What is CNC Mill-Turn Machining?

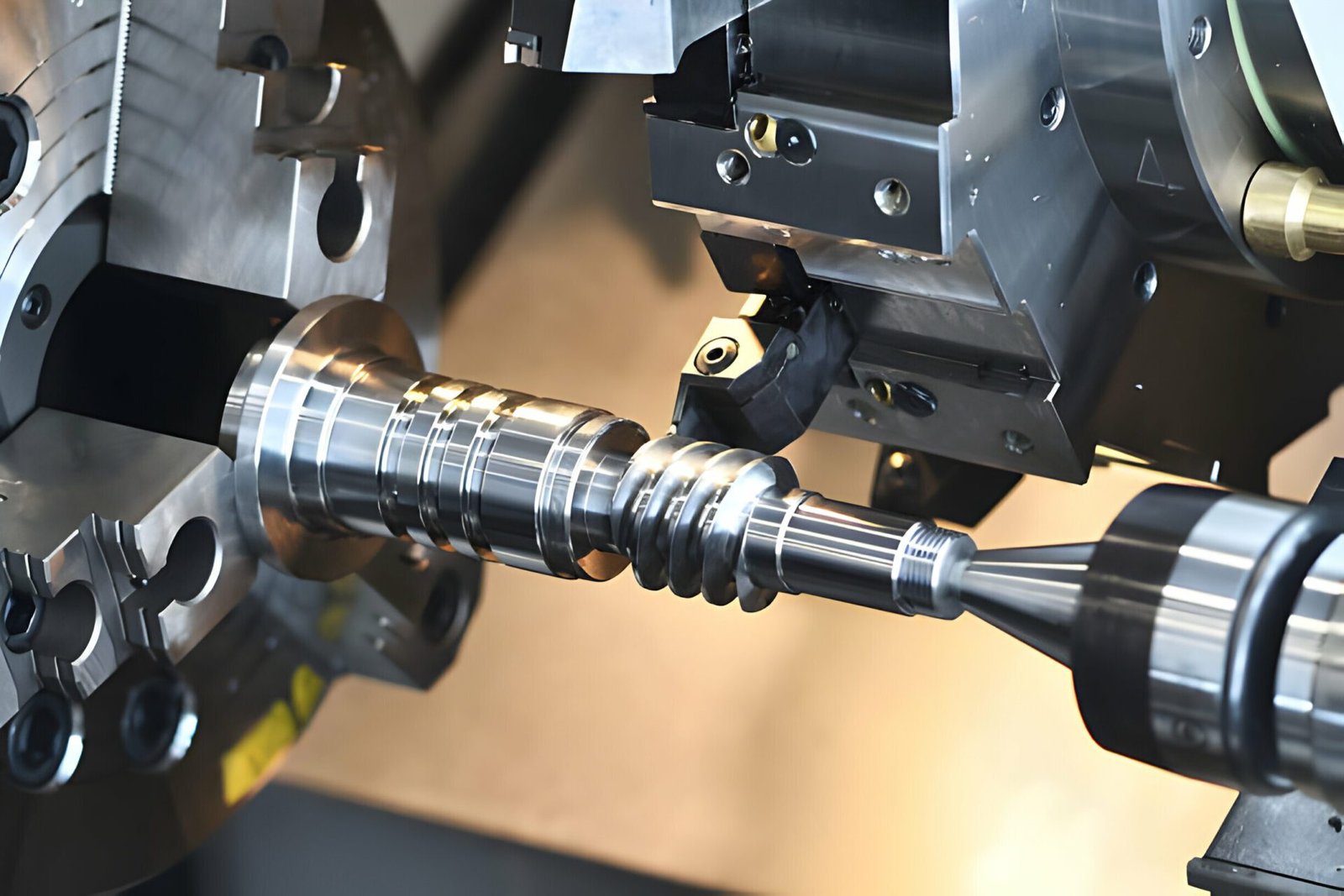

At ZSCNC, we define CNC mill turn machining as the ultimate convergence of lathe precision and milling versatility. Instead of treating these as separate workflows, our advanced turn-mill centers combine them into a single, seamless operation. This isn’t just about cutting metal; it’s about utilizing multi-tasking CNC services to produce complex cylindrical parts with geometries that standard turning simply cannot achieve.

Integration of Live-Tool Turning and Milling

The core of this technology lies in live tooling CNC machining. In a traditional setup, the cutting tool remains stationary while the part spins. In our mill-turn machines, the turret is equipped with rotating power tools—drills, taps, and end mills—that perform milling operations while the workpiece is still clamped in the spindle.

- Y-Axis Capabilities: Allows for off-center milling, drilling, and flat surface machining.

- C-Axis Indexing: Provides precise rotational positioning for complex contouring and slots.

- Sub-Spindle Handoff: Enables machining on the back side of the part without manual intervention.

Done-in-One Machining Explained

We focus on a done-in-one CNC parts philosophy. This means raw bar stock enters the machine, and a fully finished component exits. By leveraging CNC turning and milling combined, we eliminate the bottleneck of moving parts between multiple machines. This one-setup machining approach ensures that reference points remain consistent throughout the entire process, drastically reducing stack-up errors and handling damage.

Comparing Mill-Turn vs. Traditional Methods

To understand why multi-axis mill-turn services are superior for complex parts, compare the workflows below:

| Feature | Traditional Machining (Separate Ops) | CNC Mill-Turn (Integrated) |

|---|---|---|

| Setups Required | Multiple (Lathe + Mill + Fixturing) | One-setup machining |

| Handling Risk | High (Manual transfer errors) | Zero (Automated transfer) |

| Cycle Time | Long (Queue times between machines) | Fast (Simultaneous operations) |

| Precision | Variable (Re-fixturing loss) | High (Superior concentricity) |

By adopting high-precision mill-turn strategies, we transform how complex components are manufactured, offering you a streamlined path from design to finished product.

Key Advantages of Our Mill-Turn Services

When you choose our CNC Mill-Turn Services, you aren’t just getting parts; you are unlocking a streamlined manufacturing solution. By combining turning and milling into a single operation, we solve the biggest headaches associated with traditional multi-machine processes. We focus on delivering precision mill-turn components that meet the rigorous demands of the global market.

Here is why switching to one-setup machining makes sense for your project:

- Superior Concentricity and Precision: Because the workpiece remains in the chuck for the entire process, we achieve tight tolerances that are nearly impossible to match when moving parts between machines. This guarantees superior alignment and accuracy.

- Reduced Setup Times and Handling Errors: Every time a machinist moves a part from a lathe to a mill, there is a risk of fixture error. Our done-in-one CNC parts approach eliminates these manual transfers, significantly lowering the chance of defects and ensuring consistency.

- Faster Turnaround: Efficiency translates directly to speed. By consolidating operations, we drastically cut down idle time. This allows us to offer accelerated rapid prototyping services and quicker delivery for full-scale production runs.

- Cost Effectiveness for Complex Geometries: For complex cylindrical parts machining, paying for multiple setups adds up fast. Our integrated approach reduces machine time and labor costs, making intricate designs much more affordable without sacrificing quality.

Machine Capabilities and Specifications

At ZSCNC, we utilize advanced turn-mill centers designed to handle complex geometries that standard lathes simply cannot touch. Our multi-axis mill-turn services range from 4-axis setups to sophisticated 9-axis configurations, enabling us to approach a workpiece from virtually any angle. This versatility is essential for producing high-precision mill-turn components without multiple setups.

We integrate live tooling CNC machining with twin spindle features (sub-spindle), allowing us to transfer parts automatically from the main spindle to the secondary spindle. This means we can machine the back end of a part while the front end is being finished, significantly reducing cycle times. For engineers looking to maximize this technology, understanding design tips for parts that will be machined on 5-axis CNC helps in creating models optimized for our multi-tasking equipment.

Key Technical Specifications

Our facility is equipped to handle both small, intricate electronics and larger industrial components. Here is a breakdown of our machine capabilities:

| Feature | Specification |

|---|---|

| Axis Configuration | Up to 9-Axis (including Y-axis and B-axis milling) |

| Machining Precision | Tight tolerances down to ±0.005 mm |

| Spindle Setup | Dual Spindle (Main + Sub-spindle) for done-in-one processing |

| Max Swing Diameter | Capable of handling large diameter turning (up to 600mm) |

| Supported Operations | Drilling, Rigid Tapping, Contouring, Off-center Milling, Hobbing |

By combining turning and milling into a single workflow, we ensure superior concentricity and surface finish for every project.

Material Options for Mill-Turn Parts

We provide access to over 120 metals and plastics, ensuring your complex cylindrical parts meet exact mechanical and chemical requirements. Our extensive supply chain allows us to source everything from standard aluminum to superalloys, suitable for industries ranging from medical to aerospace. Whether you need a single prototype or a batch of 10,000 units, we match your project with the right material capabilities.

Metals and Alloys

Our network routinely processes standard alloys and hard metals. We offer precision machining of stainless steel grades including 304, 316L, and 17-4PH for corrosion-resistant applications. For projects demanding high strength-to-weight ratios, we supply Titanium (Grade 5), Magnesium, and Steel Alloys like 4140. We also handle soft metals such as Brass and Copper for electrical and decorative components.

Engineering Plastics

For non-metallic requirements, we utilize CNC mill turn machining for high-performance polymers. This includes machining PEEK for medical devices, as well as Nylon (PA6/6), POM (Acetal), ABS, and Polycarbonate for durable industrial parts.

Common Material Specifications:

| Material Family | Popular Grades | Key Characteristics |

|---|---|---|

| Aluminum | 6061, 7075 | Excellent machinability, high strength-to-weight ratio |

| Stainless Steel | 303, 304, 316L | High corrosion resistance, ideal for medical/marine use |

| Hard Metals | Titanium Gr 5, Inconel | Superior heat resistance and durability |

| Plastics | PEEK, Delrin, Nylon | Low friction, electrical insulation, chemical resistance |

| Soft Metals | Brass, Copper | High electrical conductivity, aesthetic finish |

Industries Benefiting from Multi-Axis Mill-Turn Services

Our multi-axis mill-turn services are the go-to solution for industries requiring complex geometries and strict concentricity. By combining turning and milling into a single setup, we deliver precision mill-turn components faster and more accurately than traditional multi-machine processes. This “done-in-one” approach is critical for sectors where part failure is not an option.

We specialize in complex cylindrical parts machining for the following high-demand fields:

- Aerospace & Defense: We manufacture critical components like fuel system parts, landing gear actuators, and sensor housings. These parts demand absolute reliability and tight tolerances, often machined from difficult materials like Titanium and Inconel.

- Medical Devices: The medical sector relies on us for intricate surgical instruments, bone screws, and implants. Our capabilities meet the strict key requirements for CNC machining medical device components, ensuring high precision and excellent surface finishes for biocompatibility.

- Automotive & Performance: From turbocharger housings to transmission shafts, we produce high-performance custom CNC machined automotive parts that can handle extreme stress and heat.

- Oil & Gas: We machine durable valves, fittings, and downhole tools capable of withstanding high pressure and corrosive environments.

- Robotics & Electronics: Our CNC mill turn machining is ideal for creating small, complex connectors, robotic joints, and electronic housings that require integrated operations to maintain alignment.

Surface Finishes and Post-Processing

A precision mill-turn component isn’t complete until it meets your exact surface requirements. We offer a gallery of over 30 surface finishes to ensure your parts not only meet tight tolerances but also achieve the necessary aesthetic and mechanical properties. Whether you need a standard “as-machined” look or a specialized coating for harsh environments, our post-processing capabilities cover every angle.

Our finishing options for CNC mill turn machining include:

- Anodising & Passivation: Crucial for corrosion resistance and wear protection. We provide Clear, Black, and Hard Anodising (Type II and III) for aluminium, alongside chemical passivation for stainless steel to prevent rust.

- Bead Blasting: To remove tool marks from CNC turning operations and milling cuts, we use bead blasting (ranging from 30 to 220 grit). This creates a uniform, matte texture that hides minor imperfections.

- Powder Coating & Polishing: For parts requiring high durability or a mirror-like aesthetic, we offer robust powder coating in various colors and manual polishing services.

- Heat Treatment: We improve the mechanical properties of your metal parts, such as hardness and strength, through precise thermal cycling.

From cosmetic upgrades to functional hardening, our post-processing ensures your complex cylindrical parts are ready for immediate assembly or end-use.

Our Manufacturing Process

We have digitized the traditional supply chain to make ordering complex mill-turn parts as easy as printing a sheet of paper. Our streamlined manufacturing process connects you with a global network of vetted partners, ensuring rapid turnaround and consistent quality.

Step 1: CAD File Upload

Start by uploading your 3D designs directly to our secure platform. We support a wide range of industry-standard formats, including .STEP, .STL, .IGS, .PDF, .DXF, and .DWG. This flexibility ensures we can interpret your exact specifications immediately.

Step 2: DfM Feedback & Instant Quote

Our AI-driven system analyzes your geometry instantly. For complex mill-turn projects, you receive a detailed quote within 24 hours. We provide the “best of at least 3 quotes,” allowing you to choose the optimal balance between cost and speed. Additionally, qualified engineers provide free Design for Manufacturing (DfM) feedback to highlight potential production issues before machining begins.

Step 3: Precision Production

Once the order is confirmed via card or company credit, production starts across our network of over 4,000 CNC machines. We handle everything from one-off prototypes to high-volume batches of 10,000+ units, utilizing 3-axis, 5-axis, and specialized mill-turn centers to meet your specific tolerances.

Step 4: Quality Inspection & Shipping

Quality is non-negotiable. All parts undergo rigorous virtual and physical quality control checks, strictly adhering to ISO 9001:2015 and ISO 13485 standards. After passing inspection, your components are securely packaged and shipped globally, with lead times as fast as 3–5 days.

Why Partner With ZSCNC?

Choosing the right manufacturing partner is about reliability, speed, and access to the best technology. At ZSCNC, we provide a streamlined gateway to over 1,100 global manufacturing partners, giving you access to more than 4,000 CNC machines through a single point of contact. Whether you need complex CNC mill-turn services or standard machined components, we simplify the entire supply chain.

Certified Quality and Compliance

We operate with strict adherence to global standards. Our network holds ISO9001:2015 and ISO13485 (medical) accreditations, ensuring every part meets rigorous specifications. We thoroughly vet our 350+ core partners, and every order undergoes both virtual and physical QC checks before it leaves the facility.

In-House Engineering Support

We don’t just manufacture; we optimize. Our qualified engineers provide free Design for Manufacturing (DFM) feedback to ensure your designs are production-ready. This support is crucial for avoiding the top mistakes engineers make when ordering custom CNC parts, helping you save time and reduce material waste.

Scalability and On-Time Delivery

- Rapid Turnaround: We offer lead times as fast as 3–5 days for urgent projects.

- Flexible Volume: Our facilities scale effortlessly from single prototypes to full production batches of 10,000+ units.

- Cost Efficiency: Our system compares quotes to find the best option, ensuring we are rarely beaten on price while maintaining high precision.

Frequently Asked Questions (FAQ)

What is the difference between CNC turning and mill-turn?

Traditional CNC turning rotates the workpiece while a stationary tool cuts it, which is great for simple cylindrical shapes. CNC mill turn machining combines this with rotating tools (live tooling) that can mill features like slots, holes, and flats while the part is still in the lathe. This “done-in-one” approach allows us to manufacture complex cylindrical parts in a single setup, significantly improving concentricity and reducing production time compared to moving parts between separate machines.

What file formats do you accept?

To get an instant quote or a detailed engineering review, we recommend uploading 3D CAD files. We support a wide range of formats to ensure compatibility with our system:

- .STEP and .IGS (Preferred for 3D data)

- .STL (Common for prototyping)

- .DXF and .DWG (For 2D drawings and tolerance specifications)

- .PDF (For technical drawings and finish requirements)

How fast can you deliver mill-turn parts?

Speed is a core part of our service. By leveraging our extensive network of manufacturing partners, we can offer lead times as fast as 3–5 days for urgent orders. For standard production runs, we optimize the schedule to balance cost and speed, ensuring you receive your parts exactly when you need them.

Do you handle both prototypes and mass production?

Yes, our platform is built for scalability. We handle everything from one-off prototypes for design validation to full-scale production runs exceeding 10,000 units. Whether you need a single complex component to test a concept or high-volume manufacturing for market release, our capacity adjusts to your project requirements.

What are your standard tolerances?

We adhere to strict quality standards to ensure every part fits your assembly perfectly. Our standard manufacturing tolerance is +/- 0.127mm, which is suitable for most commercial applications. For high-precision requirements, such as aerospace or medical components, we can achieve much tighter specifications. We regularly handle projects requiring industrial-grade CNC machining accuracy down to +/- 0.005mm and even +/- 0.001mm for critical features.

Reviews

There are no reviews yet.