Aluminum for Aerospace CNC Parts

When you buy aluminum for aerospace CNC parts, you’re usually balancing three things: strength-to-weight, precision, and compliance. My shop is set up specifically for that mix. We machine aerospace aluminum alloys (7075, 6061, 2026, 7050, and more) into precision aerospace components that stay light, accurate, and certifiable.

Core Needs of Aerospace Buyers

For CNC machined aircraft parts, most engineers and buyers ask for:

- High strength-to-weight

- Use of aviation grade aluminum like 7075 aluminum aerospace and 7050 aerospace aluminum for structurals and high-load parts

- Lightweight designs: thin wall aluminum machining, deep pockets, and optimized ribs

- Tight and repeatable tolerances

- Stable aerospace tolerances machining for complex 5 axis CNC aerospace machining

- Clean, burr-free CNC milling aluminum aircraft parts and CNC turning aerospace aluminum

- Compliance and documentation

- Support for AMS compliant aluminum parts and MIL spec aluminum machining

- Full material traceability, process control, and inspection records

You get high-strength aluminum CNC parts that are designed to pass audits, not just fit on the aircraft.

Where Aluminum CNC Parts Fit in Aircraft Systems

We supply aerospace-grade aluminum machining services across multiple aircraft systems, including:

- Aircraft structural parts and brackets

- Aircraft bracket CNC machining, frames, supports, and mounts

- Lightweight aircraft structural parts for primary and secondary structures

- Fluid and mechanical systems

- Aerospace hydraulic manifold machining, fuel manifolds, blocks, and 2026 aluminum fittings

- Actuation housings and linkages where stiffness and fatigue resistance matter

- Avionics, interiors, and enclosures

- Aluminum aerospace housings and enclosures for electronics and avionics

- Light, rigid interior structures that benefit from anodized aluminum parts

If you need custom aluminum prototypes aerospace through to production-ready precision aerospace components, we use the right aerospace aluminum alloys and CNC processes to match your load cases, environment, and certification path.

Why aluminum for aerospace CNC machining

Aluminum is still the go‑to material for many CNC machined aircraft parts because it hits the sweet spot between performance, machinability, and cost.

Strength-to-weight ratio benefits

Aerospace aluminum alloys like 7075, 6061, 2026, and 7050 offer:

- High strength at very low weight, ideal for aircraft structural parts and brackets

- Excellent performance in thin-wall aluminum machining, pockets, and lightweight frameworks

- Consistent, predictable behavior for precision aerospace components and 5 axis CNC aerospace machining

You get strong, rigid parts without paying the weight penalty of steel or titanium where they’re not needed.

Corrosion and fatigue performance in flight

In real flight conditions, aluminum for aerospace CNC parts handles:

- Corrosion resistance with the right alloy + coating (anodizing, chromate conversion)

- Good fatigue life for parts that see repeated loading, such as 2026 aluminum fittings and aircraft brackets

- Stable performance in humidity, salt, and hydraulic fluids, especially when we combine good design with proper surface treatment

For many non-engine hot zone parts, high‑strength aluminum is more than enough vs exotic alloys.

Thermal stability and dimensional accuracy

Aviation grade aluminum offers:

- Low thermal expansion compared to plastics or composites, which matters for avionics housings and enclosures

- Stable dimensional accuracy under temperature swings from ground to altitude

- Clean, predictable cutting behavior in CNC milling aluminum aircraft parts, which helps us hold tight aerospace tolerances

With modern 3-, 4-, and 5-axis CNC machining services and closed-loop temperature control, we keep parts within spec even on complex geometry. (You can see how we handle this on our 5-axis CNC machining page.)

Cost and lead time advantages vs other alloys

Compared with titanium, nickel alloys, or stainless steel, aerospace aluminum alloys give you:

- Faster machining: shorter cycle times, less tool wear, easier chip control

- Lower material cost: especially important for larger aircraft structural parts

- Shorter lead times: ideal for custom aluminum prototypes for aerospace and urgent spares

- Easier scalability from prototype to production with stable, repeatable machining programs

In short: if you want high-strength aluminum CNC parts that are light, accurate, and AMS/MIL-spec ready—while keeping cost and lead time under control—aluminum is usually the smartest starting point.

Best aluminum alloys for aerospace CNC parts

Picking the right aluminum for aerospace CNC parts is all about balancing strength, weight, fatigue life, and machinability. Here’s how I usually match alloys to real aircraft needs.

7075-T6/T651 – For high-stress structural parts

7075-T6/T651 is a go-to “workhorse” when you need very high strength and low weight.

- Ideal for: aircraft brackets, wing and fuselage fittings, landing gear lugs, and high-load joints

- Pros: Outstanding strength‑to‑weight, good machinability, strong fatigue performance

- Watch out for: Lower corrosion resistance than 6XXX series – usually paired with hard anodizing or conversion coating

6061-T6/T651 – For general aerospace components

6061-T6/T651 is the most versatile alloy for CNC machined aircraft parts.

- Ideal for: avionics housings, interior structures, mounts, panels, non‑critical structural parts

- Pros: Great balance of strength, corrosion resistance, and cost, very machinable, weldable

- Best when you need stable, repeatable machining and solid performance without the cost of premium high‑strength grades

2026-T3/T351 – For fatigue‑critical applications

2026-T3/T351 is chosen when fatigue resistance matters more than anything.

- Ideal for: fittings, ribs, clips, tension members, and other fatigue‑critical aircraft structural parts

- Pros: Excellent fatigue strength and good damage tolerance

- Needs protection: Not very corrosion‑resistant, so we nearly always spec anodizing or primer in aerospace environments

7050-T7451 – For thick, highly loaded sections

7050-T7451 is engineered for thick, highly loaded aerospace structures.

- Ideal for: bulkheads, landing gear components, heavy frames, and thick machined blocks

- Pros: High strength through thick sections, good stress‑corrosion and exfoliation resistance

- Typically supplied in plate for deep-pocket, 5‑axis CNC machining of structural parts

How to choose the right aerospace aluminum grade

When I help customers choose an aerospace aluminum alloy, we usually run through this checklist:

- Load & safety level

- High‑stress + structural? → 7075 or 7050

- General structural + housings? → 6061

- Fatigue‑driven design? → 2026

- Environment & corrosion

- Harsh / marine / de‑icing chemicals → Favor 6061 or 7050 with the right coating

- Internal, protected areas → 7075 or 2026 with proper surface treatment

- Geometry & machining requirements

- Thin walls, deep pockets, complex 5‑axis shapes → All four are workable, but 6061 often gives the best mix of stability and cost

- Very thick sections → 7050-T7451 is usually the safer choice

- Cost & volume

- Cost‑sensitive, high volume → 6061-T6/T651

- Performance‑driven, certified structural parts → 7075, 2026, or 7050 to relevant AMS/MIL specs

If you want a deeper alloy comparison and machinability data for aerospace aluminum alloys, I keep a detailed breakdown on our aluminum CNC machining materials page, including typical properties and use cases.

CNC machining capabilities for aluminum aerospace CNC parts

When you’re sourcing aluminum for aerospace CNC parts, capability matters more than anything. I run our shop to hit aerospace-grade precision, not “good enough”.

3-, 4-, and 5-axis machining for complex parts

We use 3-, 4-, and full 5-axis CNC machining to handle everything from simple brackets to complex, multi-surface aircraft components.

- 3-axis: efficient for standard profiles, plates, and simple aircraft structural parts.

- 4-axis: ideal for prismatic components, manifolds, and rotary features in one setup.

- 5-axis: perfect for lightweight aerospace structures, engine and actuation components, and complex housings where access and accuracy are critical.

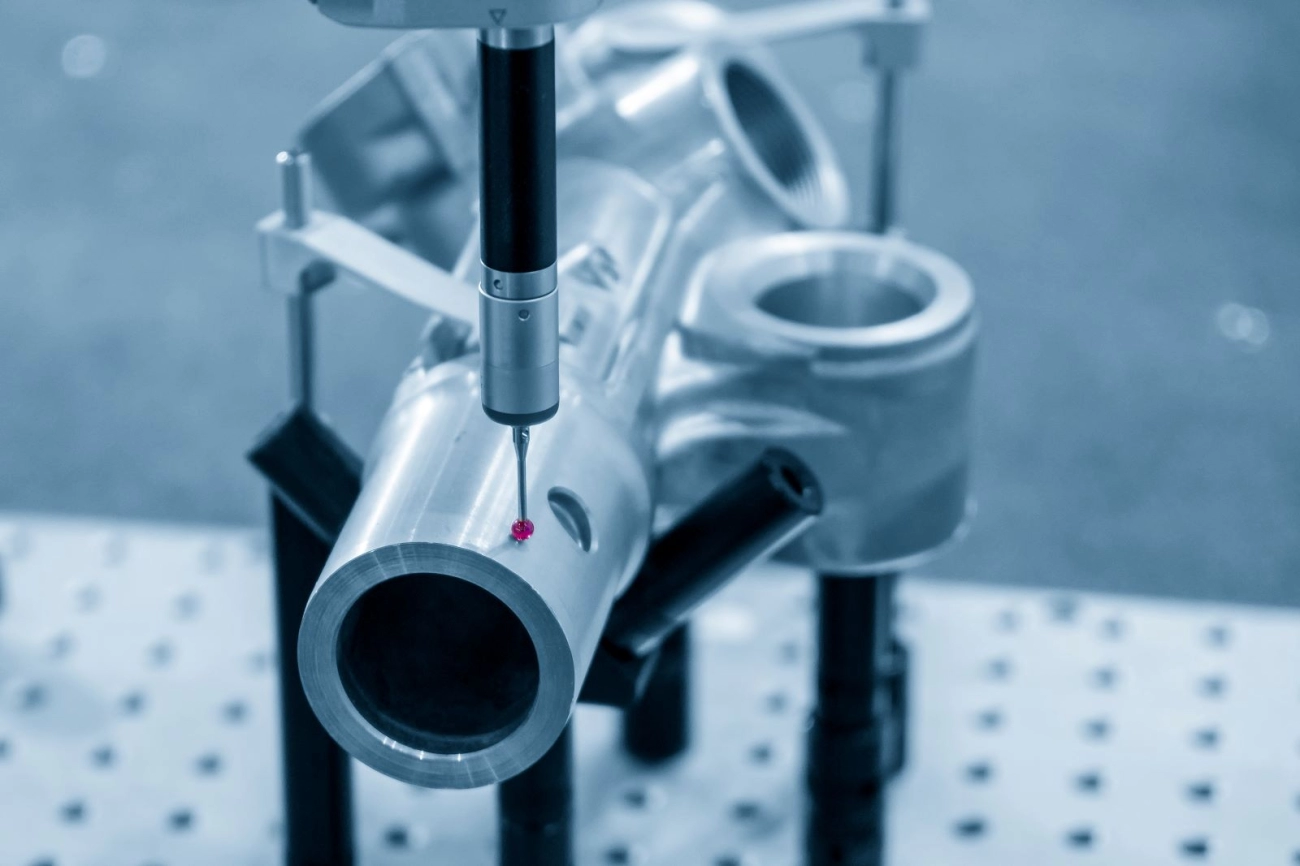

Tight tolerance aluminum CNC machining

Aerospace tolerances are tight, and we treat them that way.

- Typical tolerances down to ±0.01 mm (and tighter where required and validated).

- Full in-process inspection and final verification with CMM and advanced metrology, backed by an AS9100-aligned quality system and documented processes similar to what we outline in our quality control standards.

- Stable tooling and fixturing strategies designed around high-strength aerospace aluminum alloys like 7075, 6061, 2026, and 7050.

Thin walls, pockets, and lightweight structures

We specialize in lightweight design features that are common in aerospace aluminum CNC parts:

- Thin-wall machining without chatter or distortion.

- Deep pockets, ribs, and lattice-style structures to cut weight while keeping stiffness.

- Optimized toolpaths and cutting parameters to avoid warping, especially on large aircraft structural parts and housings.

Prototype runs to full-scale production

You can start small and scale up with the same team and process:

- Fast-turn prototypes and custom aluminum aerospace parts for design validation.

- Bridge runs for testing and low-rate initial production.

- Scalable serial production with controlled costs, repeatable quality, and stable lead times, backed by clear purchase order terms and conditions to keep programs predictable.

Whether you need 5-axis CNC milling for aluminum aircraft parts, CNC turning for aerospace aluminum fittings, or complete production support, we build our capability around aerospace requirements from day one.

Surface finishes for aluminum aerospace CNC parts

For aluminum for aerospace CNC parts, surface finish isn’t cosmetic—it directly affects fatigue life, corrosion resistance, and long‑term reliability. I spec finishes based on where the part sits on the aircraft and how it’s loaded.

Type II and Type III hard anodizing

- Type II anodizing: Good for general protection and color-coding. Typical for avionics housings, brackets, and interiors where moderate wear resistance is enough.

- Type III hard anodizing: Much thicker and harder, ideal for high-wear, high-load precision aerospace components like actuators, hinges, and sliding interfaces.

- Benefits:

- High wear resistance

- Strong corrosion protection

- Stable, repeatable finish that maintains tight aerospace tolerances when properly controlled

Chromate conversion coating (Alodine)

When we need corrosion protection plus electrical conductivity, we move to chromate conversion coating:

- Maintains conductivity for grounding, shielding, and bonding on CNC machined aircraft parts

- Thin, dimensionally stable layer—great for tight-tolerance aluminum aerospace CNC parts

- Often used as a base layer under paint or sealants for extra durability

Passivation, plating, and specialty coatings

Alongside anodizing and chromate, we also use:

- Passivation-style treatments and sealers to boost corrosion resistance in harsh flight environments

- Plating options (e.g., Ni, Zn-Ni) for wear surfaces, sealing faces, and fittings where extra hardness or lubricity is needed

- Specialty coatings (dry film lubricants, PTFE-based, etc.) for sliding, rotating, and hydraulic manifold applications where friction and galling are a concern

If a design mixes metals (for example copper components paired with aluminum), we also look at compatible finishing stacks; if you’re considering alternative materials, our precision copper machining services can be integrated into the same assembly strategy.

How finishes impact fatigue and corrosion performance

The right finish can extend service life significantly:

- Fatigue performance: Poorly controlled or overly thick hard anodize can reduce fatigue strength on high-stress 7075 aluminum aerospace parts. We manage thickness, racking, and masking around fillets and holes to protect fatigue-critical zones.

- Corrosion resistance: Anodizing and chromate conversion are your first line of defense against pitting and stress-corrosion cracking, especially on 2026 aluminum fittings and 7050 aerospace aluminum in aggressive environments.

- Dimensional impact: Finishes add thickness and can close up holes and tight clearances. We build this into the CNC program and inspection plan so your aerospace tolerances machining are maintained after finishing.

If you share your environment (marine, high humidity, de-icing chemicals, etc.) and loading conditions, I can recommend the exact finish stack for your aluminum aerospace CNC parts, balancing fatigue life, corrosion resistance, conductivity, and cost.

Quality control for aluminum aerospace CNC parts

When it comes to aluminum for aerospace CNC parts, I treat quality control as non‑negotiable. Every precision aerospace component we ship is built around four pillars: standards, traceability, measurement, and documentation.

AS9100D‑aligned quality system

We run an AS9100D‑aligned quality system from quote to final inspection:

- Controlled processes for programming, setup, machining, and inspection

- Formal FAI (First Article Inspection) on new or revised aerospace parts

- Documented NCR/CAPA process to lock in lessons learned and avoid repeat issues

This lets us plug smoothly into global aerospace supply chains that already rely on AS/EN standards for CNC machined aircraft parts.

Full material traceability and cert packages

Every aerospace aluminum alloy – 7075, 6061, 2026, 7050 and more – is fully traceable:

- Mill certs (EN/ASTM/AMS where required) tied to each heat and lot

- Material and process traceability from raw bar/plate to finished part

- Complete certification packages with CoC, material certs, special process certs, and inspection reports

If you’re mixing aluminum with titanium or stainless hardware, we align our documentation with your broader manufacturing process controls so your auditors get a clean trail.

CMM and advanced metrology for tight tolerances

Aerospace tolerances machining often means real measurement, not just calipers:

- CMM inspection for complex 3D profiles and tight GD&T callouts

- Surface finish, roundness, true position, and flatness checks for high‑strength aluminum CNC parts

- In‑process and final inspection plans matched to risk and criticality

We’re set up for thin wall aluminum machining, 5 axis CNC aerospace machining, and precision aerospace components that can’t afford rework once assembled.

Meeting AMS and MIL‑spec requirements

Aviation grade aluminum parts usually need more than just “good parts” – they need compliance:

- Machining, heat treatment, and finishing aligned to AMS specs where called out

- MIL‑spec compliant coating, hardness, and dimensional checks documented in the cert pack

- Process control records kept for audits and long‑term programs

You get CNC machined aircraft parts that don’t just meet print – they meet the AMS and MIL‑spec language your quality team and end customers expect.

Typical Aerospace Applications for Aluminum CNC Parts

Aluminum for aerospace CNC parts shows up across the entire aircraft, wherever you need high strength, low weight, and tight tolerances.

Aircraft structural parts and brackets

We machine aircraft structural parts, brackets, and mounts from 7075, 7050, 2026, and 6061 aluminum for:

- Wing and fuselage brackets

- Seat and cabin structure mounts

- Sensor, antenna, and equipment supports

These aviation-grade aluminum components keep weight down while staying strong and fatigue‑resistant under vibration and load.

Engine, landing gear, and actuation components

We produce precision aerospace components like:

- Engine accessory brackets and housings

- Landing gear linkages and supports

- Actuation system levers, clevises, and carriers

Here, 7075 and 7050 aerospace aluminum are common when you need high-strength aluminum CNC parts that still machine efficiently and hold tight aerospace tolerances.

Hydraulic blocks, fuel manifolds, and fittings

For hydraulic manifolds, fuel blocks, and fittings, aluminum is often the best mix of:

- Light weight for system efficiency

- Good machinability for complex internal passages

- Corrosion resistance with the right coating

We regularly machine aerospace hydraulic manifold and fuel system components with thin walls, deep ports, and precise sealing faces to meet AMS and MIL‑spec demands.

Avionics housings, interiors, and enclosures

Aluminum is a go-to for avionics housings, interiors, and enclosures thanks to its:

- Excellent EMI shielding

- Stable dimensions under temperature changes

- Clean cosmetic finishes with anodizing

We support lightweight enclosures, panels, and mounting frames, and can combine aluminum with engineered plastics like ABS or POM for hybrid assemblies when you need electrical insulation or weight savings in non-structural areas (see our ABS machining capability and POM machining materials).

Partnering with a specialist in aluminum aerospace CNC

When you’re sourcing aluminum for aerospace CNC parts, you don’t just need a machine shop – you need a specialist that understands airworthiness, certification, and real-world flight loads.

Engineering support for DFM and weight reduction

We get involved early on purpose. Our team reviews your models for:

- DFM (Design for Manufacturability): tightening up geometry, tolerances, and feature choices so parts are easier and cheaper to machine.

- Weight reduction: optimizing pockets, ribs, and thin walls so you hit weight targets without sacrificing strength or fatigue life.

- Alloy and temper selection: choosing between 7075, 6061, 2026, 7050 or even 6061 vs 6082 for CNC machining based on your load cases, corrosion needs, and budget.

If you prefer a visual walkthrough of how we handle aerospace parts, our short CNC process videos in the resources video library are a good starting point.

Lead time, scalability, and cost control

We design our workflow around repeatable aerospace production:

- Fast prototypes → stable production: same fixtures, same programs, same process windows from first article to volume.

- Flexible capacity: 3-, 4-, and 5-axis cells that scale from small batch cockpit brackets to ongoing runs of hydraulic manifolds.

- Cost control: smart fixture design, common tooling, and realistic tolerances so you’re not paying aerospace prices for non-critical features.

For common sourcing questions, we keep answers short and direct in our CNC manufacturing FAQ, including how we quote and schedule complex aerospace jobs.

Risk reduction and supplier reliability

Aerospace programs can’t afford surprises. We reduce your risk by:

- AS9100-minded systems: process control, traceability, and documented setups for every aerospace aluminum job.

- Clear communication: realistic lead times, early flagging of design risks, and transparent feedback on manufacturability.

- Stable quality over time: consistent machining of precision aerospace components across repeat orders, with the same alloys, the same programs, and the same inspection standards.

The result: reliable, repeatable aluminum aerospace CNC machining that supports your certification effort instead of complicating it.

Technical resources for aerospace aluminum buyers

When you’re buying aluminum for aerospace CNC parts, you need fast, clean data and clear design rules—not marketing talk. Here’s what I provide to support your team.

Aluminum alloy comparison and data sheets

I keep a full set of aerospace aluminum data ready to go so you can decide in minutes, not days.

Key data I typically share:

| Alloy | Typical Use | Strength (UTS, MPa) | Fatigue / Corrosion | Notes |

|---|---|---|---|---|

| 7075‑T6/T651 | High‑stress aircraft structural parts | ~ 510–570 | Good fatigue, fair corrosion | Great strength‑to‑weight |

| 7050‑T7451 | Thick, highly loaded sections | ~ 480–530 | Excellent | Better SCC resistance than 7075 |

| 2026‑T3/T351 | Fatigue‑critical fittings & skins | ~ 430–480 | Excellent fatigue | Common in legacy aircraft |

| 6061‑T6/T651 | General aerospace brackets & housings | ~ 290–320 | Very good corrosion | Cost‑effective “workhorse” |

| 6082‑T6 | EU/UK alternative to 6061 | ~ 290–340 | Good corrosion | Better availability in some regions |

If you need deeper property tables (modulus, shear, elongation, AMS specs), I can supply application‑focused sheets through our aerospace metal materials pages.

Design tips for CNC machining aerospace aluminum

To keep strength, weight, and cost in balance, I usually recommend:

- Wall thickness:

- 7075/7050 structural: ≥ 0.8–1.0 mm for small parts, thicker for large spans

- 6061/6082 housings: ≥ 1.0–1.5 mm for reliable machining

- Radii & pockets:

- Use generous internal radii (≥ tool radius) to avoid stress risers

- Add ribs instead of solid mass for stiffness with low weight

- Tolerances:

- Hold tight where it matters (datums, bearing bores)

- Relax non‑critical features to reduce cost and lead time

- 6061 vs 6082 for CNC machining:

- 6061: Widely used in North America/Asia, better for anodizing cosmetics

- 6082: Often easier to source in Europe, slightly stiffer, similar machinability

For more structured guidelines, I keep quick-reference design checklists in our CNC machining resources section.

Real-world case examples and performance gains

A few typical outcomes customers see when they switch to optimized aluminum aerospace CNC parts:

- Landing gear brackets (7075‑T6):

- 22% weight reduction with pocketing and rib redesign

- Same safety margin, lower cycle time using 5‑axis machining

- Hydraulic manifold blocks (7050‑T7451):

- 30% improvement in fatigue life vs 7075 in a corrosive environment

- Fewer leaks due to tighter flatness and port alignment

- Avionics housings (6061‑T6):

- 18–25% cost savings by relaxing non‑functional tolerances

- Better thermal performance with optimized wall thickness and fins

If you share drawings or a 3D model, I can usually point out 2–3 quick changes that cut both weight and machining time while staying inside aerospace standards.

How to get a quote for aluminum aerospace CNC parts

If you want a fast, accurate quote for aluminum for aerospace CNC parts, give us complete data up front. The more clear your inputs, the tighter we can lock pricing, lead time, and risk.

What files and specs to send

Send at least:

- 3D CAD files: STEP (.step/.stp) or Parasolid preferred. Native files (SolidWorks, etc.) are a plus.

- 2D drawings (PDF): With all critical dimensions, GD&T, aerospace tolerances, and surface finish callouts.

- Material spec: Exact grade and temper (e.g. 7075‑T651, 6061‑T6, 2026‑T351, 7050‑T7451) plus any AMS / MIL requirements.

- Quantity & delivery plan: Prototype, low-volume, or production? Single batch or scheduled releases?

- Quality requirements: CMM reports, FAIR, material certs, PPAP, special tests, AS9102, etc.

- Finish details: Type II or Type III hard anodizing, chromate conversion, plating, or special coatings, including color and thickness.

- Special notes: Any weight targets, no‑go areas, critical-to-function surfaces, or ITAR/export constraints.

If your parts overlap into other precision sectors like electronics housings or robotics components, share that too—our experience in electronics machining and robotics parts production often lets us suggest cheaper, more robust setups.

Checklist for faster, more accurate pricing

Before you send your RFQ, run through this quick checklist:

- [ ] 3D CAD and 2D drawing both included

- [ ] Aluminum grade + temper clearly defined

- [ ] All tight tolerances and datums marked (don’t leave them “assumed”)

- [ ] Surface finish and coating specs fully listed

- [ ] Annual usage + batch size stated

- [ ] Quality documents and certification level defined

- [ ] Packing, labeling, and export requirements noted

Send all of this in one go, and we can usually come back with a realistic price and lead time quickly—without surprises later in the project.

Reviews

There are no reviews yet.