Why Choose ZSCNC for 5-Axis CNC Gear Machining Services

We provide 5-axis CNC gear machining services for buyers who need stable quality, predictable lead times, and tight tolerance gears for demanding applications.

5-Axis CNC Gear Machining Expertise

We focus on precision gear manufacturing, not generic milling.

- Simultaneous 5-axis gear cutting for complex tooth forms

- Experience with spur, helical, bevel, hypoid, spline, and internal gears

- Familiar with AGMA 12–15 and DIN 4–6 gear quality levels

- Process engineers who understand gearbox design, not just machining paths

Typical capability focus:

| Item | Capability (Typical) |

|---|---|

| Gear module range | ~0.5 – 8 mod |

| Practical gear accuracy | Up to AGMA 12 / DIN 6 |

| Small module gear machining | High-speed 5-axis milling |

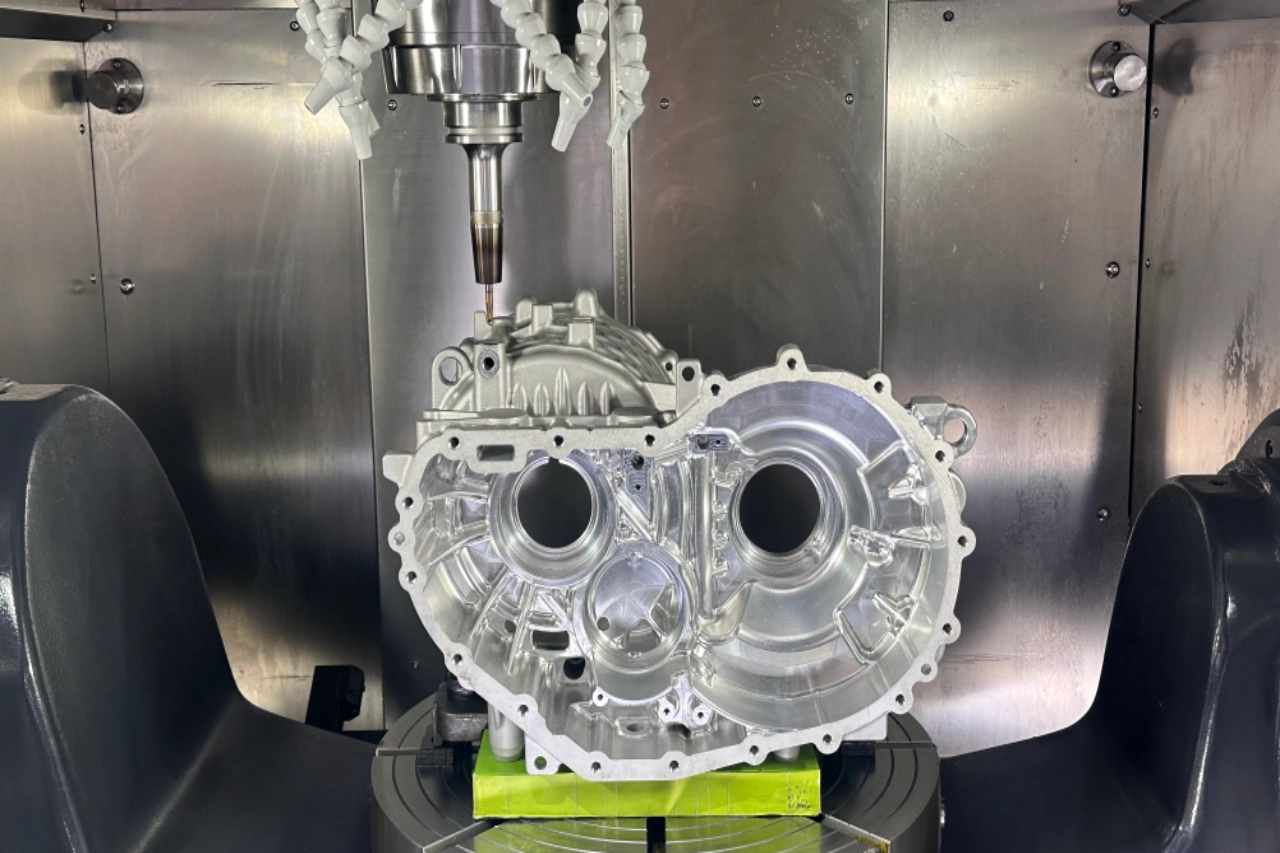

Advanced Multi-Axis CNC Equipment

We invest in multi-axis CNC as a 5-axis CNC hobbing alternative for flexible, accurate gear production.

- True simultaneous 5-axis machining (not only 3+2 positioning)

- High-speed spindles for small module and fine-pitch gears

- Rigid machines for large diameter gear machining and high-torque parts

- Integrated probing for in-process verification of critical features

Core machine features:

| Feature | Benefit for Gears |

|---|---|

| 5-axis simultaneous | Accurate complex gear geometry CNC |

| High RPM spindle | Clean finish on small teeth |

| Rotary/tilt tables | Efficient planetary gear machining |

| Automation options | Stable quality in low–mid volumes |

In-House Gear Metrology and Inspection Lab

We run an internal gear metrology services lab to keep quality measurable and traceable.

- Zeiss CMM gear measurement for critical dimensions and datums

- Interface to Klingelnberg gear inspection methods for profile and lead

- Full gear profile and lead error control for helical and bevel gears

- Dedicated checks for 5-axis splines and serrations

Inspection scope:

| Inspection Type | What We Check |

|---|---|

| Dimensional | Bore, runout, keyways, splines |

| Profile & lead | Tooth form, crowning, taper |

| Position & concentricity | Gear to shaft/hub accuracy |

| Surface finish (Ra) | Tooth flanks after machining or grind |

Quality Certifications and Industry Standards

We align our tight tolerance CNC machining services with global standards.

- Quality system built around ISO 9001 requirements

- Experience supplying to AS9100 gear machining and IATF 16949 environments

- Material and process control for carburized, nitrided, and induction hardened gears

- Documented procedures for traceability, calibration, and PPAP/FAI support

Quality framework:

| Area | Practice |

|---|---|

| Standards | ISO-based QMS; AGMA / DIN reference |

| Traceability | Heat, material, and process records |

| Documentation | Inspection reports, data logs |

| Customer audits | Open to technical and process review |

If you need a reliable 5-axis CNC gear machining partner, send us your 3D model and gear data (module, tooth count, quality class). We will review manufacturability and return a clear, data-based quote.

5-Axis CNC Gear Machining Capabilities & Specs

Max Gear Size & Module Range

Our 5-axis CNC gear machining services cover a wide size window so you can keep proto and production under one roof:

- Max OD: up to 800 mm (31.5 in)

- Face width: up to 300 mm

- Module range: approx. m0.5–m12 (smaller and larger on request)

- Small module gear machining: for robotics, EV, and precision instruments

- Large diameter gear machining: for turbines, heavy equipment, and industrial drives

Types of Gears We Machine

We use simultaneous 5-axis CNC gear cutting to handle both standard and complex gear forms:

- CNC machined spur gears

- High-precision helical gear machining

- Bevel gear 5-axis CNC (including hypoid gear machining services)

- Internal gears & spline hubs (5-axis internal gear machining)

- Worm gears and worm shafts

- Precision planetary gears, pinions, and gearbox components

- 5-axis CNC for splines and serrations

If you have a custom profile or odd geometry, we treat it as a 5-axis gear milling job, not a problem.

Supported Gear Materials

We machine gears from most materials used globally in high-performance gearboxes:

- Carbon and alloy steels (carburizing grades, case-hardening steels)

- Stainless steels & tool steels

- Titanium and nickel alloys for aerospace gear machining services

- Copper alloys and bronze for worm gears and low-noise drives

- Engineering plastics (PEEK, PA, POM, etc.) for lightweight, low-friction gears

You can send us your material spec, or we can suggest a grade based on torque, duty cycle, and target gear quality.

Tolerances, Accuracy & Surface Finish

We focus on tight tolerance gear machining for high-torque and high-speed gearboxes:

- Gear quality: up to AGMA 12–15 / DIN 4–6 (with grinding/finishing)

- Dimensional tolerance: down to ±0.01 mm on critical features (CNC & CMM verified)

- Profile & lead error control: supported by gear metrology services (Klingelnberg / Zeiss CMM gear measurement)

- Surface finish on teeth:

- After 5-axis machining: typically Ra 0.8–1.6 μm

- After grinding / superfinishing: down to Ra 0.2–0.4 μm

Superfinished gear teeth are available for low noise, low heat, and longer life in EV transmissions, motorsport gearboxes, and aerospace drives.

Heat Treatment Options for Gears

We integrate heat treatment and machining so you get consistent, traceable results:

- Carburized gear machining (case hardened for high load and fatigue resistance)

- Nitrided gear machining (wear and corrosion resistant with low distortion)

- Induction hardened gears (local hardening on teeth or flanks)

- Through hardening & tempering for general industrial power transmission gears

We can rough machine → heat treat → finish machine / grind, so your gears hit spec on hardness, distortion, and final geometry in one controlled workflow.

5-Axis vs Traditional Gear Machining

True simultaneous 5-axis vs 3+2 machining

For precision gears, we rely on true simultaneous 5-axis CNC gear machining, not just 3+2 positioning. Simultaneous 5-axis lets us keep the cutter at the ideal angle across the full tooth profile, which is critical for high-precision helical gears, bevel gears, splines, and complex forms. 3+2 can work for simple parts, but if you’re chasing AGMA 12–15 / DIN 4–6 gear accuracy, true 5-axis is the way to get there repeatably.

One-setup machining for complex gears

With 5-axis gear cutting, we usually machine all critical features in one setup – teeth, reference bores, faces, and key datums. That means:

- No repeated re-clamping or manual re-alignment

- Better control of concentricity, runout, and position

- Faster changeovers for prototype and low-volume gear runs

For complex bevel gear 5-axis CNC work, planetary gear components, and gearbox housings, this single-setup approach is a big win in stability and accuracy.

Accuracy, cycle time, and cost benefits

Simultaneous 5-axis machining helps us:

- Hold tight tolerances on profiles and leads

- Cut cycle time by reducing non-cutting movements and setups

- Lower overall cost per gear on complex or multi-feature parts

Compared to traditional hobbing plus multiple secondary operations, 5-axis CNC is often more economical for custom gear prototyping, high-mix jobs, and complex gearbox component machining, especially when you factor in reduced fixtures and inspection corrections.

Surface quality and chip evacuation advantages

The extra axes also give us better control over surface finish and chip flow. By tilting the tool intelligently during multi-axis CNC gear milling, we improve:

- Surface quality on tooth flanks (ideal before gear grinding or superfinishing)

- Tool life, thanks to better cutting angles

- Chip evacuation on deep teeth, internal gears, and small module gears

This is especially important on hard-to-machine materials like tool steels, titanium, and nickel alloys, where heat and chip packing can quickly kill tools and surface finish. When needed, we tie this in with our dedicated quality control and inspection workflows, supported by our in-house systems described on our quality control page.

Gear Quality Assurance & Inspection

When we run 5-axis CNC gear machining services, we treat gear quality and inspection as non‑negotiable. Every gear goes through controlled, documented checks so it performs reliably in real gearboxes, drives, and transmissions.

Gear inspection equipment and methods

We combine gear metrology services with standard precision inspection:

- Zeiss CMM gear measurement for full 3D checks

- Klingelnberg / equivalent gear inspection for profile, lead, and pitch

- Dedicated gauges for splines, serrations, and internal gears

- Surface finish checks for superfinished gear teeth after grinding or lapping

This lets us verify critical features on spur, helical, bevel, worm, hypoid, and planetary gears.

Dimensional, profile, and lead inspection

We inspect every critical parameter that drives AGMA 12–15 and DIN 4–6 gear accuracy:

- Dimensional checks: bore, PCD, runout, keyways, splines, hubs

- Profile error and lead error: checked tooth-by-tooth where needed

- Pitch, backlash, and concentricity: controlled for high‑accuracy gear production

If you need documented tolerances for aerospace gear machining services, EV transmission gears, robotics gear machining, or high‑torque industrial power transmission gears, we can lock them in and prove them.

Material and heat-treatment traceability

We maintain full material and heat‑treatment traceability from raw stock to finished gear:

- Mill certificates for carbon steel, alloy steel, stainless, tool steel, titanium, nickel alloys, bronze, engineering plastics (PEEK, etc.)

- Batch records for carburized, nitrided, and induction hardened gears

- Recorded hardness and case‑depth results tied to your part number and PO

You always know exactly what went into each batch of gears and how it was processed.

First-article inspection for gears

For new 5‑axis gear cutting or design changes, we run a structured First Article Inspection (FAI):

- Full dimensional report from CMM / gear checker

- Verification of surface finish, material, and heat treat

- Signed inspection pack before we move into low‑ or medium‑volume gear production

This gives you a stable, proven baseline for ongoing orders and long‑term supply on critical gearbox component machining.

Industries and Gear Applications

Aerospace Gear Machining Services

I use 5-axis CNC gear machining services to hit tight tolerances for aerospace gear sets, actuators, flap drives, and gearbox components.

- Work to AGMA 12–15 / DIN 4–6 levels where needed

- Handle high-strength alloys, heat-treated and inspected with full traceability

- Support simultaneous 5-axis machining for complex bevel, hypoid, and spline features

Automotive and EV Transmission Gears

For automotive and EV customers, I focus on high-accuracy gear production with stable quality and predictable lead times.

- CNC machined spur gears, helical gears, planetary gears, splines

- Support EV transmission gear manufacturing with low noise and high-efficiency tooth profiles

- Options for carburized, nitrided, and induction hardened gears

Robotics and Automation Gear Solutions

Robotics and automation need quiet, precise, low-backlash gears, and that’s where multi-axis CNC gear milling shines.

- Small module gear machining for compact gearboxes

- Precision planetary gear machining and 5-axis CNC for splines and serrations

- Ideal for robot joints, AGV drives, automation actuators

Energy, Oil & Gas, and Turbine Gears

For energy and heavy industry, I machine gears built to handle shock loads and long duty cycles.

- Industrial power transmission gears, turbine gears, pump and compressor gears

- Large diameter gear machining with controlled profile and lead error

- Materials from alloy steels to nickel alloys for harsh environments

Motorsport and Racing Gearboxes

Racing teams and performance builders come to me for gears that can take high torque and high RPM without failure.

- High-torque gearbox gears and custom gear prototyping

- Options for superfinished gear teeth, gear grinding, honing and lapping

- Fast turnarounds for prototype gear machining service and low-volume race sets

Gear Materials We Machine for 5-Axis CNC Gear Machining Services

We machine gears in a wide range of materials so you can match performance, weight, and cost for your gearbox or transmission. With our 5-axis CNC gear machining services, we hold tight tolerances on everything from small module precision gears to large diameter, high‑torque parts.

Carbon and Alloy Steel Gears

We produce carburized, nitrided, and induction-hardened carbon and alloy steel gears for heavy-duty, high-torque gearbox applications. These materials are ideal for industrial power transmission gears, EV and automotive gears, and AGMA 12–15 quality levels where strength and fatigue life matter most.

Stainless Steel and Tool Steel Gears

For corrosion‑resistant and high-wear environments, we machine stainless steel and tool steel gears, splines, and serrations. Our team works daily with common stainless steel machining grades for food, medical, marine, and energy projects that need both durability and clean surfaces.

Titanium and Nickel Alloy Gears

We support titanium and nickel alloys for lightweight, high‑temperature, and aerospace gear machining services. These materials are ideal when you need high-strength, low‑weight solutions for robotics, aircraft actuators, or extreme environments.

Copper Alloy and Bronze Gears

We machine copper alloy and bronze gears for quiet running, good lubrication behavior, and solid wear resistance. These are common in worm gear 5-axis manufacturing, hypoid gear machining services, and high-precision, low-noise motion control systems.

Engineering Plastic Gears (PEEK, etc.)

For lightweight, low‑noise, and cost‑effective solutions, we produce engineering plastic gears in PEEK, POM, ABS, and other technical plastics. Materials such as high‑stability POM engineering plastic work well in compact robotics gear machining, consumer products, and low-lubrication drives where weight and noise must stay low.

Production Capacity and Lead Times for 5-Axis CNC Gear Machining

Prototype Gear Machining

We handle fast prototype gear machining on our 5-axis CNC machines for trials, validation, and design changes. You can send us 3D models or existing gear samples, and we’ll machine high-precision prototypes that match real production quality, not just “demo parts.”

Low- and Medium-Volume Gear Production

Our 5-axis setup is ideal for low- and medium-volume gear production, including complex helical, bevel, and spline gears. We focus on:

- Stable quality across repeat orders

- Flexible batch sizes for gearbox assemblies and spares

- Quick changeovers for multiple gear variants

Monthly Gear Output Capacity

With multiple multi-axis CNC centers and a streamlined manufacturing process, we support:

- Prototypes: from 1 piece

- Small runs: 10–200 gears

- Medium runs: up to several thousand gears per month (depending on size and complexity)

Lead Time Factors and Rush Options

Lead times depend on:

- Gear size, module, and complexity

- Material availability (we stock common steels, aluminum, and titanium)

- Heat treatment and finishing needs

For urgent projects, we offer rush 5-axis CNC gear machining services with:

- Priority programming and setup

- Parallel machining on multiple machines

- Fast inspection and documentation support

Send your drawings or STEP files, and we’ll confirm a realistic lead time and capacity window before you commit.

Value-Added 5-Axis CNC Gear Machining Services

On top of 5-axis CNC gear machining services, we stack a full set of value-added processes so you get gears that are ready to run, not just ready to measure.

Gear design optimization & DFM

We review your 3D models, drawings, and specs and give direct feedback on:

- Tooth form, chamfers, and fillets for better tool access

- Wall thickness, hubs, and keyways for strength and machinability

- Material and heat-treatment choices vs. target life and cost

This design-for-manufacturing support helps cut cost, risk, and lead time before we machine the first gear. You can also send general CNC work through our broader CNC machining services if you’re still refining the full gearbox design.

Reverse engineering from gear samples

If all you have is a sample gear, we can rebuild it:

- 3D scanning and CMM/gear metrology to capture tooth profile and lead

- Measurement of pitch, runout, module/DP, pressure angle, and modifications

- Creation of full CAD and manufacturing drawings for repeatable production

This works well for legacy, imported, or undocumented gears where no data exists.

Post‑machining grinding and finishing

To reach AGMA 12–15 or DIN 4–6 gear accuracy, we add finishing after 5-axis gear cutting:

- Gear grinding, honing, and lapping

- Superfinishing of flanks to lower noise and improve efficiency

- Deburring and edge conditioning for safer handling and smoother meshing

We match the finishing route to your noise, efficiency, and durability targets.

Gear assembly and functional testing

We don’t stop at single parts. For matched gear sets and gearboxes we offer:

- Assembly of gears, shafts, bearings, and carriers

- Backlash, contact pattern, and rotational torque checks

- Functional run tests under load where required

This lets you receive pre-validated gear assemblies that drop straight into your line, cutting time spent on incoming inspection and troubleshooting.

5-Axis CNC Gear Machining Case Studies

Aerospace Gear Project Results

For aerospace gear machining services, we use simultaneous 5-axis CNC and full gear metrology to keep tight tolerance gears stable over long runs.

- Application: flight‑critical gearbox gears

- Specs: up to AGMA 12–13 / DIN 6 quality, controlled profile and lead error

- Result: weight reduced by ~12%, noise lowered, and 100% traceable material and heat treatment for audit-ready documentation

EV Transmission Gear Example

For EV transmission gear manufacturing, we focus on low noise, high efficiency, and repeatability.

- Application: high-speed EV reduction gears and splines

- Process: 5-axis CNC gear cutting + post-machining grinding where needed

- Result: improved gear mesh, lower NVH, tighter backlash, and shorter cycle time vs traditional hobbing-only flow

Robotics Precision Gear Case

For robotics gear machining, the goal is smooth motion and zero-play feeling.

- Application: precision planetary gears, internal gears, and splines for automation and cobots

- Highlights: small module gear machining, tight tolerance CNC machining services, superfinished gear teeth

- Result: higher positioning accuracy, longer service life, and lower wear in high-duty cycles

Turbine & Industrial Gear Project

On turbine and industrial power transmission gears, we use 5-axis CNC as a flexible alternative to dedicated hobbing.

- Application: energy, oil & gas, and high‑torque gearbox components

- Materials: alloy steel, carburized and nitrided gears, induction hardened gears

- Result: reduced lead time on custom and spare gears, high-accuracy gear production for large diameter gear machining with stable quality across batches

Customer Feedback and Certifications for 5-Axis CNC Gear Machining Services

Engineers who work with us on 5-axis CNC gear machining services care about one thing: consistent, predictable quality. We get repeat orders from aerospace, EV, and robotics customers because our precision gear manufacturing stays stable from prototype to series runs, even on tight tolerance gear machining and high-accuracy gear production.

Customer Testimonials from Engineers

Our engineering customers usually highlight three things:

- Stable accuracy on CNC machined spur gears, helical gears, and splines over long projects

- Clear feedback loops on DFM and tolerance calls for complex, simultaneous 5-axis machining gears

- On-time delivery for critical gearbox component machining and replacement gears

Most of our long-term partners treat us as their external 5-axis gear cutting and prototype gear machining service, not just a job shop.

Industry Compliance and Audits

We run our 5-axis CNC gear machining under strict quality systems to support demanding industries:

- ISO 9001 gear machining for general industrial and power transmission gears

- AS9100 gear machining supplier level controls for aerospace gear machining services

- IATF 16949 gear manufacturer practices for automotive and EV transmission gear manufacturing

We support customer audits, process walk-throughs, and full documentation, including how we handle drawings and models in line with our data protection and privacy policy.

Long-Term Supply and Reliability

For long-life programs, we set up 5-axis CNC gear machining cells to keep your parts repeatable over years, not just batches:

- Stable process windows for carburized, nitrided, and induction hardened gears

- Documented process parameters for repeatable AGMA 12–15 / DIN 4–6 gear accuracy

- Capacity planning to protect delivery on low- and medium-volume gear runs

Our goal is simple: once a gear is qualified, you don’t have to worry about it again—just issue release orders and keep your line running.

5-Axis CNC Gear Machining FAQ

Design limits and smallest module

We focus on tight-tolerance, high-precision gears, not commodity parts. Typical design limits:

- Smallest module: down to m = 0.3–0.4 (depending on material and width)

- Largest diameter: up to Ø 600–800 mm (gear type dependent)

- Max face width: usually up to 150–200 mm

Send us your gear drawing or 3D model and we’ll confirm if we can hold your spec and gear quality class (AGMA / DIN).

Helical and bevel gear capabilities

We use simultaneous 5-axis gear machining instead of traditional hobbing for complex geometries:

- CNC machined spur gears & helical gears (including high-helix and crowned teeth)

- Bevel and hypoid gear machining services for gearboxes and power transmission

- 5-axis spline machining, serrations, and internal gear machining for planetary sets

If you need aerospace gear machining services, EV transmission gears, or robotics gear machining, we can handle the tooth form and alignment.

Gear grinding and finishing options

When you need better than milled finish or AGMA 12–15 / DIN 4–6 accuracy, we add finishing:

- Gear grinding after CNC machining for higher accuracy and low noise

- Gear honing and lapping for smooth running and reduced friction

- Superfinished gear teeth to improve efficiency and fatigue life

We match the finishing route to your application: high-torque gearboxes, motorsport, aerospace, or quiet EV drives.

Material, tolerance, and inspection questions

We machine and control tight tolerance gear components across a wide material range:

- Materials: carbon and alloy steel, stainless and tool steel, titanium, nickel alloys, bronze, copper alloys, and engineering plastics (PEEK, etc.)

- Heat treatment: carburized, nitrided, induction hardened gears

- Accuracy: tight tolerance gear machining with full gear metrology services

- Inspection: Klingelnberg gear inspection, Zeiss CMM gear measurement, profile & lead error control, and material traceability

Tell us your tolerances, gear quality level (AGMA / DIN), and any special inspection requirements – we’ll tell you up-front if we can meet them.

Ordering, quoting, and NDA process

We keep the process simple and safe for your IP:

- For instant quotes for 5-axis CNC gear machining, upload:

- 2D drawing (PDF/DWG/DXF) with tolerances & gear data

- 3D model (STEP/IGES)

- Material, quantity, and required lead time

- Typical response time: 24–48 hours for most RFQs

- NDA: We sign your NDA or provide ours before you share sensitive gearbox or transmission data

- After approval, we lock specs, launch prototype gear machining or low- and medium-volume gear production, and keep you updated until delivery.

Instant Quote for 5-Axis CNC Gear Machining

What to Upload for Fast Quoting

To get a fast and accurate quote for our 5-axis CNC gear machining services, please upload:

- 2D drawings (PDF) with dimensions, tolerances, gear standard (AGMA / DIN)

- 3D models (STEP/IGES) of gears, splines, or gearbox components

- Gear data: module/DP, tooth count, pressure angle, helix angle, face width

- Material and heat treatment (carburized, nitrided, induction hardened, etc.)

- Target quantity (prototype, low-volume, or medium-volume) and required lead time

If you need reverse engineered gears, upload clear photos and any sample data you have. We can sign an NDA on request before you send anything.

Typical Response Times and Workflow

We keep the quote process simple and fast for global customers:

- Quote time: Most 5-axis gear cutting and precision gear manufacturing quotes in 24–48 hours

- Technical review: Our engineers check manufacturability, tolerances, and inspection needs

- DFM feedback: If we see risk on tight tolerance gear machining or small module gear machining, we suggest small design tweaks

You get a clear breakdown: machining, heat treatment, finishing (grinding, honing, superfinish), inspection level, and shipping options.

From RFQ to Gear Delivery

Once you accept our quote, we move quickly:

- Confirmation & PO – Lock in scope, price, lead time, and quality level (e.g. AGMA 12–15, DIN 4–6).

- Process planning – Select machines and fixtures for simultaneous 5-axis machining of gears, splines, and gearbox parts.

- Production & inspection – Run machining, heat treatment, and any gear grinding; verify with CMM and gear metrology services.

- Packing & shipping – Export-ready packing for global delivery, with full inspection reports and material traceability included.

From custom gear prototyping to high-accuracy gear production, we keep you updated at each step so you know exactly where your order stands.

Reviews

There are no reviews yet.