Industries Using Custom Aluminum CNC Machined Parts

Our custom aluminum CNC machined parts are built for real-world use, not just sample photos. Here’s where they’re working every day.

Aerospace Aluminum CNC Components

We supply CNC machined aerospace aluminum parts for global customers who need safety and reliability above everything else:

- Brackets, mounts, and fixtures in 6061 and 7075

- Lightweight housings and panels with tight tolerances

- High strength, low weight parts for airframes, UAVs, satellites, and ground support tools

We focus on high precision CNC aluminum machining and tight tolerance aluminum CNC parts that meet aerospace-level expectations.

Automotive and Motorsport Aluminum Parts

For automotive OEMs, race teams, and performance shops, we offer:

- Custom 6061 aluminum components for brackets, engine mounts, and intake parts

- 7075 aluminum machined components for high-stress suspension and drivetrain parts

- Billet aluminum machining service for custom blocks, steering components, and performance upgrades

We handle both small batch aluminum CNC machining for tuning shops and large volume aluminum CNC production for OEMs.

Electronics and Telecom Aluminum Enclosures

We’re a CNC milled aluminum parts manufacturer for global electronics and telecom brands that need clean, functional, and good-looking hardware:

- CNC aluminum enclosures and housings for routers, base stations, instruments

- CNC machined aluminum heat sinks for power electronics and LED systems

- Anodized aluminum CNC parts with Type II and Type III anodizing and color options

You get surface finished aluminum parts ready for assembly and branding.

Medical and Lab Aluminum Components

For medical device and lab equipment makers, we provide:

- Precision aluminum machining services for frames, panels, handles, and brackets

- Tight tolerance aluminum CNC parts for patient-facing and test equipment

- Smooth, consistent surfaces ready for anodizing, passivation, or coating

We support low-risk, repeatable production for regulated markets.

Robotics and Automation Aluminum Structures

We support global robotics startups, integrators, and factory automation teams with:

- CNC aluminum parts for robotics: arms, bases, sensor brackets, grippers

- Lightweight structural frames and plates in 6061, 6082, and 5052

- Custom aluminum brackets and housings for motors, gearboxes, and cameras

Our OEM aluminum CNC parts supplier model makes it easy to scale from prototype to full system rollout.

Industrial Machinery and OEM CNC Parts

For industrial equipment and OEM builders, we deliver:

- OEM aluminum CNC parts: plates, covers, guards, manifolds, spacers

- Billet and plate aluminum alloy CNC fabrication for machine frames and tooling

- Repeatable quality with ISO certified aluminum machining shop practices

We’re set up for rapid aluminum prototyping service, then smooth transition into ongoing production runs with stable quality and lead times.

Prototyping and Production Options for Custom Aluminum CNC Machined Parts

Rapid Aluminum Prototyping Service

For new product development, I keep rapid aluminum prototyping fast and practical:

- 1–50 pcs typical

- Ideal for design validation, fit tests, and investor samples

- Same alloys as production: 6061, 7075, 5052, 2026

- Full machining capability: CNC milling, CNC turning, multi‑axis

- Optional quick finishes: bead blast, clear anodized, basic dye colors

| Item | Typical Range |

|---|---|

| Qty (prototypes) | 1 – 50 pcs |

| Lead time | 3 – 10 working days |

| Tolerance (standard) | ±0.05 mm (tighter on request) |

| Process | CNC milling & turning in aluminum |

Low‑Volume CNC Runs (Pilot & Small Batch)

When you move past the first prototype, I support small batch aluminum CNC machining without forcing big MOQs:

- Perfect for pilot builds, pre‑production, and niche products

- 50–500 pcs typical, depending on part size and complexity

- Same fixtures, tooling, and programs we’ll use for production

- Consistent quality across brackets, housings, heat sinks, and OEM aluminum CNC parts

| Batch Type | Qty Range | Use Case |

|---|---|---|

| Pilot build | 20 – 100 pcs | Design validation, field test |

| Small batch | 50 – 500 pcs | Early customers, niche runs |

High‑Volume Aluminum CNC Production

When your product scales, I treat it as a production program, not a one‑off job:

- Hundreds to tens of thousands of CNC aluminum parts

- Optimized cycle times, multi‑fixture setups, tool libraries

- Stable supply for automotive, aerospace, robotics, telecom, and OEM customers

- Compatible with Type II / Type III anodized aluminum, powder coating, and custom packaging

| Volume Level | Typical Qty / Order |

|---|---|

| Mid volume | 500 – 5,000 pcs |

| Large volume | 5,000 – 50,000+ pcs |

| Supply mode | Batch or scheduled releases |

Lead Times: Prototypes vs Production

Lead times depend on complexity, quantity, and finishing, but this is a realistic guide:

| Stage | Typical Lead Time* |

|---|---|

| Rapid prototypes | 3 – 10 working days |

| Small batch / pilot runs | 1 – 3 weeks |

| Regular production | 3 – 6 weeks |

| Complex finishing (anodize, powder coat, plating) | +3–10 days |

*Actual timing varies by material, tolerance, and surface finish.

From One‑Off to Repeat Production

I design the whole process so you don’t have to re‑start every time:

- Same CNC programs used from prototype through mass production

- Early focus on aluminum CNC part design guidelines to avoid redesign later

- Process documentation: setup sheets, inspection plans, and material traceability

- Stable pricing and repeatability for ongoing orders

How I scale your custom aluminum CNC machined parts:

- Prototype: validate design and material (e.g., 6061 aluminum machined parts, 7075, 5052, 2026).

- Pilot batch: lock in tolerances, surface finish, and assembly fit.

- Production: optimize cycle time, fixtures, and tooling for large volume aluminum CNC production.

This way you get fast prototypes, reliable small batches, and repeatable high‑precision aluminum production from a single CNC partner.

Custom Features and Part Types for Aluminum CNC Machined Parts

I focus on custom aluminum CNC machined parts that actually fit how you build and ship products globally—no generic catalog parts, everything is made to print.

CNC Aluminum Enclosures and Housings

I build CNC aluminum enclosures and housings for electronics, telecom, EV, IoT, and industrial gear:

- One‑piece milled housings, split enclosures, and sealed boxes

- Options for heat dissipation, EMI shielding, and gasket grooves

- Clean internal pockets, connector cutouts, logos, and branding

- Ready for anodized aluminum CNC parts or powder coat

Billet Aluminum Machined Parts and Custom Blocks

For high strength

Cost Factors for Custom Aluminum CNC Machined Parts

When we quote custom aluminum CNC machined parts, we look at a few main cost drivers: material, tolerances/complexity, setup/programming, and finishing. Here’s how each one affects your price and what you can do to keep costs under control.

Material Choice and Aluminum CNC Part Pricing

Different aluminum alloys come with different material and machining costs:

- 6061 aluminum machined parts – Best price‑to‑performance for most jobs. Easy to machine, low waste, ideal for general custom 6061 aluminum components.

- 7075 aluminum machined components – Higher raw material price and tougher to cut. Great for high‑strength, aerospace or motorsport parts but expect a higher machining rate.

- 5052 and 2026 aluminum CNC parts – Priced between 6061 and 7075 depending on spec, form (plate, billet, extrusion), and availability.

- Special alloys (6082, MIC‑6, etc.) – Cast and specialty grades for high stability or flatness cost more, but can reduce machining time in precision aluminum machining services.

If you’re flexible, I’ll usually recommend 6061 first. It gives you a strong, lightweight part at the lowest overall CNC aluminum fabrication cost.

Tolerances, Part Complexity, and Machining Time

Two things drive machining cost harder than anything else: how tight and how complicated.

- Tight tolerance aluminum CNC parts (e.g. ±0.005 mm / ±0.0002 in) need:

- Slower feeds

- More toolpaths and passes

- Extra inspection time (CMM, gauges)

- Complex geometry (deep pockets, thin walls, undercuts, multi‑axis) means:

- Longer cycle times on 4‑axis / 5‑axis machines

- Custom fixturing and more setups

- Higher scrap risk on small‑wall CNC milled aluminum parts

If you only need tight tolerances on critical features, and we can open up the rest, your price drops fast without hurting function.

Setup, Programming, and Tooling

Every new custom aluminum CNC machining job has a fixed cost we need to spread over the order:

- CAM programming for multi‑axis operations, turn‑milling, and complex billet aluminum machining service

- Setup time for fixtures, workholding, and dial‑in

- Special tooling (micro end mills, form tools, deep‑hole drills, thread mills)

For small batch aluminum CNC machining, setup can be a big part of the unit price. For large volume aluminum CNC production, that cost gets diluted over many parts, so unit price drops sharply.

Finishing, Anodizing, and Secondary Operations

Surface finishing can easily add 20–40% to part cost depending on the spec:

- Type II anodized aluminum CNC parts – Standard for cosmetics and basic corrosion resistance; cost depends on color, thickness, and batch size.

- Type III hard anodizing – More expensive, used for wear and heavy‑duty CNC machined aerospace aluminum parts and automotive components.

- Bead blasting, brushing – Adds labor and handling but gives clean, uniform matte surfaces before anodizing or powder coating.

- Powder coating, chromate conversion, polishing, plating – Each extra step adds handling, lead time, and QC.

I always quote machining + finishing together so you see the true landed cost per part from one OEM aluminum CNC parts supplier.

How to Reduce Cost on Custom Aluminum CNC Designs

You can usually cut cost without sacrificing performance by adjusting a few details:

- Choose 6061 when possible

Stick to 6061 for most structural CNC aluminum enclosures and housings, brackets, plates, and frames unless you truly need 7075 or 2026. - Relax tolerances where you can

- Use standard ISO / DIN fits on non‑critical surfaces

- Keep tight tolerance zones small and local

- Simplify geometry

- Avoid unnecessary undercuts and deep, narrow pockets

- Thicken ultra‑thin walls if possible

- Limit the need for 5‑axis if 3‑axis or simple aluminum CNC turning and milling will do

- Standardize features

- Use standard thread sizes and depths

- Reuse hole sizes and patterns across parts

- Batch your orders

- Combine prototypes or versions into one run

- Plan for repeat production to spread programming and setup cost

If you share your CAD and priorities (cost vs. weight vs. strength vs. look), I can give you straight, practical aluminum CNC part design guidelines to hit your budget and performance targets.

Ordering And Quote Process For Custom Aluminum CNC Machined Parts

What You Need For A CNC Aluminum Quote

To quote custom aluminum CNC machined parts fast and accurately, I usually ask for:

- 3D model: STEP, STP, IGES, X_T (preferred for CNC milled aluminum parts)

- 2D drawing (if available): PDF, DWG, DXF with key dimensions, tolerances, and surface finish notes

- Material: 6061, 7075, 5052, 2026, 6082, MIC‑6, or other specified aluminum alloy

- Quantity: prototypes, small batch aluminum CNC machining, or large volume aluminum CNC production

- Finish: anodized aluminum CNC parts (Type II / Type III), bead blasting, powder coating, etc.

- Special requirements: tight tolerance aluminum CNC parts, CMM reports, material certs, or ISO‑level documentation

The more complete your info, the more accurate and competitive the quote for your precision aluminum machining services.

Uploading Drawings And 3D Models

I keep file upload simple for global customers:

- Online upload through our quote form (drag‑and‑drop STEP + PDF)

- Secure transfer links (for NDA and OEM aluminum CNC parts supplier projects)

- Support for all common CAD formats used for CNC aluminum enclosures and housings, brackets, heat sinks, and billet aluminum machined parts.

If your files aren’t “clean,” I can still work with them and help finalize.

Typical Quote Turnaround Time

For most custom aluminum CNC machining service requests:

- Standard RFQs: 24–48 hours

- Complex multi‑axis aluminum machining or tight‑tolerance builds: 2–3 working days

- Urgent rapid aluminum prototyping service: same‑day ballpark pricing on request

I’ll always tell you upfront if extra time is needed.

From Quote Approval To Production And Shipping

Once you approve the quote for your CNC machined aluminum parts, the flow is:

- DFM check & confirmation – we lock material, tolerances, finish, and lead time.

- Programming & CAM – toolpaths for CNC milling, aluminum CNC turning and milling, and any secondary ops.

- Machining – rough, semi‑finish, and finish cuts for high precision CNC aluminum machining.

- Finishing – anodizing, bead blasting, brushing, powder coating, or chromate conversion as requested.

- Inspection – CMM, gauges, and visual checks according to your drawing and spec.

- Packing & shipping – export‑ready packaging for global delivery, with full traceability if needed.

You get updates at each critical step, so you always know where your order stands.

Revisions, Repeat Orders, And Engineering Changes

I design the process so you can iterate fast:

- Revisions / ECOs: send updated STEP/PDF with revision notes; I’ll highlight what changes cost and lead time.

- Repeat orders: we reuse proven CNC programs, fixtures, and process sheets to keep quality stable and price optimized.

- Version control: each design revision of your custom 6061 aluminum components, 7075 aluminum machined components, or CNC machined aerospace aluminum parts is tracked and labeled.

This way, whether you’re ordering one prototype or ongoing OEM aluminum CNC parts, you get consistent results without surprises.

Common Questions About Custom Aluminum CNC Machined Parts

Typical Lead Times for Aluminum CNC Machining

For custom aluminum CNC machined parts, I usually quote:

- Rapid prototypes: 3–7 working days (depending on complexity and finishing)

- Small batch runs: 7–15 working days

- Large volume production: 3–6 weeks, once the process is stabilized

Lead time depends mainly on part complexity, tight tolerances, and finishing like anodizing or powder coating.

Minimum Order Quantities (MOQ)

My custom aluminum CNC machining service is flexible:

- Prototypes: MOQ = 1 piece (ideal for testing and design validation)

- Small batch / pilot runs: 10–100+ pieces

- OEM production: Scalable to thousands of parts with stable pricing

You can start with rapid aluminum prototyping and move into small batch aluminum CNC machining or large volume aluminum production without switching suppliers.

Supported CAD Formats and Drawing Standards

For precision aluminum machining services, I accept:

- 3D models: STEP, STP, IGES, IGS, Parasolid (X_T, X_B), STL

- 2D drawings: PDF, DWG, DXF

I follow common GD&T practices and international drawing standards (ISO/ASME). Clear tolerances, threads, and surface finish notes help me quote accurately.

Maximum Part Size and Minimum Feature Size

My CNC milled aluminum parts manufacturing setup handles:

- Max part size: up to ~1000 mm length (depending on geometry and fixture method)

- Minimum feature size: down to 0.5–1.0 mm tools for small slots, holes, and pockets

- Tight tolerance aluminum CNC parts: as tight as ±0.005 mm on critical features (upon request)

For very thin walls or micro-features, I review the aluminum alloy, part stiffness, and machining strategy with you first.

Choosing Aluminum vs. Other Metals for CNC Machining

Here’s how I usually guide customers globally when picking materials:

Choose aluminum CNC machining when you need:

- High strength‑to‑weight (great for aerospace, robotics, automotive brackets and housings)

- Good thermal performance (CNC machined aluminum heat sinks, enclosures, base plates)

- Fast, cost‑effective machining (shorter cycle times vs. stainless or titanium)

- Surface finished aluminum parts with anodizing, powder coating, or chromate conversion

Consider other metals when you need:

- Very high wear or temperature resistance: stainless steel, tool steel

- Extremely high strength at elevated temps: titanium, Inconel (for harsh aerospace/energy)

- Special magnetic or stainless properties: carbon steel or specific stainless grades

If you’re unsure whether 6061 aluminum machined parts, 7075 aluminum machined components, or another alloy (5052, 2026, 6082, etc.) fits your project, I usually look at:

- Load and stress levels

- Environment (outdoor, marine, medical, cleanroom)

- Required tolerances and surface finish

- Target cost per part and volume

Share your drawings, use case, and priorities, and I’ll recommend a cost‑effective, high precision CNC aluminum machining solution that matches your market and performance needs.

Reviews

There are no reviews yet.