ZSCNC's Quality Control Commitment

Delivering precision manufacturing through rigorous quality inspections. We ensure every prototype meets exacting standards, minimizing defects and maximizing client satisfaction. Learn more about our company and how we uphold quality.

Quality Management System Overview

Quality Policy and Strategic Objectives

At ZSCNC, our quality policy ensures continual improvement and customer satisfaction through precise standards and strategic goals aligned with industry best practices.

Organizational Structure and Roles

Our clearly defined organizational roles empower accountability and collaboration to uphold the quality management system effectively across all departments.

Standards and Compliance

ZSCNC maintains rigorous compliance with ISO 9001 standards, ensuring all processes meet global quality benchmarks and regulatory requirements.

Incoming Materials & Supplier Quality Control

Supplier Qualification and Assessment

Ensure supplier compliance through rigorous qualification processes and thorough assessments. Identify risks early and maintain consistent quality across your supply chain.

Incoming Inspection Procedures

Conduct precise inspections on all incoming materials using standardized protocols. Detect defects promptly to prevent production delays and costly rework.

Nonconforming Material Handling

Implement controlled processes for managing nonconforming materials. Track, segregate, and dispose or rework materials in compliance with your quality standards.

Comprehensive Quality Control & Operation Monitoring

Pre-Process Quality Planning

Establish robust quality parameters before production. ZSCNC integrates planning to prevent defects and optimize manufacturing process workflow.

First Article & In-Process Patrol Inspection

Perform initial product validation and ongoing inspections to ensure consistent adherence to specifications.

In-Process Quality Control & Operation Monitoring

Monitor operations in real time to detect deviations quickly, ensuring minimal defects and maximum throughput.

Deviation Handling and Correction

Systematic investigation and correction processes reduce recurrence, driving continuous quality improvement.

Final Inspection and Shipment Release Standards

Final Inspection Items and Methods

ZSCNC enforces comprehensive inspection of all dimensions, surface finishes, and material properties using advanced metrology and calibrated equipment. Each item undergoes strict visual and functional tests to ensure compliance.

Shipment Decision and Categorization

Shipments are categorized by quality status: approved, conditional release, or reject. Only approved products proceed to shipment, adhering to stringent packaging and documentation protocols for traceability and security.

Customer Quality Engagement

ZSCNC partners closely with customers, offering real-time quality reports and feedback loops. Joint audits and visits reinforce transparency and continuous improvement in customer quality delivery.

Inspection Equipment and Measurement Capability

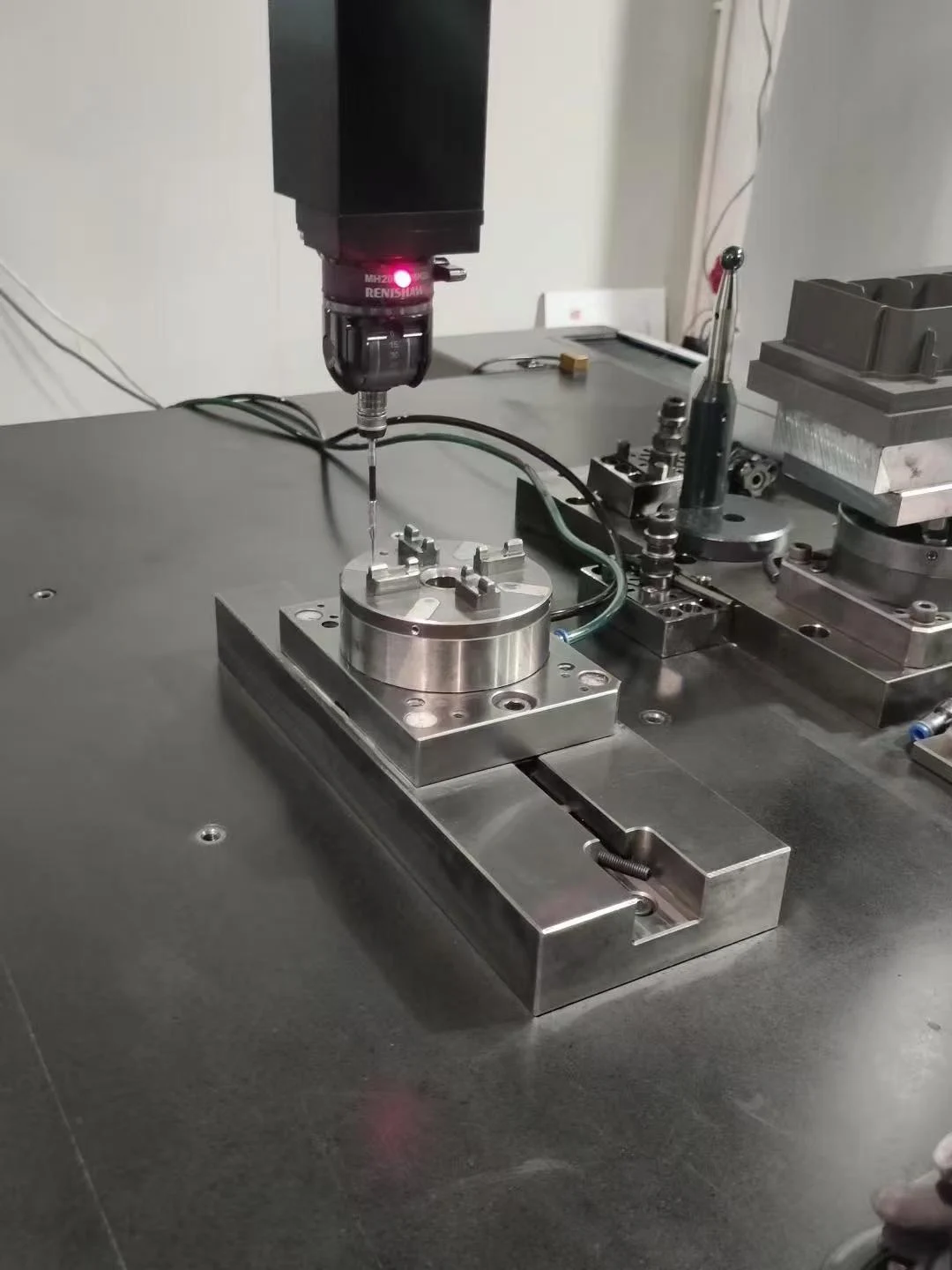

Major Inspection Equipment Types

ZSCNC utilizes advanced inspection equipment including CMMs, optical comparators, and surface roughness testers. For enhanced quality assurance, our products integrate these tools to ensure precision and reliability from production through final quality validation.

- Coordinate Measuring Machines (CMMs)

- Optical and Video Measurement Systems

- Surface Roughness and Profile Measurement

- Non-Destructive Testing Instruments

Measurement Accuracy and Tolerance Range

ZSCNC guarantees strict adherence to measurement accuracy standards within tight tolerance ranges. Our precision instruments achieve repeatability within microns to uphold quality consistency.

- Accuracy down to ±0.001 mm for critical dimensions

- Statistical Process Control tracking

- Regular calibration to maintain measurement integrity

Calibration and Maintenance Protocols

ZSCNC implements rigorous calibration schedules and preventive maintenance protocols. Calibration is performed by certified technicians using traceable standards. Maintenance workflows minimize downtime and assure ongoing equipment precision.

Scheduled Calibration

Periodic calibration intervals aligned with ISO 17025 standards.

Preventive Maintenance

Routine inspections and cleaning protocols prevent unexpected failures.

Traceability & Documentation

Comprehensive calibration records maintain compliance and audit readiness.

Traceability & Documentation Management at ZSCNC

Batch Coding and Production Logs

Ensure accurate batch identification with real-time coding and digital production logs. Streamline compliance and enhance operational transparency with our products designed for manufacturing excellence.

Inspection Reports and Record Retention

Manage comprehensive inspection reports and securely retain records to meet regulatory standards and facilitate audits efficiently.

Change and Version Control

Maintain strict version control and change management to guarantee traceability of every update across all documentation.

Customer Quality Alignment & Continuous Improvement

Pre-Project Quality Discussions

Establish clear customer quality expectations and specifications

with customers before project initiation to ensure alignment.

Quality Feedback & Correction Workflow

Implement structured feedback loops and corrective actions

to address quality issues swiftly and transparently.

Continuous Improvement & Performance Tracking

Monitor quality performance metrics consistently to drive

ongoing process enhancements and exceed customer expectations.

Quality Culture and Team Competence at ZSCNC

Quality First Corporate Philosophy

At ZSCNC, quality is our foundation. We embed quality in every process, ensuring excellence and reliability in all deliverables. Learn more about our about page to understand our commitment.

Training and Skill Development Programs

Our comprehensive training initiatives empower teams to advance skills and adapt to industry best practices, driving continuous improvement.

Quality Awareness Incentives

We recognize and reward commitment to quality to foster motivation and accountability across all departments at ZSCNC. For further inquiries, visit our contact page.

ZSCNC Global Market Quality Assurance Commitment

Comprehensive Quality Assurance

ZSCNC guarantees rigorous quality controls to meet global standards on every project. Learn more about our about page to understand our commitment.

Adaptability Across Markets

We tailor our processes to comply with diverse international regulations and market needs.

Long-Term Partnership & Risk Mitigation

ZSCNC emphasizes collaboration and proactive risk management for enduring client success.

Quality Assurance for New Projects

We apply stringent QA frameworks to ensure the success and reliability of your new initiatives. For any inquiries, please visit our contact page.