ZSCNC PEEK High-Performance Engineering Plastics

Discover exceptional durability, chemical resistance, and thermal stability with ZSCNC’s advanced PEEK solutions. Engineered for precision and reliability in demanding industrial applications.

Thermal Resistance and Chemical Stability of PEEK

Exceptional Thermal Resistance

PEEK exhibits outstanding thermal resistance with a continuous service temperature up to 250°C. This ensures reliable performance even in high-heat industrial environments. For more insights on various materials, visit our dedicated section.

Chemical Stability Under Harsh Conditions

The chemical structure of PEEK provides superior resistance to acids, bases, and organic solvents, making it ideal for demanding chemical applications.

Molecular Integrity

The stability of PEEK’s molecular chains ensures long-term durability under thermal and chemical stress.

Performance Metrics

Data-driven insights confirm PEEK’s capability to maintain mechanical strength and chemical resistance under extreme conditions.

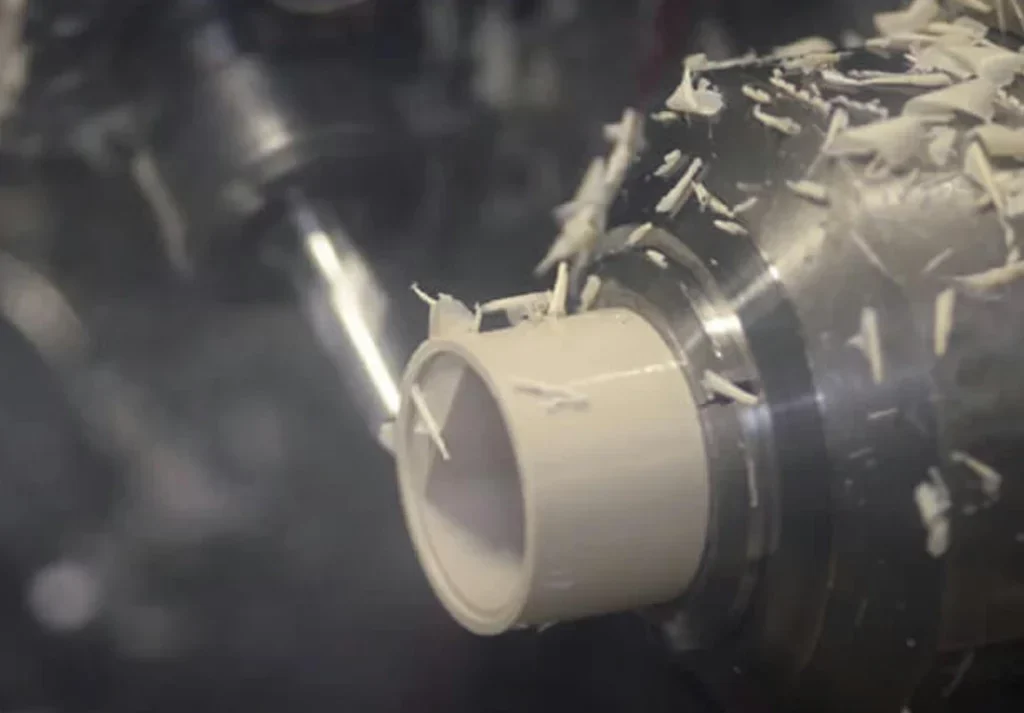

Precision CNC Machining Capabilities and Structural Adaptability of PEEK

At ZSCNC, we specialize in precision CNC machining of PEEK, achieving tolerances down to microns for complex, high-performance components. Our advanced processes ensure excellent structural integrity and dimensional accuracy.

PEEK’s unique adaptability enables it to maintain strength and chemical resistance under extreme temperatures and mechanical loads, making it ideal for aerospace, medical, and engineering applications.

Leveraging state-of-the-art 5-axis CNC equipment, we deliver custom parts with superior surface finish and consistent quality. Our expertise in tool path optimization reduces waste and lead times.

Industry Applications and Typical Use Cases of PEEK Components

Aerospace & Automotive

PEEK components withstand extreme temperatures and chemical exposure, ideal for aerospace and automotive parts requiring durability and lightweight design.

Medical Devices

Its biocompatibility and sterilization resistance make PEEK the preferred choice for surgical instruments, implants, and diagnostic tools.

Electronics & Electrical

Superior electrical insulation and thermal stability allow PEEK to excel in connectors and insulators in harsh industrial environments. For more details about our industry expertise, please visit our About page.

Precision Machining

CNC technology enables high-precision PEEK parts for complex components in industrial machinery.

Custom Fabrication

Versatile fabrication capabilities produce tubing, rods, and sheets tailored for demanding engineering applications.

Industrial Assembly

PEEK’s chemical resistance and mechanical strength make it ideal for seals, insulators, and bearings in industrial assemblies.

ZSCNC’s expertise in PEEK component manufacturing delivers superior quality solutions for complex industry challenges. Reliable, durable, and engineered for high performance.

PEEK Material VS Other Plastics

Superior High-Temperature Resistance

PEEK withstands continuous temperatures above 250°C, outperforming typical engineering plastics.

Exceptional Mechanical Strength

PEEK offers higher tensile strength and stiffness compared to many other plastics, ideal for demanding applications.

Chemical and Wear Resistance

PEEK is highly resistant to chemicals and abrasion, extending component life in harsh environments.

Precision Machinability

PEEK allows material tight tolerance machining for complex components, perfect for high-end engineering needs.

Cost-Effective Long-Term Investment

Though premium priced, PEEK reduces maintenance and replacement costs significantly over time.

Versatile Application Range

PEEK suits aerospace, medical, and automotive markets due to its diverse performance profile.

Quality Control and Inspection Essentials for Precision PEEK Components

Ensuring consistent production of precision PEEK components requires rigorous quality control.

Our inspection process at ZSCNC involves advanced measurement techniques that verify dimensional accuracy within microns.

- Visual and surface defect inspection under controlled lighting conditions

- Dimensional verification using CMM machines for exact tolerances

- Material property testing to ensure compliance with high-temperature resistance standards

- Documentation and traceability for process transparency

Precision Measurement

Employing Coordinate Measuring Machines (CMM) to achieve micron-level accuracy.

Material Integrity

Testing thermal and mechanical properties to maintain peak PEEK performance.

Process Traceability

Comprehensive documentation ensures quality consistency and regulatory compliance.

Customized Service Workflow and Collaborative Development

- 1

Tailored Consultation

Collaborate to assess your specific manufacturing requirements and define clear objectives.

- 2

Collaborative Design

Engage with our engineering team to co-develop CNC machining services, ensuring precision and cost efficiency.

- 3

Prototyping & Testing

Rapid prototype manufacturing followed by thorough validation to meet your quality standards.

- 4

Full-scale Production

Seamless transition to high-volume manufacturing with continuous feedback for optimization.

- 5

Ongoing Support

Dedicated customer service and engineering assistance ensure sustained product excellence.