Stainless Steel CNC Machining Precision

Corrosion Resistant High Strength Stainless Steel Materials Tailored for Long Term Service in Harsh Environments

- Superior corrosion resistance ideal for humid chemical and marine environments

- High strength and fatigue resistance for pressure and cyclic stress parts

- Precision CNC machining with tight tolerances and complex geometries

- International standard materials compliant with mainstream stainless steel grades

Stainless Steel Material Types & Performance Overview

Austenitic Stainless Steel 304 & 316 Series

Features excellent corrosion resistance, formability, stable welding, and easy polishing.

Applications:

Food equipment casings, pipe fittings, brackets, decorative and structural parts.

Machining Focus: Manage cutting heat and tool wear for excellent surface finish and precision in CNC-machining.

Martensitic Stainless Steel 410 & 420 Series

Heat treatable for high hardness, suitable for wear-resistant and load bearing parts.

Applications:

Valve cores, shafts, fasteners, mechanical transmission components.

Machining Focus: Dimensional control and geometric accuracy pre/post heat treatment using milling techniques.

Precipitation Hardening Stainless Steel 17-4PH

Balanced strength and corrosion resistance, ideal for high-demand structural components.

Applications:

Aerospace components, pressure system connectors, high-strength supports.

Machining Focus: Strict heat treatment control combined with fine finishing processes such as turning.

High Temperature Special Media Stainless Steel

Reliable performance under high temperatures and corrosive media including chlorides and weak acids.

Applications:

Offshore devices, chemical piping, high temperature fluid components.

Machining Focus: Ensure batch consistency and traceability of material certifications with advanced five-axis machining processes.

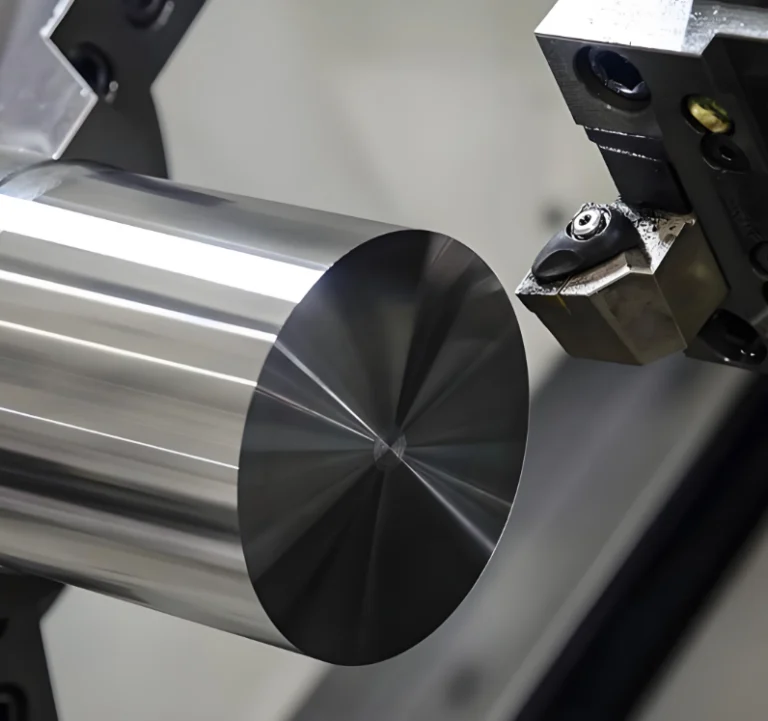

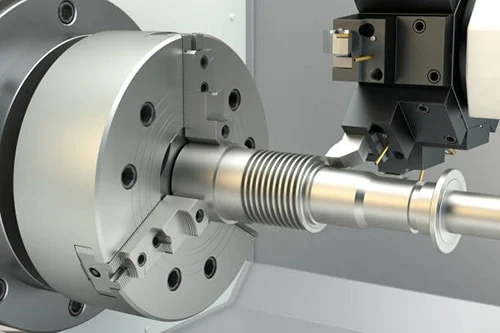

Stainless Steel Precision Machining Capabilities

Advanced CNC turning and milling with tight tolerances for complex components and structural applications.

CNC Turning Applications

- Shafts, Rings & Sleeves: Precision cylindrical components with tight roundness control.

- Valve Bodies: Complex geometries from rough to finish turning machining in one setup.

- Size Range: Small precision parts to medium-size structural components.

- Quality: Dimensional consistency with tight roundness and coaxiality control.

Multi-Axis Composite Milling

- Complex Contours: Irregular cavities and multi-faceted geometries machined with precision.

- One-Setup Advantage: Multi-face clamping reduces setup errors and improves repeatability.

- Mounting & Sealing: Precise machining of critical surfaces for functional assembly.

- Surface Finish: Controlled roughness meeting demanding application requirements.

Quality Control & Tolerance Expertise

Advanced Inspection

Dimensional, positional, and surface finish verification using state-of-the-art measurement tools and equipment.

Process Monitoring

Documented parameter control from first piece through mass production with scheduled sampling inspections.

Precision Fits

Tight tolerance capability suitable for precision interference fits and critical sealing structures.

Consistency Assurance

Stable, repeatable processes delivering consistent quality across prototyping and production runs.

Typical Application Scenarios for Stainless Steel Parts

Fluid Valve Components

Valve bodies, seats, fittings, pipe connectors for water, oil, mild corrosive media, and high-pressure systems.

Design focus: sealing surface quality, thread precision, stress corrosion resistance.

Industrial Equipment Structural Parts

Support brackets, mounting bases, guide assemblies designed for long-term operation under vibration and cyclic loads using robust steel materials.

Design focus: structural strength, fatigue lifespan, assembly dimension matching.

Outdoor High Humidity Environment Components

Covers, mounts, brackets, and outdoor enclosure structures exposed to rain, humid air, and saline breeze.

Design focus: surface treatment, weather resistance, maintenance intervals.

Cleanliness Critical Equipment Parts

Contact housings, supporting frameworks, and non-media contact components for hygiene-conscious systems.

Design focus: surface finish quality, chamfers, cleaning convenience.

Surface Treatment Corrosion Resistance Enhancement Solutions

Mechanical Chemical Processing

Deburring and chamfering improve assembly safety and enable smooth mechanical operation.

Polishing and fine grinding enhance surface roughness, mating quality, and appearance. These refinements reflect our focus on quality to meet industry standards.

Passivation & Protective Coating

Passivation treatments fortify passive film stability to slow oxidation and extend life, a process detailed in our quality control standards.

Cleaning and anti-rust oils ensure durability during long shipping and storage periods.

Special Surface Requirements

Matte and high gloss finishes are selected based on environment and functional needs. Understanding these needs is part of our company profile.

Localized treatments focus on critical surfaces to optimize cost and performance.

Quality Control & International Export Excellence

ZSCNC delivers certified manufacturing with rigorous quality checkpoints, material traceability, and compliance with international standards. Trusted by leading clients across Japan, USA, and Europe.

Quality Management

Material traceability with certified documentation. Key checkpoints embedded in every production step for consistent process control.

Material Traceability

Receiving batch documentation with full certification. Complete visibility from raw metal materials through finished components.

Pre-Shipment Inspection

Sampling and visual inspection with optional reporting. Every shipment verified to customer specifications.

Standards Compliance

International materials standards and customer drawing conventions. Direct alignment with overseas inspection protocols.

Precision Manufacturing & Export Capability

Precision CNC Machining as laser-cutting

Advanced CNC technology for complex geometries and tight tolerances. Multi-axis machining capabilities for demanding applications.

- ✓ Stainless steel and specialty alloys

- ✓ Surface finishing and treatments

- ✓ Rapid prototyping to volume production

Global Export Partnerships

Long-term supply relationships across multiple continents. Deep understanding of client concerns regarding stability, protective packaging, and documentation requirements.

Japan

Established supplier

USA

Active partnerships

Europe

Multiple markets

Custom Stainless Steel Project Cooperation Guide

1. Requirement Discussion

Define intended use, operating environment, expected lifecycle, and order quantity range to align project scope.

2. Technical Assessment

Perform feasibility studies for materials, structural design, and tolerance demands with expert analysis that supports precision CNC machining.

3. Quotation Proposal

Receive detailed proposals covering material options, milling machining strategies, and lead time estimates.

4. Sample Verification

Confirm sample dimensions, assembly fit, and gather user feedback for quality assurance in turning machining processes.

5. Formal Mass Production

Schedule stable, long-term supply aligned with contractual agreements for consistent delivery.

Key Customer Information

- Drawings and technical specifications including tolerances, surface finish, and heat treatment notes

- Forecasted order volume and batch scheduling to optimize CNC machining and production methodology

- Usage environment and special constraints such as temperature, media type, and hygiene standards